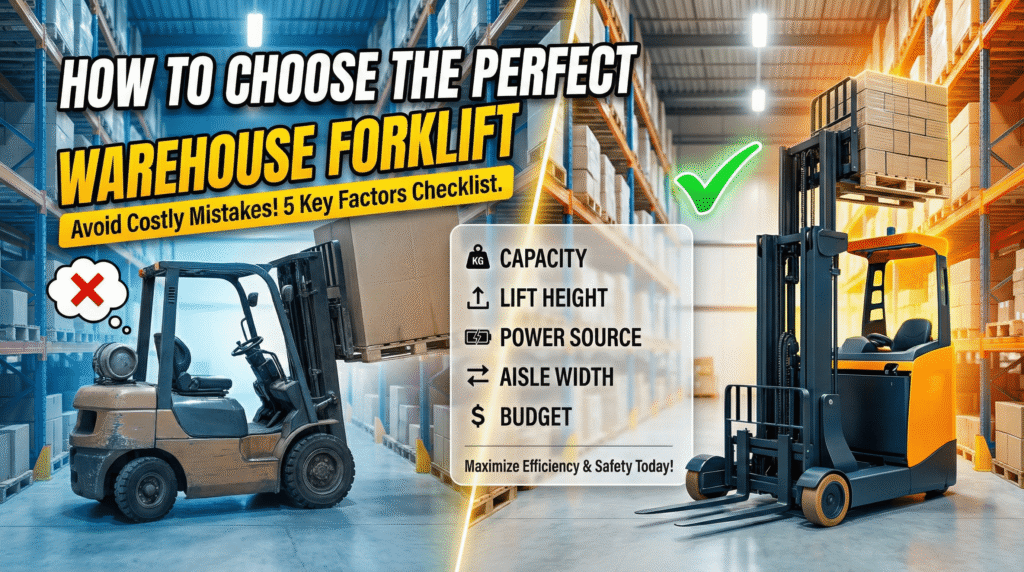

How to Choose the Perfect Warehouse Forklift

The process of selecting heavy equipment suitable for your facility is not only crucial but also a decision that directly influences efficiency, safety, and profitability. Just like in the construction industry, a roller compactor is necessary to build a firm base, in the same manner, a warehouse forklift is at the core of material handling in logistics and warehousing.

Finding the right piece of equipment is not as simple as it looks. It calls for understanding your operations, facilities, and resources. This detailed manual features the main points that should be taken into account when buying a warehouse forklift.

Assess Your Warehouse Layout and Environment

It is absolutely necessary to be very clear about the physical surroundings before you start narrowing down the field of warehouse forklift models. One major factor determining the type of machinery you can successfully deploy is the layout of your facility.

For example, if maximizing storage space results in a warehouse with very narrow aisles, you would be unable to safely operate a standard counterbalance forklift as the machine would be too large.

However, if you have an extremely large facility with open spaces, you can choose any type of equipment without being concerned about space. The surface and condition of the floor are of prime importance too since just like in the compaction of soil and other surfaces where the steadiness of the ground dictates the kind of vehicles that can run on it, a warehouse forklift needs a flat hard surface to be used without any hazard and this is more so when the lift is at great heights.

- Aisle Width: Accurately measure the distance between your racks. Usually, standard forklifts require aisles of at least 12 feet. For example, reach trucks and narrow aisle forklifts can be used in aisles as narrow as 8 to 10 feet.

- Floor Surface and Condition: Identify whether your floors are concrete, asphalt or outdoors. The choice of tires and suspension will be influenced by this. If the surface is not properly leveled or compacted, one can expect that the stability of the lifts will be compromised.

- Overhead Clearance: Measure the height of your doors, sprinkler system, lowest beam, etc. You should ensure that the warehouse forklift’s mast height when lowered, is such that it can clear all the possible obstacles and at the same time be able to reach the highest rack levels.

Determine Load Capacity and Lift Height Requirements

Without realizing it, you could misjudge your requirements for load capacity with a warehouse forklift. It is crucial that the forklift of your choice comfortably accommodates your heaviest load without you having to worry about the safety factor.

