Revolution of Telematics Forklift Fleet Management

Telemetics forklift fleet management through forklifts completely alters the way business is done using material-handling equipment by creating opportunities through real-time data analytics, predictive maintenance, safety procedures, and operational optimization, thus a business can save a lot of money and increase its efficiency.

This futuristic technology captures and interprets information from the forklifts with the goal of providing a holistic, data-driven approach to Telematics forklift fleet management which eventually rewires the old methods into smart and connected systems that result in maximum safety and productivity.

What Is Telematics Forklift Fleet Management?

Telematics forklift fleet management integrate GPS tracking, sensors, wireless communication, and data analytics to provide a complete and instant picture of the location, usage, and health of not a single but all forklifts in a fleet. This leading-edge solution gives operators, fleet managers, and business owners the power of insight to: optimize operations, cut down on the equipment downtime, and raise safety levels in warehouses, manufacturing plants, and distribution centers alike.

- Telematics transform forklifts from dumb equipment into smart, self-reporting resources that must be managed differently.

- Also being data-driven, telematics forklift fleet management gets less or no time for assumptions and thus makes more scientific and result-oriented decisions.

- By guiding fleet utilization, personnel efficiency, and safety regulations telematics leads to the effectiveness of the fleet.

Features of Telematics Forklift Fleet Management:

Real-Time Data Analytics: Transforming Fleet Visibility

With telematics hardware in a forklift, the system is able to gather live data nonstop. This data include the GPS location, operating speed, operator identification, battery or fuel status, and maintenance alerts of the forklift. Such detailed insight allows performance managers to operate their teams at a much higher level and get to the solution of a problem pretty fast.

- Being able to know the exact location at all times is the best tool against theft of equipment and it also allows for more efficient planning of how the equipment will be used.

- Implanted in a different way, behavior data can be used to identify the best safety measures and catalyst for training within the safety domain, thus contributing to safety culture growth.

- Moreover, usage metrics become a helpful tool for balancing workloads, cutting down the time that the equipment stays idle, and elevating the deployment of machinery.

| Data Metrics | Benefit | Example |

| GPS Location | Efficient routing and theft prevention | Assign tasks to nearest forklift |

| Operator Behavior | Improved safety and training | Detect harsh braking or rapid turns |

| Equipment Health | Predictive maintenance scheduling | Early fault detection |

| Battery/Fuel Status | Energy optimization and reduced downtime | Optimized charging and fuel refills |

Predictive Maintenance: Cutting Downtime and Repair Costs

Telematics integration in the maintenance of forklifts changes the main idea from reactive to proactive care. It is the continuous monitoring of the health of the equipment and performance trends that makes it possible for them to detect the failure of the machine early.

- Automated alerts will be able to indicate that the machine is ready to be serviced so the breakdown that requires a large repair can be avoided.

- Besides that, maintenance according to real usage will not only prolong the lifespan of the forklift but will also reduce the occurrence of unnecessary repairs.

- Scheduling that is driven by data allows ensuring the performance of machines during the time when the production is at its lowest and thus the disruption will be minimal.

| Maintenance Aspect | Telematics Trigger | Business Impact |

| Battery Charging | Real-time battery monitoring | Avoid unplanned downtime with timely charging |

| Component Fault Detection | Sensor diagnostics | Prevent accidents and reduce emergency repairs |

| Operational Service Timing | Usage data | Increase forklift uptime and improve resale value |

