Quite an essential investment in our days is electric forklifts for e-commerce, as they have become almost indispensable assets in modern e-commerce fulfillment centers due to their exceptional combination of sustainability, operational efficiency, and adaptability to evolving industry demands. For businesses navigating complex fulfillment challenges—where rapid order processing, environmental responsibility, and precise material handling are essential—investing in the right electric forklift is crucial.

Through this article, we aim to offer a comprehensive, capacity and speed requirements data-based, exploration, and specially suitable for electric forklifts for e-commerce fulfillment centers, the electric forklifts are the right ones. Besides data and research-based findings, the blog also provides the reader with the necessary knowledge for putting into practice the utilization of fleet operations and, consequently, gain a competitive advantage in the logistics sector of e-commerce which is characterized by being rapid.

Rise of Electric Forklifts for E-Commerce Fulfillment

Electric Forklifts for E-Commerce fulfilment centers are facing dramatic shifts in logistics expectations and sustainability mandates, making electric forklifts a critical choice in optimizing productivity and environmental stewardship. As market trends push toward rapid, agile warehousing solutions, operators require machinery that not only maximizes throughput but also delivers clean and quiet operation suitable for densely populated workspaces.

- What we essentially get is the requirement for swift, yet sustainable and practical solutions, a perfect fit for electric forklifts as they can bring down environmental and noise pollution levels to a great extent while also maintaining quality performance.

- The electric forklifts are perfect for the implementation of electric forklifts for e-commerce centers since they can easily meet the standards of air quality restrictions indoors, reduce the operation noise, and provide a steady load-bearing function.

- To be sustainable in e-commerce logistics is the main goal and electric forklifts are a very powerful tool to reach it as these forklifts produce no emissions locally and help companies lower their carbon footprint significantly.

- In a warehouse where many picks are done, silence and low vibration of electric forklifts contribute to the safety of the environment as it becomes a less stressful place to work.

- Government rebates and environmental awards are among the reasons why electric e-commerce freight companies find it easier to make the decision and accept the electric solutions.

The fact that the electric forklifts are in line with the industrial revolution, which is the consumer demand-led, fast fulfillment cycles, and global environmental goals, makes them the building blocks of the future in the online retail material handling arena.

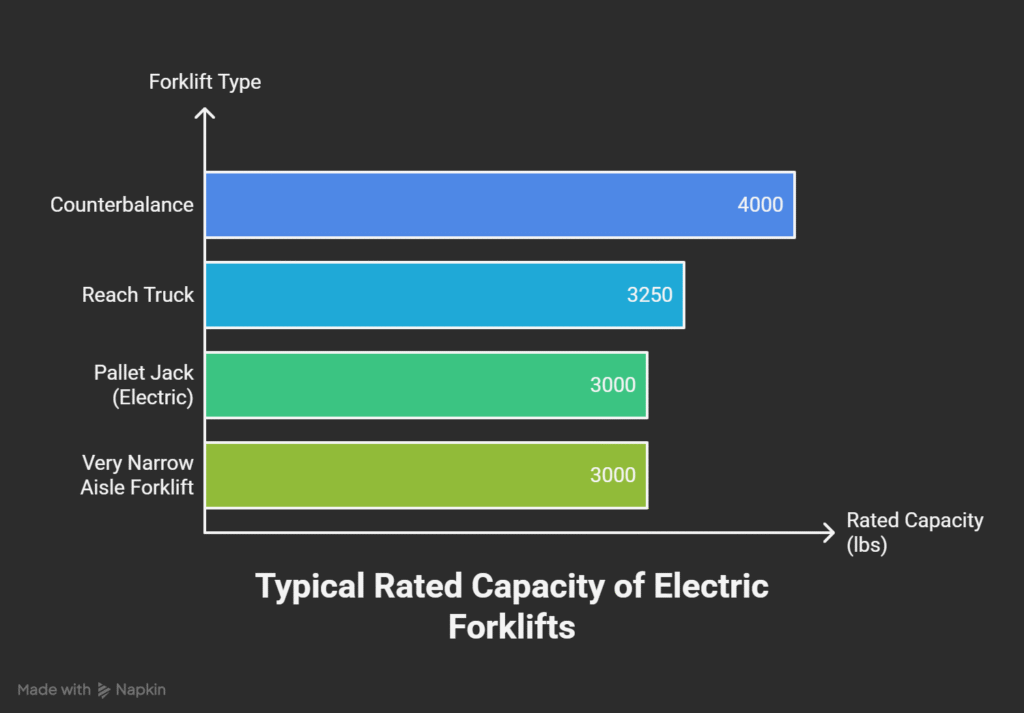

Core Capacity Requirements for E-Commerce Fulfillment Forklifts

The most effective way of matching electric forklift capacity to the actual workload is by the procedure of estimating and removing ‘the bottlenecks of production in the operational processes of the enterprise.’ An electric forklifts for e-commerce fulfillment center usually deals with a mixed assortment of products, which would lead to it having different issues.

