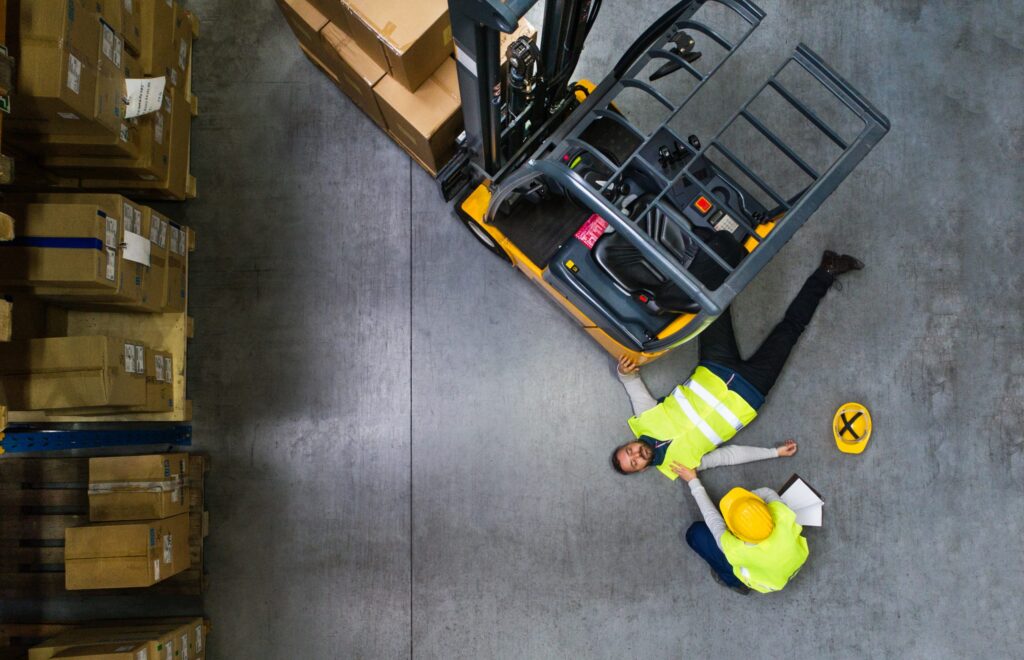

Forklift accidents can have serious consequences, highlighting the importance of safety in handling this heavy-duty machinery. Even with stringent industry regulations, understanding What Are The Most Common Causes Of Forklift Accidents? is crucial. This article explores the frequent factors that lead to these accidents and offers actionable steps to mitigate risks, ensuring a safer operating environment.

Common Factors Leading to Forklift Accidents

Understanding the common causes of forklift accidents is the first step towards creating a safer working environment. These factors can be categorized into five main areas: behavioural, organisational, environmental, mechanical, and load-related problems.

Behavioural Factors

The behaviour of forklift operators significantly impacts safety. Common behavioural issues include:

- Lack of Communication: Failing to communicate with others in the vicinity can lead to collisions and other accidents.

- Excessive Speed: Driving too fast reduces reaction time and increases the risk of accidents.

- Elevated Loads: Operating a forklift with an elevated load can cause instability.

- Improper Use: Performing tricks or using the forklift for unintended purposes is dangerous.

- Improper Parking: Not parking the forklift properly can lead to accidents.

- Poor Handling: Failing to follow proper procedures when backing up, turning, or braking.

Mechanical Problems

Maintaining forklifts in good working order is crucial for safety. Key points include:

- Regular Maintenance: Services and repairs must be carried out regularly to prevent malfunctions.

- Pre-Use Inspections: Operators should inspect forklifts before use to identify any issues.

- Timely Repairs: Any malfunctioning forklift must be repaired before it is used again.

Organisational Factors

Organisational practices can also influence forklift safety. Examples include:

- Operator Stress: Overworked or overstressed operators are more prone to mistakes.

- Insufficient Training: Lack of proper training can lead to improper forklift use.

- Cutting Corners: Encouraging operators to rush their tasks can compromise safety.

- Poor Maintenance Practices: Neglecting forklift maintenance can lead to unsafe conditions.

- Delayed Replacements: Failing to replace outdated forklifts increases the risk of accidents.

Learn More: 7 Must-Have Forklift Safety Accessories

Load-Related Problems

Handling loads improperly is a common cause of forklift accidents. Issues include:

- Overloading: Carrying loads that are too heavy can cause instability.

- Unstable Loads: Unstable or broken pallets can lead to accidents.

- Obstructed View: Loads stacked too high can obstruct the operator’s view, creating hazards.

Environmental Factors

The work environment plays a significant role in forklift safety. Factors to consider are:

- Busy Areas: High activity levels can increase the risk of accidents.

- Cluttered Spaces: Obstacles in the area can impede safe forklift operation.

- Ramps and Slopes: Negotiating ramps and slopes requires extra caution.

- Poor Lighting: Insufficient lighting can lead to visibility issues.

- Distractions: Loud noises, bad odours, and other distractions can affect operator focus.

- Dust and Debris: Dusty environments can impair visibility and machinery function.

- Narrow Aisles: Operating in tight spaces requires careful maneuvering.

- Varied Surfaces: Different surface conditions can affect forklift stability and control.

How to Avoid Forklift Accidents

Creating a safe forklift environment requires understanding the contributing factors and implementing measures to mitigate these risks. Here are some strategies:

- Training and Communication: Provide comprehensive training and encourage open communication among workers.

- Regular Maintenance: Ensure forklifts are maintained and inspected regularly.

- Safe Practices: Promote safe operating practices and discourage shortcuts.

- Proper Load Handling: Educate operators on proper load handling techniques.

- Environment Management: Keep work areas clean, well-lit, and free from obstacles.

Learn More: Common Forklift Problems & How To Avoid Them

Team Effort for Safety

Safety is a collective responsibility. By fostering a culture of safety, providing proper training, and ensuring regular maintenance, organizations can significantly reduce the risk of forklift accidents. Making safety a priority not only protects workers but also enhances overall productivity and efficiency.