Industrial businesses nowadays are moving at such a pace that they are always on the lookout for new and clever solutions not only for productivity shooting but also for a competitive advantage among the forklift attachments.

Concerning the material handling sector, forklift attachments are the innovations that are slowly yet surely revolutionizing warehouse operations worldwide. If you are still using just the basic forks, then you are missing out on tools that can reduce your organization’s downtime to such an extent that safety and ROI will be enhanced besides.

Material handling has entered a different dimension nowadays where a single forklift attachment is not only a support for your work but also a complete change of it. Here we are going to talk about the game-changing forklift attachments that your competitors are either using or wishing that they had.

Why Forklift Attachments Are a Game Changer

Stages in history are not what distinguish forks but the company they come with. Forklifts in reality which are equipped with attachments form the perfect synergy for the said vehicle to chauffeurs—the additional equipment expands the usage of the forklift up to extremely doing just easy but effective task like pallet lifting and transportation only. The good thing with a right type of attachment is that you can show off your business running steadily in a very good way while customer caring at the same time.

Benefits Include:

Enhanced Efficiency: By simply implementing the task with mechanical mastering in the direct way as instructed shall lead the contractor to save the half of the time he would spend if he were to do the same task manually.

Improved Safety: The utilization of attachments especially renowned for high safety standards remarkably contributes to this.

Cost-Effectiveness: Wide enough range of machines and yet, diverse enough types of products ensure many special conditions in public and private logistics services which might have been taken by one company only using a multifunctional machine without buying the other one for a different task.

| Benefit | Impact Area | Result |

| Time Savings | Operational Workflow | Increased throughput |

| Safety Enhancements | Compliance & Liability | Reduced injury claims |

| Versatility | Equipment Investment ROI | Less need for multiple machines |

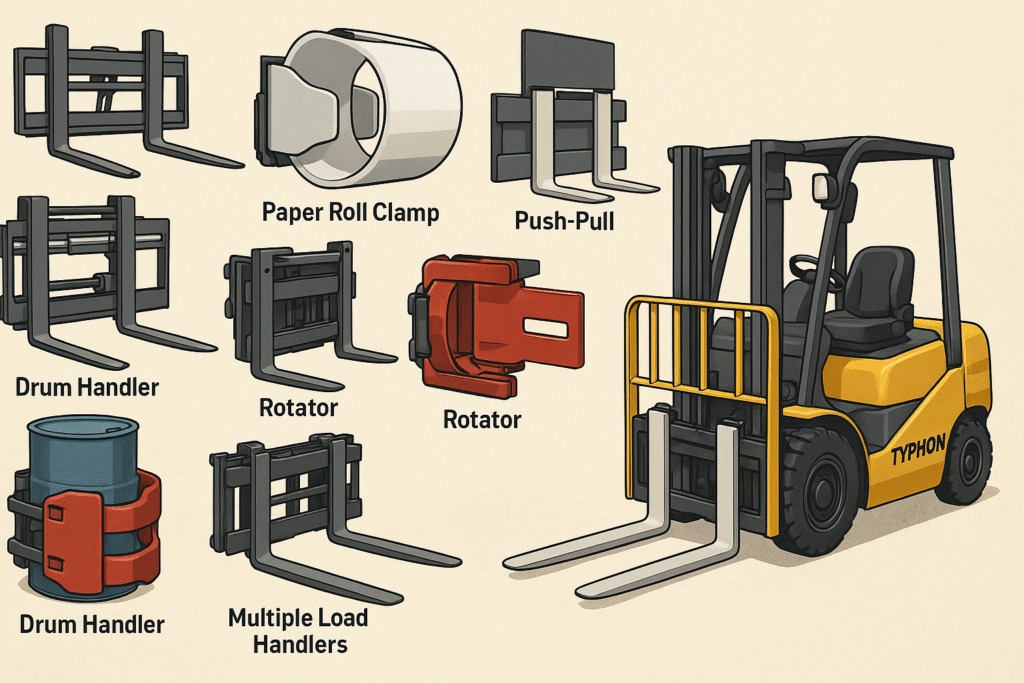

The Top 7 Forklift Attachment Types List:

1. Side Shifters: The Unsung Hero of Speed

One lateral movement device allows an operator to move a load to the left or to the right without moving the whole forklift. It is adapted for short pallet adjustment or for adjusting loads that are inside a small space in the rack.

Key Factors:

- Quick Load Positioning: Save double-digit seconds for every picking and dropping.

- Lowered Forklift Movement: Along with tire and fuel wear reduction.

- Better Pallet Placement Accuracy: In narrow aisles or tightly packed warehouses this could be a real game-changer.

2. Fork Positioners: No More Manual Adjustments

An ideal setup for a warehouse with different sizes of pallets, fork positioners let the operator hydraulically adjust the space between the forks.

