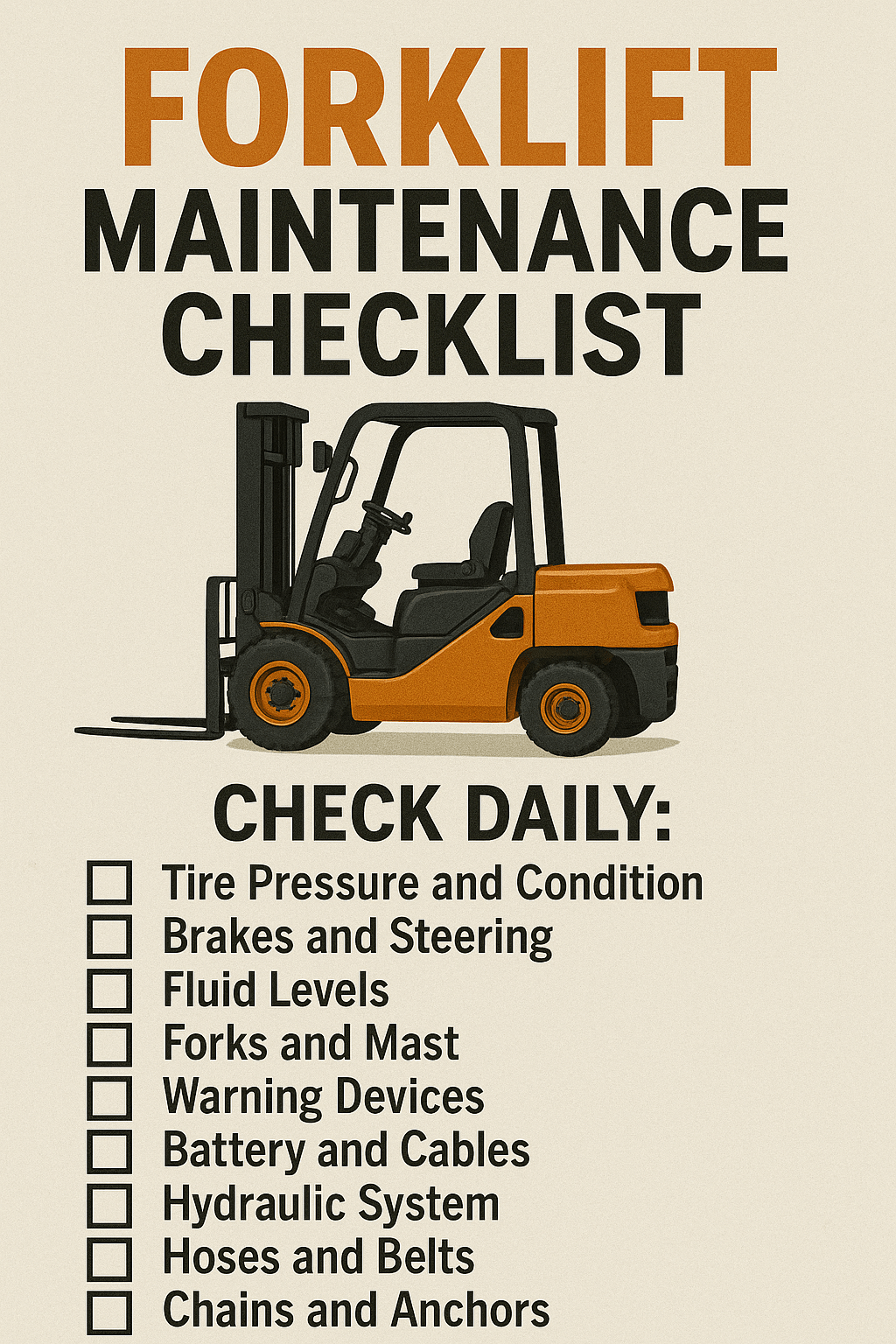

Forklift Maintenance Checklist Included

Warehousing, logistics, and manufacturing are three closely connected fields of work that are the most dynamic in the world owing to the rapid advancement in technology. The workforce and the machinery are always at work, such as forklifts that are tirelessly lifting, moving, and stacking heavy loads.

