Electric Forklift Warranty Guide: What Coverage Should You Demand?

Purchasing an electric forklift is a big-financial step for any material handling business, and thus, protecting that investment needs more than just good maintenance. A thorough Electric Forklift Warranty is your main protection against unforeseeable manufacturing defects and expensive parts failures.

While exploring your options for the perfect lift truck, you get so caught up in the load capacities, lift heights, and ergonomic features that you almost forget that warranty terms often determine the machine’s value over time and Total Cost of Ownership (TCO).

It is crucial to grasp electric forklift warranty coverage details, from battery pack to hydraulic systems, so that you don’t end up with an enormous repair bill for a breakdown that really should have been covered. In this post, we are going to go through the key points of warranty coverage that you should obtain to keep your fleet both running and making money.

Understanding the Different Types of Electric Forklift Warranty Coverage

It’s probably rare that when buying a brand-new or certified used electric forklift, the warranty will only be one uniform policy. Usually, it will refer to certain parts that are divided into sections, and each section specifies the duration of the warranty for each of the parts.

Knowing these differences will help you extend the life of your fleet and set aside money for future repairs. The major three levels of marketing by most manufacturers are Standard, Powertrain, and Extended warranties.

- Standard Carriage-to-Counterweight Warranty: This is equivalent to a “bumper-to-bumper” warranty in the car industry. It usually provides a short time period of 12 months or 2,000 operating hours during which the whole machine is covered against defects in material and workmanship.

- Powertrain Warranty: This type of warranty is focused on the most costly parts and lasts for a considerable time, perhaps 3 years or 6,000 hours. It emphasizes expensive and essential components of the vehicle, such as the electric drive motor, transmission, and differential as well as the components directly related to the forklift’s core movement.

- Extended Warranty Options: If your business runs at high-intensity applications, being able to buy an extended warranty gives you a peace of mind that goes beyond the standard terms. You can significantly add years to your coverage with these tailored packages but it is advisable to check in detail if they really offer value.

The Heart of the Machine: Electric Forklift Battery and Charger Warranties

The battery is by far the most important and costly part of an electric forklift, since it can make up as much as 30% of the truck’s value. Hence the Electric Forklift Warranty on the battery and charger is worth more than a cursory glance.

Transitioning from traditional lead-acid batteries to more efficient lithium-ion technology is taking place in the industry and the warranty differences between these two power sources are significant. It is necessary that you ensure the warranty covers capacity retention, i.e., the battery’s ability to hold a charge, for a given number of cycles.

The lead-acid battery is generally covered for 2 to 5 years, but there is usually a declining value (pro-rated) structure incorporated. In other words, if the battery fails in the 4th year, you may only get a partial credit on the replacement rather than a new battery for free.

This excellent battery is usually provided with a very strong warranty, lasting 5 to 10 years or even up to 10,000 hours. You should seek warranty conditions that ensure that the battery will retain not less than 80% of its original capacity during the warranty period.

Don’t forget about the charger! A defective charger can ruin a good battery. Confirm that the charger is warranted separately and that this warranty lasts for a reasonable period, usually 1-2 years, which is the same as the standard equipment warranty, thus avoiding any compatibility disputes.

Critical Components That Must Be Covered

Besides the battery, an electric forklift contains complex electronic components such as controllers, hydraulic pumps, and motors. Negotiating your Electric Forklift Warranty it is essential to confirm that those high-value parts are specifically included.

Brands sometimes mean to designate some types of electronics as “wear items” so that they do not have to make parts replacement payable, thus it is imperative that you carefully scrutinize the list of exclusions. A nice warranty will unambiguously enumerate the main assemblies to make sure there is no misunderstanding at the time of the claim.

The hydraulic systems are composed of the lift pump, cylinders, valves, and hoses which are inevitably subjected to heavy work. A warranty for these components is one of the things that you must definitely have since hydraulic failures may lead to a stoppage of the machine and could also cause hazards to people’s safety.

- Electronic Controllers and Inverters: Being the “brains” of an electric forklift, these components require a high level of care. To replace a main logic controller can cost a fortune, thus it is essential that electronic components such as these are in the powertrain or a separate electronics warranty.

- Electric Motors (Drive and Lift): While electric motors do not have as many parts that get worn down as an internal combustion engine, they can still suffer from overheating or internal shorts. Your warranty should include the drive motor (for movement) as well as the pump motor (for lifting) in the coverage plan.