Prominent Usage Factors:

Expression of the main reasons for use:

- Makes It Possible to Handle Mixed Pallet Sizes: Removal and manual repositioning of forks is not necessary anymore.

- Decreases Operator Fatigue: Only the cabin is equipped with the control devices.

- Loading Operations Get Faster: Every time an adjustment is made, time is saved.

3. Paper Roll Clamps: a Must-Have for the Paper and Packaging Industry

Just like in paper manufacturing or paper packaging, Roll Clamps offer a method that is both safe and practical to carry cylindrical loads without damaging them.

Why They’re Essential:

- Damage-Free Handling: The padded clamping prevents the tearing or deformation of the product.

- Secure Rotation: You can rotate the rolls 360° to get exact positioning.

- Single Operator Control: No requirement for additional handlers.

4. Push-Pull Attachments: See the End of Pallets

Are you willing to cut pallet costs and the shipping weight? Push-pull attachments are made to take off slip-sheeted loads, thus there is no need for wooden pallets.

Key Benefits:

- Pallet-Free Shipping: Costs are lowered and the environmental impact is reduced.

- Maximize Load Space: You can put more products in the same truck or container.

- Great for Export: No pallet fumigation is required for the overseas shipping.

5. Rotators: Flip It Without the Hassle

Forklift rotators give you the power to turn the carriage 360 degrees. This is a great help in food processing, waste handling, or manufacturing – the times when dumping or turning loads are necessary.

Major Advantages:

- Improved Dumping Control: The food, waste, and recycling industries are the major areas where this can be best applied.

- Non-Uniform Loads are Handled: You can fill or reposition containers that are emptying only a little with the help of this device.

- Time Saver: A single-step load rotation takes only half the time needed for manual work and, thus, saves labor.

6. Drum Handlers: Manage Hazardous Materials Safely

Drums are tough to lift with standard forks, and that’s why drum handlers basically make the whole thing easy, safe, and in line with OSHA regulations.

Why It Matters:

- Safe Hazardous Material Handling: Limits spills and pollution risks.

- Helps All Drum Types: Plastic, paper, and metal.

- One-Person Operation: No more difficult two-person handling.

7. Multiple Load Handlers: Do More with One Lift

Why first lift one pallet just to move the other two, four, or even six? Multiple load handlers are an ideal solution for a branch with a high volume of daily trading / distribution.

Core Benefits:

- Double or Triple Productivity: Get the palletizing done faster with less ground work (trips).

- Efficient Warehouse Utilization: More flow is possible without the congestion of standard aisles.

- Scalable Options: Select 2, 4, or more forks based on your warehouse layout and needs.

