Many warehouses and logistics organizations in the U.S. rely on forklifts a lot. But a lot of companies just repair their forklifts when they break down, which is a reactive way to perform forklift maintenance.

This is not only expensive and inconvenient, but it may also be avoided. If you want a perfect forklift maintenance strategy for your equipment functioning, make it last longer, and keep your workers safe, you need a strong forklift servicing plan.

Breakdowns Aren’t Accidents: Here’s Why You Need a Forklift Service Plan

When a forklift breaks down, production stops, workers have to wait, deadlines are missed, and money is wasted. According to figures from the industry, the average cost of downtime for a forklift is between $100 and $300 an hour. This doesn’t cover missed delivery windows, extra hours for personnel, or repairs that need to be done right away.

Why not keeping up with regular forklift maintenance is bad for business:

- More expensive repairs since little issues that aren’t treated might become huge ones.

- Machines that don’t operate properly may be harmful.

- Shortened equipment life, which might mean that a forklift’s usable life is cut short by years.

What is a service plan for a bulletproof forklift Maintenance?

A bulletproof forklift service plan is a complete, proactive maintenance plan that is tailored to the needs of your fleet, including how they will be used and where they will be used. It includes regular inspections, rapid repairs, performance tests, and updates on compliance to make sure your forklifts are always performing at their best.

A solid service plan should include:

- Maintenance Pattern: Regular maintenance that is scheduled ahead of time, such changing the oil, filters, and brakes, and more.

- Inspections on site: Trained professionals visit to your company on a regular basis.

- Logs and real-time repair monitoring: For osha forklift maintenance requirements compliance, audits, and budgeting.

A service plan doesn’t simply fix problems; it also prepares for them ahead of time so you don’t have to pay for them.

How Much Does a Forklift Cost? Service Plans vs. Breakdowns

Let’s briefly look at the differences between reactive repairs and proactive service planning. Measure for the Reactive Repair Approach Plan for Bulletproof Service.

| Metric | Reactive Repair Approach | Bulletproof Service Plan |

| Downtime Costs | $100–$300/hour | Negligible |

| Emergency Repair Fees | 25–50% more than standard | Included in service |

| Safety Compliance Risk | High | Low |

| Equipment Lifespan | Reduced by up to 30% | Maximized |

| Total Annual Cost | High and unpredictable | Predictable and controlled |

Advantages of a service plan:

- Budget predictability: The budget is easy to predict because of flat-rate or tiered pricing.

- Higher value of assets: Keep the value of resale or trade-in.

- Less liability: There are less risks of accidents and breaking the law.

Making a Forklift Safety and Performance Bulletproof

A broken forklift isn’t only a waste of time; it’s also dangerous. You might have a horrible accident if you don’t address your old tires, hydraulic issues, or steering problems. Not only does a checklist for forklift maintenance with a systematic and strategic documented maintenance plan prohibit you from breaking OSHA rules, but it also helps you keep track of service and inspection data.

A good safety servicing plan includes:

Create a DIY forklift maintenance checklist form for a clear and systematic service plan with below list:

- Checking the brakes, tires, and mast for wear before they fail.

- Checks of the battery and electrical systems on electric forklifts to make sure they don’t stop working or catch fire.

- Checking the hydraulic and lift systems to make sure they don’t fall or tip over.

Warehouses that have bulletproof plans have 40% fewer difficulties than those that don’t have established service times.

How frequently do you need to maintain your forklifts?