Common Warranty Exclusions and Red Flags

There are always exclusions in a warranty, which mean certain items or situations for which the electric forklift manufacturer will not provide coverage. Some exclusions are normal and reasonable, but “wear and tear” dummies can be an indication of a bad product or the manufacturer’s lack of confidence in it.

Other examples of universally excluded items include electric forklift parts that are inevitably worn out as a result of use, such as tires, brake pads, fuses, and light bulbs.

Nevertheless, be cautious of warranty contracts that explicitly obscure the essence of “improper use” or “neglect” because such words can be used as a shield when unjustifiably denying claims.

- Operator Error and Neglect: The warranty does not cover any damage caused by accidents, collisions, or failure to conduct a daily inspection. In fact, it is vital to keep maintenance records since they will serve as evidence that the breakdown was not a result of neglect.

- Unapproved Modifications: Conducting modifications without the manufacturer’s consent such as installation of unauthorized attachments or tampering with the speed governor shall immediately void your entire Electric Forklift Warranty. Make sure you get manufacturer’s permission before altering your equipment.

- Use of Non-OEM Parts: Using generic replacement parts for repairs during the warranty period can be a contentious issue. While there are some laws which protect you, most manufacturers will refuse a warranty claim if they can prove that the failure was caused by a non-genuine part.

The Importance of Service Records and Maintenance

A warranty is essentially a contract between two parties: the manufacturer agrees to repair defects, and the user agrees to keep the equipment in good working condition. The top reason for warranty claim denial is the customer’s failure to follow the manufacturer’s recommended maintenance schedule.

For an Electric Forklift Warranty to stay in force, the customer should keep a comprehensive record of all service times, such as checks of fluids, watering the battery (for lead-acid), and hour meter readings.

- Scheduled PM (Preventative Maintenance): Following the 250-hour, 500-hour, and 2000-hour service intervals is must-do. Granting the manufacturer a legal loophole to deny coverage by skipping a maintenance visit.

- Certified Technicians: Lots of warranties require that repairs and major services be done by a technician who has a certification from the factory. Roles where an independent, untrained mechanic performs warranty work are usually prohibited.

- Daily Pre-Shift Inspections: Not only does OSHA insist on these, but they are also crucial for a warranty claim. Ignoring a minor issue can result in a major breakdown and the warranty may not cover the damages that the failure caused as a consequence of “continued operation with a known fault”.

Why “American Forklifts” Parts Warranties Matter?

At American Forklifts, we realize that there are times when even the best machinery ends up needing replacement parts. Thus, warranties on replacement parts become extremely important whether your original equipment warranty has already expired or a wear item needs to be replaced.

We offer some of the most transparent and robust warranties on our broad parts inventory. Aside from buying a new hydraulic pump, a replacement controller or a new set of forks, demanding the same warranty protection level for these components as for an entirely new machine is a must.

- 12-24 Month Parts Warranty: We come out for our commitments with warranties of 12 to 24 months depending on the type of part, way more than the industry norm of 3-6 months for spare parts.

- Hassle-Free Returns: We are confident about our products. In case a part doesn’t fit or fails, the warranty process will be simple and short to save you most of the time lost.

- Quality Assurance: Our parts have gone through extensive quality control assessments. This “Safety-First Promise” reassures you that the parts you install won’t void your original machine warranty and will perform as well as, or better than, the original ones.