- The problems that the center would face are the capacity of the lifting and load stability aspects of the product. The consequences of not using the right forklift class are machine strain, more periods of equipment downtime, and even occurrences of safety violations.

- In most cases, the weight of the shipments done in the fulfillment centers will be within the range of 2,000-5,000 lbs. It is also a good thing that the electric forklifts can be equipped with configurations that allow the carriage and forks to be adjusted, so they can excel in scenarios where there are mixed products.

- In a average warehouse, it is common that the racks are higher than 25 feet; thus, the only proper way to reach and work on the shelves at such height is by using the mid-to-high capacity electric reach trucks or a counterbalance forklift with extended mast as the vertical part.

To make efficiency levels reach their maximum potential, it is a good idea to consider the rated capacity of a forklift at various heights of lifting for some models, at full extension, the rated capacity significantly drops, and this can affect the speed of order picking and thus the flow of work.

Capacity Table: Popular Electric Forklift Classes for E-Commerce

| Forklift Type | Typical Rated Capacity (lbs) | Max Lift Height (ft) | Common Warehouse Use |

| Counterbalance | 3,000–5,000 | 15–25 americanforklifts | Pallet transport, dock loading |

| Reach Truck | 2,000–4,500 | 20–35 americanforklifts | Narrow aisle storage, order picking |

| Pallet Jack (Electric) | 2,000–4,000 | 7–9 americanforklifts | Low-level picking, short-range moving |

| Very Narrow Aisle Forklift | 2,500–3,500 | 40+ americanforklifts | High-density racking, minimal aisles |

The appropriate electric forklift capacity selection will not only enable the operators to deal with the surge in order volumes but also with the usual daily inventory movements without facing any equipment limitations or workflow delays as well.

Speed Requirements for High-Throughput Fulfillment

If we talk about an e-commerce, it will be a fulfillment center, and the question, how quickly the materials are moved, is directly related to through put and the satisfaction of customers. When the work conditions in which are set to be the best, the electric forklifts will be able to perform, without making the whole process slow, the time-critical workflows, such as receiving, put-away, picking, and shipping.

The running of multiple shifts and the managing of seasonal spikes cannot be done successfully unless the performance metrics of the forklifts are carefully analyzed.

As one of the best electric fork with leading features models can make the highest speed of travel be at 6–10 mph, which is a very good combination of fast operation and strict safety standards for indoor environments.

The speed of lift is the rate at which the fork has its load raised vertically and most premium pieces of equipment reach this speed of 90–140 ft/min, which also makes the access to goods stored at different heights quite fast.

Moreover, speed requirements should also be accompanied by considerations about the maneuverability. In fact, electric forklifts designed for the operation in a tight aisle or in a congested area usually come with a responsive steering and a compact chassis that both maximize speed and safety because of that.

Technical Innovations Driving Electric Forklift Performance

One cannot overlook the role of technology in shaping the design of electric forklifts, resulting in a considerable leap forward in the achievement of precision in operations, efficiency, and safety in e-commerce fulfillment centers.

The manufacturers and the research organizations that are at the forefront of the industry keep on making improvements in the battery systems, the ergonomic controls, and the connectivity features, all of which are direct contributors to the strength of the material handling in the complicated warehouse settings.

The transition to the use of lithium-ion batteries is accompanied by the fact that they permit fast charging (1–2 hours) and have a long life when compared with the traditional lead-acid systems.

Through the use of telematics integrated in different equipment, the performance, location, and maintenance needs of a forklift are monitored in real-time which leads to a reduction of unplanned downtimes and better fleet utilization.

The production of productive and safe workers has been contributed to by the presence in the workplace of operator cabins that are ergonomically designed, intuitive control interfaces, and the implementation of safety mechanisms.

Such innovations are the reason why fulfillment centers can keep the throughput at the same level even with the long hours of work, reduce the routine maintenance that has been made easier by the use of sophisticated technology, and create a culture of safety and continuous-upgrade in the workplace.

Choosing the Right Electric Forklift Model

What e-commerce fulfillment calls for is the right selection of an electric forklift, and there are hundreds of models of it available in the U.S. market. There is no better way than doing it by first making a thorough and complete evaluation of operational needs based on results and vendor offerings. The most crucial factors are lifting height, rated capacity, aisle dimensions, battery technology, and the safety features that can be made available.

Counterbalance electric forklifts are the ones that cover the widest range of needs and can be used both inside and outside for the handling of materials. These are the most suitable for work with both mixed inventories and different types of industrial enterprises.

The narrow aisle reach trucks are the storage capacity maximizers since they allow the operation of the racks that are high density. Thus, they are perfect for those fulfillment centers that put the vertical utilization as a priority.

Electric pallet jacks are the ones that no warehouse can do without when doing picking at low levels and when the goods need to be moved quickly at the loading dock, packing station, and the staging area.