Enhancing Safety and Compliance with Telematics

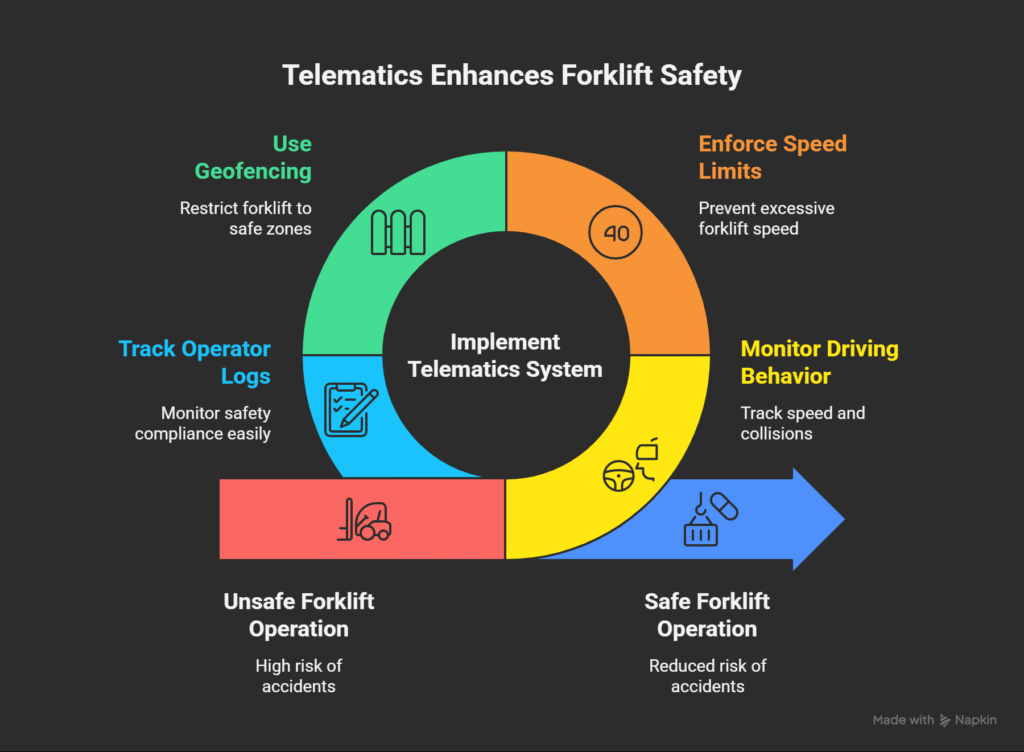

Safety is one of the biggest concerns when managing a fleet of forklifts. One of the biggest contributions of telematics is a system that monitors driving behavior, enforces speed limits, and uses geofencing to prevent forklift drive in areas that are dangerous or where there are pedestrians.

- Speed and collision warnings give more time to react thus allowing acceleration of the preventive measures against accidents in warehouses, which are usually very busy and crowded.

- Fencing done with the help of the geolocation keeps forklifts working in the zones assigned, hence, being secure both for the staff and for areas that might be easily affected.

- Specific operator logs help memory of safety compliance and ease targeted training efforts.

Key Points:

Automated monitoring brings to the fore mistakes that are typical of speeding or sudden stops such as fast drives, abrupt stops, and in some cases mishaps generated by GPS data reduction can be also detected by automatic monitoring.

- The supervisors involved get real-time information which they take immediate actions upon the event occurrence, thus excellent reaction time is assured.

- Digital safety logs are simple to manage for compliance with OSHA and insurance requirements.

Operational Efficiency and Resource Optimization

Through telematics forklift fleet management data, managers become more flexible in the allocation of resources and at the same time they manage the use of forklifts in a more efficient way they do not allow either the over-use or under-utilization of the assets to take place.

- Dispatch of forklifts is done on the basis of the real-time data on the closest task and thus the time for travel and waiting is significantly reduced.

- Moreover, identification of the idle or hardly used forklifts which is possible through the monitoring of the fleet will enable the right-sizing of the fleet as well as the reduction of the costs.