In fact, frequent operation at the limit of a machine’s capability means wear and tear will be faster and that sudden failure can occur. Plus, the fact that forklift capacity diminishes with increasing load height (a phenomenon called derating) needs further consideration.

It is not enough to have a forklift that can do either of these two – lift the full weight or lift to the full height. You have to consider what the combination of these two parameters will be.

For instance, if you have heavy long items (such as lumber or pipes), your effective load center will be beyond 24 inches, so the actual capacity of your forklift to handle such loads is greatly reduced.

- Maximum Load Weight: You need to estimate the weight of the heaviest pallet you have and then add a few extra pounds for safety. So, if your maximum load is 4,500 lbs, even a 5,000 lb capacity warehouse forklift may not be able to lift the maximum height safely whereas a 6,000 lb model would be much safer.

- Maximum Lift Height: Record the height of the highest rack on your floor and then add 6 to 8 inches which is the standard for lifting clearance. Make sure your different mast types (2, 3, or 4-stage) can accommodate your required height without hitting the ceiling.

- Load Center: Understand what your load dimensions are. Typically warehouse forklifts’ standard load capacity is set for a 24-inch load center. However, if your loads are longer, such as wood or pipes, the forklift capacity drops significantly.

Select the Right Fuel Type: Electric vs. Internal Combustion

The power source dilemma between electric and internal combustion (IC) engines has become one of the most important topics in the material handling industry. While it is true that IC forklifts (diesel, LPG, gasoline) have traditionally been touted for their power, the electric warehouse forklift technology has come a long way very quickly.

Because they do not emit harmful gases and make less noise, electricity-powered forklifts are now the preferred choice for indoor use. They run on either lead-acid or lithium-ion batteries and their maintenance costs tend to be low over time as they have fewer mechanical parts to wear out. Nevertheless, IC forklifts are still better suited for outdoor use with heavy-duty cycles when the user cannot afford charging breaks.

- Indoor vs. Outdoor Use: Electric forklifts are a must indoors to ensure the air quality is good. IC forklifts are more appropriate for outdoor areas or well-ventilated ones. Apart from that, he IC models can better withstand exposure to rain and dirt than regular electrics.

- Total Cost of Ownership: Electric warehouse forklift models typically have a higher initial price (due to the battery and charger), however, thanks to the greatly reduced fuel and maintenance costs, they often come out cheaper in the long run over a period of 5+ years.

- Refueling Convenience: Refueling IC forklifts is a matter of minutes when propane tanks are swapped or filled. In contrast, electric forklifts need to be charged although “charging when there is an opportunity” that is being practiced with lithium-ion batteries is mitigating this problem.

Tire Selection: Cushion vs. Pneumatic

Since tires are the only part of your warehouse forklift that comes in direct contact with the floor, they play a big role in the stability and security of the vehicle. Just like in the case of soil compactors, which are chosen depending on the soil types – small steel wheel compactor for gravel versus a padfoot compactor for soil – proper matching of forklift tires and flooring is very important.

Cushion tires are solid rubber and used primarily on indoor, concrete floors. Besides, they have a tighter turning radius which is quite handy when negotiating tight warehouse spaces. Pneumatic tires, on the other hand, are either air-filled or solid rubber and provide better traction and shock absorption on uneven or outdoor surfaces.

- Cushion Tires: These are perfect for indoor uses on smooth surfaces. Not only do they last a long time, but they also enable the forklift to be closer to the ground, thus offering better balance for higher lifts.

- Pneumatic Tires: They are the tire of choice for outdoor or rough asphalt. Pneumatic tires, in contrast to cushions, take up the impacts better thereby safeguarding the operator and the load. The drawback though is that they enlarge the turning radius of the warehouse forklift.

- Non-Marking Tires: If your company is in the food, pharmaceutical industries, or has specialized flooring that has to be kept clean elimination of black rubber marks on the floor by means of non-marking tires is an absolute requirement.

Ergonomics and Operator Comfort

It is generally accepted that a happy, healthy worker is a more effective and safer worker. The latest warehouse forklift designs have a real focus on operator comfort and to that end incorporate anti-fatigue measures to make extended shifts easier.