Working hand in hand with a trusted forklift dealer and looking into unbiased reviews from American Forklifts which provides you with up-to-date information on the topic, expert knowledge, and the option of trial, you also get the most transparent evaluations of total cost of ownership and long-term support made available.

Safety in High-Speed: Electric Forklifts For E-Commerce Centers

The problem with safety when the electric forklifts are being driven at high speeds in a busy fulfillment center is that, it is the thing that comes at the very forefront of the priorities of the organization. The managers and the operators are the ones who must see that the installations for the inspections are done. Apart from that, they have to apply in every operational procedure strictly, and also put to use the advanced safety concept so that an equipment failure or an accident in a workplace can be averted.

Inspection of safety on a daily basis—among which the checks of brakes, steering, mast operation, and battery integrity are the most important—are a requisite to the safe performance of the machine.

The systems of avoiding collisions, the sensors that detect the presence of an operator, and alarms of getting close to an object work together to make sure that accidents are far from happening in places where there is high population like a warehouse.

By developing and incorporating a philosophy of safety as an extremely important aspect and utilizing smart technologies, centers that are into fulfillment can increase the feeling of security among workers, reduce the risk of being held liable, and at the same time meet the highest standards of operations in the industry.

Maintenance and Longevity for Electric Forklifts in Fulfillment Operations

To ensure that electric forklifts for e-commerce remain reliable and live a long life in the demanding environment of e-commerce, a maintenance plan of a strategic nature that is focused on technical and proactive care needs to be drawn up.

Regular upkeep reduces forced downtimes, extends the life of the devices, and assures that the standards set by the manufacturers and the regulations will continue to be met.

In the case where the power unit for the electric fork is composed of AC motors, then it is certain that the unit will have less maintenance requirements due to the fact that it has fewer moving parts and the management of the heat is better so the mechanical failure rate is also lower.

Regularly scheduled software updates and telematics reporting activities that also serve as diagnostic tools keep the managers informed well in advance of any issues that can become obstacles for the workers’ main operations. Consequently, they provide ample time for quick maintenance responses.

Manufacturers’ support services and the availability of more extended warranty plans are more than recommended in the case of fulfillment centers where heavy usage is the case and there are shipping commitments for which time is of essence.

Sustainability and Green Logistics in E-Commerce Fulfillment

A fulfillment center becomes even more attractive to the green logistics sector and creates a competitive advantage for itself in a market where more and more climate-aware businesses are positioning themselves by simply adopting the use of electric forklifts.

FAQs: Electric Forklifts for E-Commerce Fulfillment Centers

What is the capacity for my electric forklifts for e-commerce material handling?

The majority of the fulfillment centers would most likely require forklifts with capacities that range from 2,500 to 5,000 lbs so that they can handle product portfolios in a way that is effective and efficient.

How do electric forklifts for e-commerce improve speed of fulfillment operations?

The electric forklifts are the ones that deliver travel speeds of up to 10 mph and fast lift cycles which make it possible for rapid receiving, put-away, picking, and shipping of orders to be carried out.

Are electric forklifts suitable for multi-shift and 24/7 operations?

The few models that come equipped with lithium-ion batteries, in which energy can be restored quickly and the runtime is long, make it possible for a standby time that is very short or even no standby time at all between continuously repeated multi-shift activities so that the latter can be carried out smoothly,

What safety features should be prioritized for busy fulfillment centers?

You can have collision avoidance systems, operator presence sensors, and daily safety checklists to help you ensure that employees are kept safe at the workplace.

How do electric forklifts for e-commerce contribute to sustainability goals?

Electric machinery that gets rid of local emissions, reduces energy use, and battery recycling supports is what you find at the forefront of green logistics programs that are the most ambitious about the climate.

What maintenance schedules are recommended for electric forklifts I fulfillment centers?

Some of the key practices in which the maximum reliability and long life can be achieved include the injections of professional inspections all carried out once every three months, daily checkups before operating, and the use of onboard telematics.

Are there incentives for switching to electric forklifts for e-commerce operations?

The incentives are hardly ever absent in the case of the switching to electric forklifts in e-commerce operations. They usually come in the form of government rebates, sustainability certifications, and good brand reputation.

Final Share: Electric Forklifts for E-Commerce

The leading position of the electric forklifts for e-commerce in this modern age of digital shopping in the fulfillment centers is a fact that cannot be debated. They are still the powerful solutions that every capacity, speed, safety, and sustainability need in the digital era among electric forklifts for e-commerce.

The businesses can by adopting the best practices of the industry, applying the most rigorous evaluation methods, and relying on the impartial and professional insights of American Forklifts, confidently select, implement, and manage a fleet of electric forklifts that are designed for the highest echelon of fulfillment operations.

Consequently, it is a win-win situation for the electric forklifts for e-commerce fulfilment centers becoming more efficient while at the same time lessening their impact on the environment and having a solid footing for ensuring that in the midst of such ever-changing logistics world, their growth will be there.