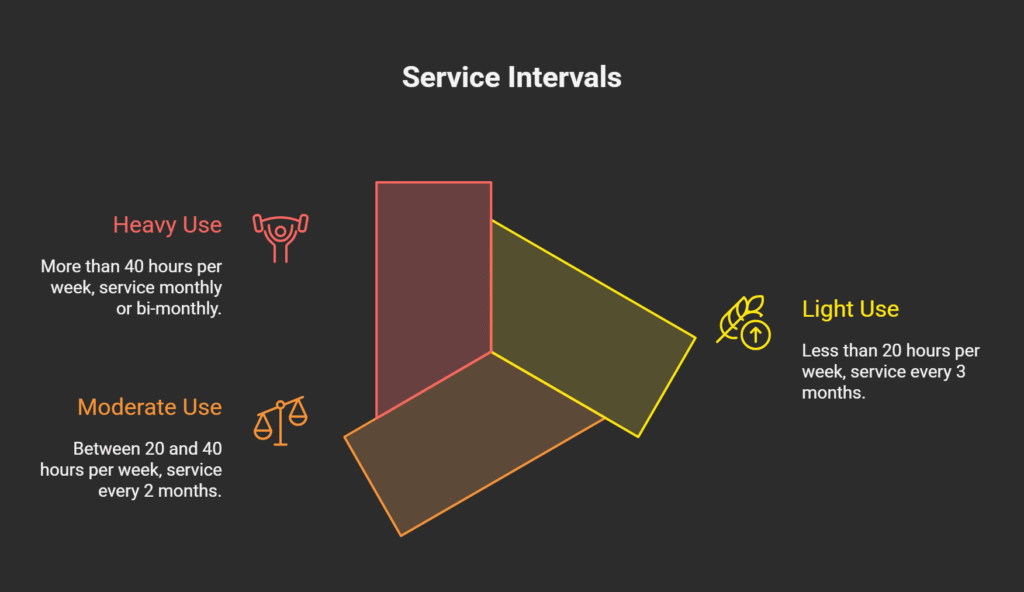

It depends on how much you use it (a little, a lot, or a lot). Most service plans are based on “hours of operation.”

| Usage Type | Hours/Week | Recommended Service Interval |

| Light | <20 hrs/week | Every 3 months |

| Moderate | 20–40 hrs/week | Every 2 months |

| Heavy | 40+ hrs/week | Monthly or bi-monthly |

Best strategies to plan forklift maintenance services:

- Always keep note of how many hours the equipment has been running.

- Check everything out before each shift to check for signs of trouble.

- Change the service based on the time of year (for example, do more inspections during busy holiday times).

Choosing the Right Partner for Forklift Repair

Not all service providers are the same. Choosing a partner that understands your fleet, offers flexible plans, and employs trained technicians might make a major impact.

Things to look for in a Forklift maintenance company:

- Technicians that have been trained by the company that made your forklift and have credentials for it.

- Easy-to-use tools for keeping track of maintenance expenditures and data.

- The time it takes to respond to an emergency is 2 to 4 hours.

Your supplier should be more than just a contractor; they should be an important part of your business strategy. AmericanForklifts.org suggests you should work with service companies who provide maintenance plans that may expand with your demands.

How to Know Your Forklift Needs Service Right Away (Even If You Have a Plan)

There might be problems that crop up between service intervals. You can save a lot of other problems from arising if you discover them early.

You should never ignore these warning signs:

- The raise or lower motion is jerky or slow

- There are weird noises while the machine is working

- There are leaks around the hydraulic or transmission sections

Make sure your operators know how to find these issues and tell you about them straight away. An active service plan also includes emergency callouts and urgent diagnostics.

Benefits Beyond the Machine: Culture, Compliance, and Trust

A service package includes more than just equipment. It’s about building a culture of caring and professionalism. Your staff will be more satisfied with their job if they see that the tools are being taken care of. You’re ready for the OSHA inspection. You have information when consumers ask about reliability.

Some indirect but major benefits of a service plan include:

- Operators are happier and there is reduced turnover.

- Less punishment for not following the rules and failing audits.

- A better reputation for being dependable in the supply chain.

All of this makes the company more adaptable and ready to develop.

Don’t Wait for the Breakdown: The Ultimate Forklift Maintenance

A forklift service plan is better than insurance since it prevents problems from happening in the first place. One of the finest things you can do for your company is to get a bulletproof forklift servicing plan.

You never know how much will forklift maintenance costs for the repairs, how safe they will be, or how long they will be out of service. No matter how large or small your warehouse or distribution center is, you need to be proactive if you want to be successful.

Don’t let breakdowns stop you from doing your work. Don’t forget to include forklift maintenance in your strategy; it’s important.

FAQ’s: Forklift Maintenance Plans for service that are bulletproof

How much does a service plan for a forklift cost?

Prices vary according on the provider, the size of the fleet, and how good the service is. You could anticipate to spend between $75 and $150 per month for each forklift on average.

Is it possible for me to repair forklifts myself?

Yes, but you need to make sure you have certified technicians and documentation that follows OSHA guidelines. Third-party plans make sure that everything is done well and that experts keep an eye on things.

What kinds of forklifts could be covered?

Most vendors cover well-known brands including Toyota, Hyster, Yale, Crown, Komatsu, and Mitsubishi.

Does completing regular maintenance have an effect on the warranty?

Yes, if you don’t take care of anything, the manufacturer’s guarantee may not be valid. Service plans protect your warranty and the value of your car when you sell it.

What does a typical service visit for a forklift include?

Checks of the performance, inspections, fluid top-offs, filter changes, battery checks, and tire pressure.

How can I keep track of logs for maintenance?

Good suppliers let you see service records and get reminders in real time using mobile apps or digital portals.