They are the lifeblood of many operations, and like any critical piece of machinery, they rely on regular, high-quality maintenance to achieve efficiency and longevity. Skipping forklift service isn’t just a small thing an operator forgot to do, but a big deal, as it can lead to many losses, the most common being a breakdown, decreased productivity, safety issues, and finally, a reduced income.

Forklift Maintenance Importance:

For us at American Forklifts, we believe in the huge impact these units have on daily operations and only that way could we possibly help you in the best way possible to answer the very most important questions of any forklift owner or operator: “How often should you service your forklift?”

As an immediate response, we added the latest maintenance checklist that will equip you and your forklift to be in a good and reliable condition resulting in zero downtime and longer life.

The Million-Dollar Question: How Often is “Often Enough”?

It’s definitely the case that there cannot be a universal format in terms of servicing your forklift for every business size or shape. The most effective times for maintenance is constantly changed, determined among various critical factors that influence the business. Make it similar to a piece of clothing that is perfectly tailored to fit your specific operational goals, rather than being concerned about a one-size-fits-all approach which doesn’t suit you at all.

Key Factors That Establish Your Particular Forklift Service:

Usage Hours:

The most argued factor is the number of hours. A truck that is used 8 times every day, 5 days a week will definitely need a lot of service when compared to one that is used only occasionally and for a few hours.

The majority of manufacturers stipulate service intervals in relation to operational hours (e.g. every 200, 500 or 1,000 hours). Ultimately, keep a record of the operational hours of your forklift.

Operating Environment:

- Clean and Controlled: It is a fact that a forklift that operates in a temperature-controlled, clean warehouse will have few mechanical issues, and will undergo less tear and wear as well.

- Dusty/Dirty: That is to say, places which are packed with the remnants of a construction site, the dirt from a lumber yard and the extreme dust are the dirt and debris that are contaminating the air can force the filters of a lift truck to be clogged. This is not the end. The fluids also get contaminated and the wear is accelerated through having these components. Such forklifts will have to be checked and cleaned more.

- Extreme Temperatures: Operating in extremely hot or cold conditions will influence the hydraulic systems, storage batteries, and engines negatively and thus closer inspection is necessary.

- Corrosive Materials: Being exposed to chemical agents or corrosive materials will result in direct damage to the material of the forklift, and therefore, specialized cleaning and inspection are mandatory to avoid material degradation.

General Guidelines for Forklift Service Intervals

As the exact answer will depend on the factors given above, we will name just a few more general parameters for the regular service intervals:

- Daily/Shiftly (Pre-Operation Checks): These are quick visual and functional checks carried out by the operator before each shift. They are vital for the on-time detection of problems.

- Once In 200-250 Hours (or Monthly): Now, this is a light preventive maintenance service earned by the lift truck. Hence, it involves checking the level of the fluids, a little grease application, filter inspections, visual checks, and a visit to the key components.

- Once Every 500 Hours (or Quarterly): More substantial type of service like, for example, oil changes, (air) filter replacements (gas, air, fuel – for IC forklifts), hydraulic fluid checks, and many more deep inspections of the brakes, tires, chains, and electrical systems may be done.

- Biennially/Triennially Once in 1,000-2,000 Hours (or Annually): This sort of service is by far the largest, usually called an annual inspection. So it is all the 500-hour service and also a more comprehensive check of the steering components, differential fluid, the mast components, as well as the engine tuning (for IC forklifts), and the battery capacity testing of the electric forklifts.

- Once Every 4,000-6,000 Hours (or Biennially/Triennially): This may include major overhauls depending on the truck and frequency of use, e. g., the flushing of the hydraulic system, engine tune-ups, and minor component rebuilds.