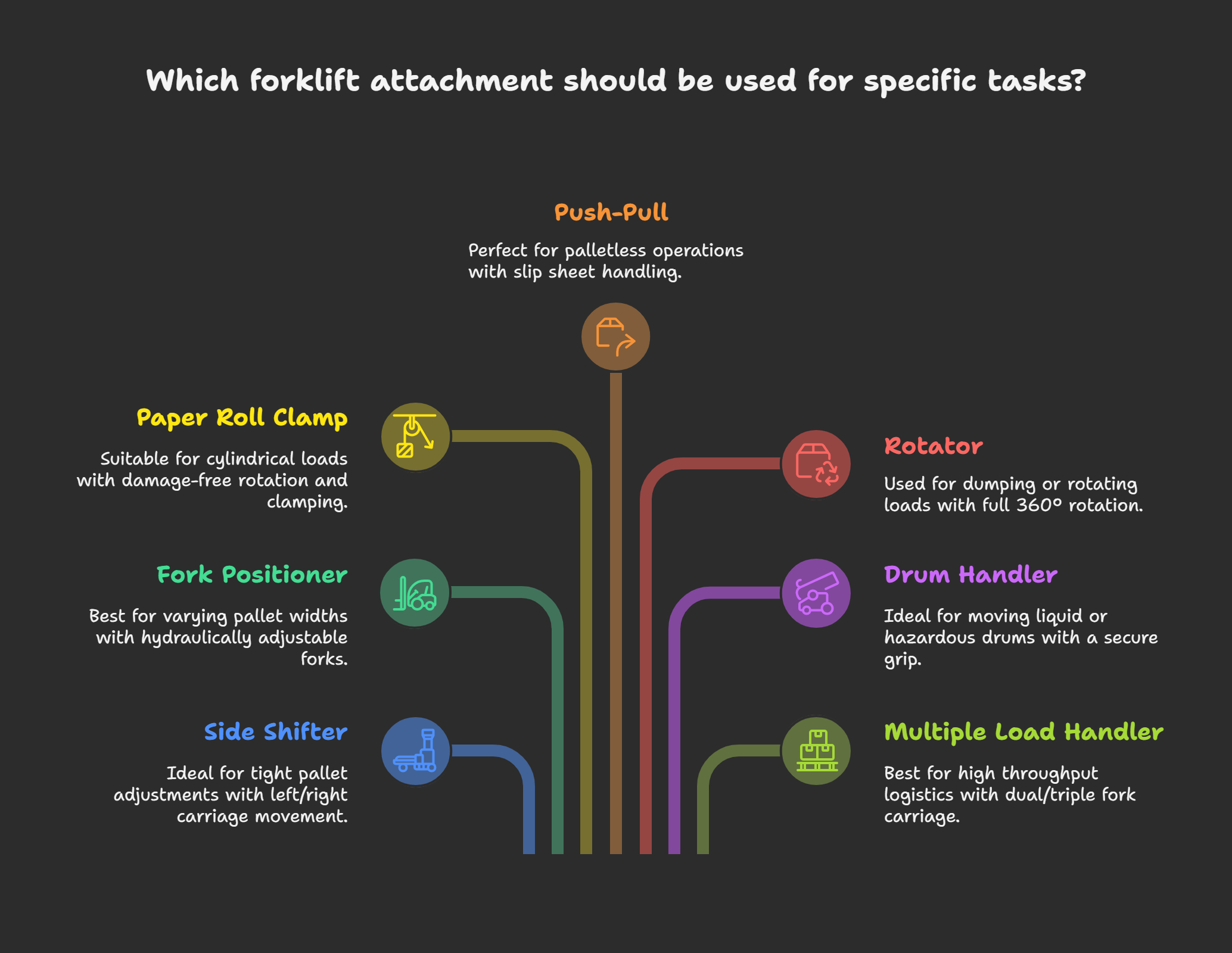

Choosing the Right Forklift Attachment: A Quick Comparison Table

| Attachment Name | Best For | Key Feature |

| Side Shifter | Tight pallet adjustments | Left/right carriage movement |

| Fork Positioner | Varying pallet widths | Hydraulically adjustable forks |

| Paper Roll Clamp | Cylindrical loads | Damage-free rotation and clamping |

| Push-Pull | Palletless operations | Slip sheet handling |

| Rotator | Dumping or rotating loads | Full 360° rotation |

| Drum Handler | Liquid or hazardous drum moving | Secure grip on round drums |

| Multiple Load Handler | High throughput logistics | Dual/triple fork carriage |

Key Factors to Consider Before Buying Forklift Attachments

Before making an investment, be sure to think about these basics:

Things to Keep in Mind:

- Hydraulic Compatibility: Your forklift must support hydraulic controls for most attachments.

- Weight Capacity Adjustments: Attachments add weight, reducing lift capacity.

- Operator Training: Specialized gear requires trained personnel.

Pro tip: Always consult the manufacturer or a certified forklift technician before retrofitting your existing machine.

How Forklift Attachments Impact ROI

Excepting the right attachments can make a powerful ROI within a very short time, mostly by reducing labor, proper care of the product, and, finally, increasing safety. Here is a very simple ROI view:

| Metric | Without Attachments | With Attachments |

| Pallets moved/hour | 40 | 70 |

| Man-hours required/day | 8 | 5 |

| Average damage/month | $500 | $150 |

| Operational efficiency | Moderate | High |

Final Thoughts: Don’t Let Your Competitors Get Ahead

Forklift attachments are no longer optional. They’re an investment in speed, safety, and scalability. Businesses leveraging these tools are reaping measurable gains in efficiency and profitability — and so can you.

If you are in retail, manufacturing, shipping, or agriculture, the solution can be found in one of the many attachments, which allow workers to complete their tasks in a more efficient, safe and cost-effective manner.

Take action today. Reach out to us for the guidance of an expert and find out the ideal forklift attachment that will be able to lift up your works.

FAQs About Forklift Attachments

What is the most commonly used forklift attachment?

The side shifter is the most typical one that it is the most broadly used on account of its widespread application in warehouses and loading docks.

Are forklift attachments interchangeable across all forklift brands?

Not always. You have to ensure that the hydraulic compatibility and the mounting style match your specific forklift model.

Do attachments affect a forklift’s weight capacity?

Indeed. The attachments add up with the weight carried on the carriage and thus reduce the total lifting capacity of the machine. The data plate ought to be checked every time.

Can I install forklift attachments myself?

Just a few of the basic ones may be done manually by using some simple hand tools, but in general, hydraulic attachments require a technician to do the proper setup.

How do I maintain these attachments?

Regular greasing, hydraulic inspection, and cleaning are essential. Most attachments have the manual as their guide for the service intervals.

Are these attachments OSHA-compliant?

Yes, if they are correctly installed and the operators are well-trained. The users, during the operation, should always follow the OSHA installation guidelines.

Where can I buy high-quality forklift attachments in the U.S.?

Visit americanforklifts.org to view great options for the reliable and certified attachment suitable for all industries.