Also, the analysis of the time when most work is done will facilitate the planning of working hours as well as flow of work optimization.

| Optimization Area | Telematics Role | Outcome |

| Task Routing | GPS and status monitoring | Faster job completion, lower fuel use |

| Fleet Utilization | Usage tracking | Balance workload, cut surplus inventory |

| Labor Planning | Activity reports | Align staffing to demand, improve productivity |

Cost Savings and Return on Investment

The decision to equip a telematics system in a forklift fleet results in the lowering of observable costs through the improvement of the overall efficiency, reduction of repair expenses, enhancement of safety as well as energy consumption optimization.

| Benefit Area | Result | Impact Example |

| Energy Costs | Up to 20% reduction | Reduced battery energy waste |

| Maintenance Costs | 30% fewer emergency repairs | Better maintenance scheduling |

| Safety Costs | 40% fewer accident-related claims | Lower insurance premiums |

| Labor Efficiency | Up to 40% operator cost saving | Improved workflow and operator training |

- Thorough history of use will help the resale value of the forklift to go up.

- The safety enhancements can be a source of insurance discounts.

- By embracing the proactive approach, you get rid of those sudden operational costs.

Emerging Trends in Telematics Forklift Fleet Management

The improvements of 5G connectivity, AI analytics, and cloud computing are bringing many new features and integrating capabilities to telematics solutions. More efficient and dependable data links facilitate real-time decisions.

Also transition from single assets to mixed-asset telematics provides holistic management with the data being the integration point for forklifts, vehicles, and warehouse systems.

Operator Training and Compliance Through Telematics

Analytics regarding the performance of the operator can be one of the tools used for the targeted development of the workforce and the maintenance of compliance with the rules of safety.

- Data on driver behavior and safety incidents traced to individual operator IDs serve as the foundation for improvements and accountability.

- Safety risks and weaknesses in training identified by analytics allow the targeting and customization of safety courses.

- Automated compliance records facilitate easy audit and certification reporting.

Successful Telematics Implementation Recommendations

The most effective work is done when:

- Hard-to-move or high-risk assets are the first to be covered by a pilot program.

- Operators are involved in the process from the very beginning, and the benefits are communicated clearly.

- The platforms used for telematics are not only scalable and integrative but also compatible with the systems that are already there.

Telematics Forklift Fleet Management – Frequently Asked Questions (FAQs)

What is the purpose of telematics forklift fleet management and how does it operate?

The answer is that it is a set of sensors and wireless technology that works as a unit and in real-time it monitors the location, usage, and condition of the forklifts and at the same time it provides the management with the most properly actionable data.

Is forklift safety boosted through the usage of telematics?

Indeed. Unsafe behavior monitoring, speed limits, geofencing, and incident alerts are the means through which safety is improved and hence accidents are reduced.

In what way telematics is predictive maintenance facilitator?

By using sensor data and following usage trends to locate the point of failure before it happens and stop it there.

Telematics implementation is suitable for electric and fuel-powered forklifts, isn’t it?

Of course, a flexible system supports all major types of forklifts while the features are adjusted to their power sources.

Is it possible for telematics to bring about a reduction in the operating costs of a forklift?

Definitely. If energy use, maintenance, operator efficiency, and safety are optimized, overall costs will be lowered.

Does the telematics system provides support for the operator training and compliance?

Yes, operator identification and behavior tracking lead to better training and easier compliance documentation. Most platforms introduce APIs and plug-and-play solutions for smoother integration with the current fleet and warehouse management software.

Conclusion: Embrace Telematics Forklift Fleet Management

Telematics forklift fleet management applications for a forklift fleet is a revolutionary move that provides the exact data necessary for improving fleet safety, efficiency, and even profitability.

Employing the telematics devices is a way businesses can guarantee that every forklift will be running at its highest capacity, there will be little if any downtime, and accountability on the part of the operators will be maintained—all these factors, combined, contribute to a safer, more productive, and less expensive operation.

American Forklifts with its focus on the latest insights and reliable advice on forklifts and telematics forklift fleet management technology remains a great resource to you as a business if you are looking for ways to enhance your forklift operations through innovation and expertise.