The features that seem to be pure indulgence at first sight like a suspension seat, adjustable armrests, and easy-to-get controls help, however, with getting the job done each day. On the other hand, poor ergonomics can trigger musculoskeletal disorder and lowered alertness which can lead to an accident.

Think about the employee’s “office” that they will spend their entire day in when picking the machine. Besides, driver’s seat visibility is a safety-related feature that is considered highly important; the design of the mast must enable a clear view of applications, the road, and forks.

- Cab Design and Controls: Make sure the cab has a lot of legroom, low step heights to make entry/exits easier, and hydraulic levers that are easy to reach. You can ease your arm strain if you choose fingertip controls rather than the large mechanical levers.

- Visibility: The mast system should be designed in a way that it does not interfere with the operator’s view of the load. Operating a warehouse forklift with limited visibility not only prevents the driver from seeing where he is going but also increases the chances of hitting goods and damaging racks or even pedestrians.

- Vibration and Noise Reduction: Quality machines have the motor and cabin well-isolated so that the operator gets minimum vibration transferred to his spine. The lesser the noise level, the better communication and less long-term hearing damage.

Evaluate New vs. Used and Budgetary Constraints

Of course, your budget will constrain your final decision to some extent. When you buy a completely new warehouse forklift, you get the most modern technology, highest performance, and a warranty directly from the manufacturer.

On the other hand, it can be a large upfront cost. For those companies who do not have money to give up or the truck is for a few hours use only, a great used or refurbished forklift can be the solution to your problems.

In case you decide to buy used, you should be really careful, and it is better to have a checklist for inspection that covers mast rails, hydraulic hoses, and battery condition.

- Utilization Rate: A new forklift will be your best bet if it will operate for 4+ hours/day so as not to cause downtime issues. On the other hand, if you are going to use the forklift lightly (like 1 or 2 hours a day), the used one will give you a better return on your investment.

- Warranty and Support: The new units are backed up by a full and comprehensive warranty (typically 2 years/2000 hrs). To get it otherwise, you have to buy brand new but the used ones are sold “as is” or with a very small warranty which is limited your risk exposure.

- Financing Options: You may check out both leasing and purchasing. If you use the leasing warehouse forklift model, you can save your money and upgrade to the new one every few years, which is a great way to stay up-to-date with the technology.

Maintenance and After-Sales Service

Even the heaviest-duty warehouse forklift will call for maintenance at some point. However, the proximity of the dealer and their credibility is just as important as the brand itself. A forklift waiting for its ordered part is one of the worst liabilities that cause a complete standstill in operations.

Make sure the manufacturer you choose has a network of service centers nearby. From your experience with a roller compactor or other heavy equipment, you would agree that expert service is essential. Therefore, a good partner in the maintenance of your forklift, preventive as well as emergency, is very desirable.

- Parts Availability: Check that there is a local stock for the few parts most commonly subjected to wear and tear (tires, filters, hydraulic seals). By the virtue of their market footprint, the major brands have a more reliable and uninterrupted parts supply chain.

- Service Response Time: Inquire with the dealer about the typical turn-around time on their call-out services. Usually, critical operations come with a 4-hour guarantee.

- Maintenance Contracts: You may want to consider doing PM (Planned Maintenance) agreement with a certified technician who inspects your warehouse forklift at regular intervals and thus can identify small faults before they escalate into expensive breakdowns.