Remember: These are general guidelines. Your specific operational needs and manufacturer recommendations must always take precedence.

Mast & Carriage Inspection:

The careful checking of the mast, being guided by rails, engaging chains, cylinders, and hoses. Inspect the load for weakening, bending, or wear that is beyond ordinary will be part of the conduct. Apply grease to all mast components.

- Engine Tune-up (IC Forklifts): Inspecting the exhaust gases, the clearance of valves, ignition timing, and adjustment of the fuel system are among the constituents of the service for internal combustion forklifts.

- Load Chain Inspection: Elongation, wear, and corrosion are the flaws that you will look for through a thorough inspection of the load chains. In case of the need for replacement, do it.

- Electrical System Diagnostics: A complete review of all wirings, connections, controllers, and sensors for faults.

- Battery Reconditioning/Replacement (Electric Forklifts): Check the battery’s functionality and its remaining usefulness and decide whether you should recondition or replace it.

- Thorough Cleaning: The cleaning should from now on be deep, where all the components were thoroughly cleaned, especially the radiator and the engine compartment.

- Safety Device Recalibration: Double check that your safety systems are fully operational and calibrated well.

The Benefits of Proactive Forklift Maintenance

Deploying a robust forklift maintenance program does not mean a company is spending money that can’t be recovered. Instead, they are making a strategic investment that will pay off with good dividends, and here is how:

- Enhanced Safety: First and foremost is safety. Regular maintenance of forklifts makes them less prone to accidents and casualties due to breakdowns and other factors that lead to the damage of the vehicle and its parts.

- Increased Uptime & Productivity: By doing maintenance at the right time, you help gather problems so they can be solved before they grow into big ones, simultaneously allowing you to keep moving your business in a streamlined slow down manner.

- Extended Lifespan of Equipment: Continual maintenance slows the rate of wear and tear of your vehicles significantly and as a result, the lifespan of the vehicles can be considerably prolonged.

- Reduced Repair Costs: Taking care of small matters when they are just about to develop is way less expensive than when they have already developed and are on the verge of spreading, which would have been involving part, the things will go way beyond but will also be much more costly.

- Fuel Efficiency and Battery Life: Increased Fuel Efficiency (IC Forklifts) & Longer Battery Life (Electric Forklifts) A well-maintained engine and a properly-operated battery are more environmentally friendly, which lowers your costs significantly.

- Compliance with Rules: Regular maintenance is practical. It ensures the safety of the equipment and its compliance with the OSHA and industry standards and regulations.

- Higher Resale Value: A properly maintained equipment is likely to have its resale value increase either at an auction in a different format or in a market in the future.

Partnering with American Forklifts for Your Maintenance Needs

Setting up a complete forklift maintenance program and its efficient running can be a strenuous chore especially for those enterprises that are running large fleets of vehicles and have limited in-house expertise. To alleviate those concerns, American Forklifts is highly equipped.

Our wide range of forklift service and maintenance solutions is not the only reason why we are the right partner for you. There is a variety of areas where our service is superseded to cater for the peculiar needs of each client, these areas are:

- Preventive Maintenance Programs: Regularized plans decided by our team based on your usage, environment, and forklift types are what we offer.

- Immediate Repair Services: Quick action is a key aspect of the maintenance of your equipment. Our response team will help fix the problem that has risen unexpectedly within a short time meaning that you do not have to spend much time being idle.

- Qualified Technicians: The very experienced and trained technicians that our company offers fix all kinds of machines that you may have.

- Original Products: Your forklift is made of quality materials only and that is our assurance to you for your safety and high operation of the machine.

- Monitor Service History: All of the specifications for the product will be provided to you in a detailed manner so that you can maintain a well working product or have it all filed for your records and compliance’s sake.

- Fleet Management Solutions: Our fleet management solutions are there to help you manage your forklifts’ usage, services scheduling, and their best possible performance.