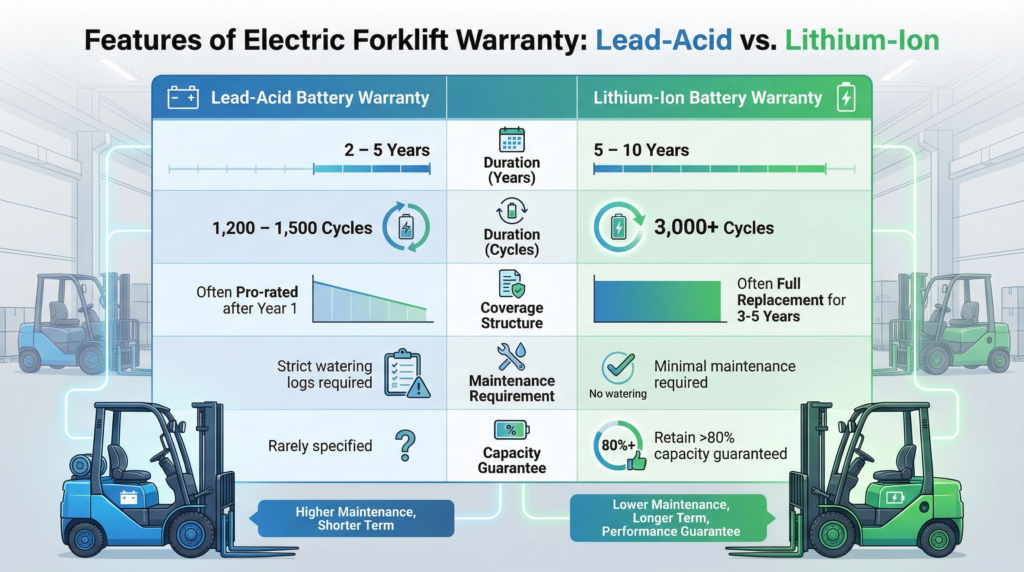

Comparison of Warranty Coverage: Lead-Acid vs. Lithium-Ion

In order to help you understand how the differences in the warranty value translate to the two battery technologies, we have created a comparison chart. It basically explains why most companies are switching to lithium-ion even though it is more expensive upfront.

Table – Features of Electric Forklift Warranty

| Feature | Lead-Acid Battery Warranty | Lithium-Ion Battery Warranty |

| Duration (Years) | 2 – 5 Years | 5 – 10 Years |

| Duration (Cycles) | 1,200 – 1,500 Cycles | 3,000+ Cycles |

| Coverage Structure | Often Pro-rated after Year 1 | often Full Replacement for 3-5 Years |

| Maintenance Requirement | Strict watering logs required | Minimal maintenance required |

| Capacity Guarantee | Rarely specified | Retain >80% capacity guaranteed |

FAQs: Electric Forklift Warranty

What is the standard warranty period for a new electric forklift?

Typically, the industry norm for a new electric forklift is a battery warranty for 12 months or 2,000 operating hours, whichever happens first. This “bumper-to-bumper” includes most major components. However, the powertrain (motors, drive axle) often has a longer warranty, e.g. 3 years or 4,000 to 6,000 hours.

Are forklift batteries covered under the standard forklift warranty?

Usually not. Industrial batteries are considered separate components, so the battery manufacturer, not the forklift manufacturer, provides their warranty. Lead-acid batteries are typically covered for 2 to 5 years, while lithium-ion batteries usually have 5 to 8 year warranties, depending on the brand.

Does an electric forklift warranty cover labor costs?

Yes, at least for the initial standard warranty period (for example, during the first year), the instruction manual usually covers the labor costs for the repair of defective parts. Travel expenses for the technician to come to your place may not be included though so always check with your policy if “travel and transport” is excluded.

Will installing aftermarket parts void my electric forklift warranty?

It’s a case of it depends. US manufacturers are prohibited from voiding your warranty solely because you have used aftermarket parts under the Magnuson-Moss Warranty Act unless your non-genuine part actually causes the failure. That being said, coverage for those particular repairs will definitely be voided if an inferior part damages the machine (e.g., a faulty controller frying the motor).

Is the warranty transferable if I sell the forklift?

Many premium electric forklift warranties can be transferred to a second owner plus this feature adds value to the equipment when reselling. Usually, there is either a transfer fee or a requirement to notify the manufacturer within a certain time period (e.g., 30 days) to keep the coverage.

What are the most common reasons a warranty claim is denied?

Denial reasons include failure to provide maintenance documentation (PM records), evidence of abuse or operator negligence (impact damage), and incorrect battery charging habits (especially for lead-acid batteries). Another denial reason that is quite common is the failure to fix minor problems which later resulted in major ones.

How do I file a warranty claim for my electric forklift?

Simply call your authorized dealer as soon as you spot a problem. Do not try to troubleshoot by yourself. Serial number, current hour meter reading, and maintenance records are some of the things you need. The dealer can then dispatch a technician to diagnose the problem and make a claim request to the manufacturer.

A Warranty To Remember: Electric Forklift Warranty

Securing the right Electric Forklift Warranty is about much more than printing out a piece of paper; it is about safeguarding your future business operational efficiency. If a manufacturer lets the product down, then the warranty is there to get your business back on track financially free from unforeseen repair costs.

The manufacturer’s confidence in their products is reflected in the warranty they provide, so it is of great benefit for you to understand the distinctions between your standard and powertrain coverage, check out warranties on batteries, and strictly follow maintenance schedules to get the maximum utility of your fleet.

To facilitate this lifecycle, American Forklifts not only supplies high-quality, warranty-backed parts, but also parts that will keep your machinery running smoothly long after the showroom warranty has expired. Put your energy into brands and dealers that are open about their products and services, read through the small print and don’t ever agree to a policy that sneaks in vulnerabilities to your vital operations.