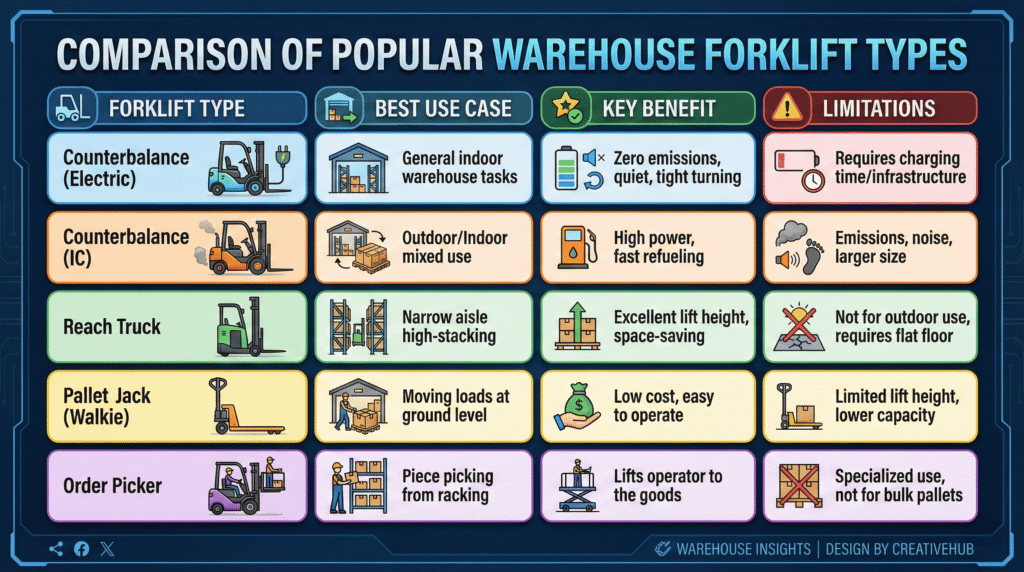

Comparison of Popular Warehouse Forklift Types

| Forklift Type | Best Use Case | Key Benefit | Limitations |

| Counterbalance (Electric) | General indoor warehouse tasks | Zero emissions, quiet, tight turning | Requires charging time/infrastructure |

| Counterbalance (IC) | Outdoor/Indoor mixed use | High power, fast refueling | Emissions, noise, larger size |

| Reach Truck | Narrow aisle high-stacking | Excellent lift height, space-saving | Not for outdoor use, requires flat floor |

| Pallet Jack (Walkie) | Moving loads at ground level | Low cost, easy to operate | Limited lift height, lower capacity |

| Order Picker | Piece picking from racking | Lifts operator to the goods | specialized use, not for bulk pallets |

FAQs – Warehouse Forklift

How do I determine which forklift my warehouse needs?

You can determine the right warehouse forklift by first identifying the maximum weight of the load to be carried, the height of the top shelf, and the width of your aisles. Also, you have to think about your workspace being indoors (electric) or outdoors (IC). If you want to be very thorough, a professional dealer will survey your site and take into consideration other factors that you might overlook such as the height of your doors or weight limits on the floor.

Are electric forklifts more cost-effective than diesel forklifts?

To a certain extent, for indoor warehouse operations, electric forklifts are more cost-efficient. Even though the initial cost will be more expensive due to the battery, they incur higher running costs because of the fuel and maintenance (no oil changes and fewer moving parts) than diesel or propane forklifts.

What load capacity do I need for my forklift?

The capacity you choose for your warehouse forklift should be higher than your average load weight. Let’s say your heaviest pallet load is 4,000 lbs, in such a case, a 5,000 lb capacity unit will be perfect.

What is the difference between cushion and pneumatic tires?

Cushion tires are made of smooth, solid rubber and are intended for indoor use on smooth concrete floors; they have a tighter turning radius. Pneumatic tires are similar to car tires (air-filled or solid) and are intended for outdoor use or rough surfaces, providing better traction and impact absorption.

How does aisle width affect forklift selection?

Aisle width is one of the most important factors that determine what kind of forklift you can have. This is because a counter-balance standard warehouse forklift needs an aisle width of 12-14 for a full turn. On the contrary, if your aisles are narrower (8-10), you have to opt for a reach or narrow aisle forklift. If this is ignored, you would eventually have a machine that cannot physically fit into your stacked pallets.

Should I rent or buy a forklift?

When you have a short-term project, a seasonal peak or limited capital, renting is an option that gives you flexibility and includes maintenance service in the cost. However, if the forklift is part of the core daily operations and it is going to be used for 5+ years, then purchasing or leasing is more financially advantageous over the asset’s life.

What safety features should the best warehouse forklifts include?

If you want to get the best, the Operator Presence System (that will automatically disable the hydraulics if the operator leaves the seat) plus blue safety spotlights for pedestrians, backup alarms, and a mast being highly visible are some of the features that come to mind. It goes without saying that seat belts and overhead guards are part of the standard safety features and are considered mandatory.