One should therefore ensure regular maintenance and make sure that one’s forklift isn’t dangerous to handle due to loopholes. With regular servicing in mind and the support of a reliable supplier like American Forklifts, one can keep their forklifts in the best possible state, so that they are still safe, operational and can fully meet the requirements of the operation.

We are available for consultations at AmericanForklifts.org to talk about your forklift maintenance needs and tailor a service program that will be beneficial for your business. Consult us for the step to expand it in less time and feel free to keep your cash at hand by protecting your investment from now on.

Frequently Asked Questions (FAQs) About Forklift Maintenance

Q1: How often should a forklift be serviced?

A1: Depending on usage, the environment of operation, forklift type, and the forklift being like new or old, the frequency of maintenance varies. The rule of thumb is that operators perform a pre-operation check every day. And then more elaborate service interventions every 200-250 hours (monthly), 500 hours (quarterly), and 1,000-2,000 hours (annually). It is advisable to follow your manual for the manufacturer’s recommendations.

Q2: What is included in a typical forklift preventative maintenance (PM) service?

A2: A typical PM Service comprises of the following: the level of the liquids (engine oil, hydraulic fluid, brake fluid, coolant) is verified and refilled, the filters (oil, air, fuel, hydraulic) are examined and replaced, all moving parts are lubricated, safety and electrical systems are checked, and a test of the tires, brakes, chains, mast components, and the functionality of all other features is performed. The extent of the service varies according to the hours of the machine.

Q3: Is it feasible for my employees to look after forklift maintenance activities, or should I hire a professional service?

A3: No doubt, if the mandatory daily check before work can be done by a certified operator, the rest should be done by a technician qualified in forklift services. This applies not only to daily routines but also to every larger or smaller machine issue such as fluid changes, brake inspections, hydraulic system checks, or engine tuning. This technician should be competent and reliable in the ways of the performing manufacturer’s maintenance processes, safety precautions, and adherence to manufacturer specifications.

Q4: What will my negligence of regular forklift service cause?

A4: Avoiding regular service can result in many problems such as increased hazards of accidents and injuries, frequent and costly breakdowns, reduced forklift lifespan, decreased operational efficiency, higher fuel or energy consumption, and potential non-compliance with safety regulations (like OSHA).

Q5: How can I determine the hours of use for maintenance purposes on my forklift?

A5: Almost all modern forklifts are equipped with hour meters. The necessary thing is to keep a record of these hours regularly. With regard to large fleets, it is advisable to use a specialized fleet management software that will monitor the usage and at the same time proactively schedule the services or a system for manually tracking the process.

Q6: Do electric and internal combustion forklifts have the same type of maintenance requirements?

A6: No, there is definitely a great difference between the two. The IC forklift needs all the maintenance related to the engine (oil changes, spark plugs, fuel systems) while the electric forklift is mainly focused on the battery (watering, cleaning, load testing), electric motors, and controller diagnostics. However, both categories are to undergo hydraulic and mechanical system checking.

Q7: How much does forklift service cost?

A7: The amount of money for forklift service fluctuates extremely with the type of service (just a casual check up to a complete rebuild), the brand of the machine, the required parts, and rates of pay for labor. A preventive maintenance schedule is generally a consistent, low-cost item, but an emergency repair could be unpredictable and the cost much higher. Typically, it is more profitable to pay for a PM program than for frequent mishaps in the long term.

Q8: What is the most important part of a forklift to maintain?

A8: It is true that for a safe operation the brakes, mast, and lift chains are the most important things, as the battery for electric forklifts and the engine for IC forklifts are not to be forgotten also for efficient operation. The major part is the everyday pre-check as no other activity is as essential as this one.

Q9: Does regular maintenance impact the resale value of a forklift?

A9: Definitely. Forklift in good order serviced with all records of the service account for a lot more when selling than one that does not have these services attributes. It is an obvious indication that the equipment is in good condition and would work efficiently in the future to potential buyers