Choosing the most suitable battery type is one critical decision that stands out when it comes to powering electric forklifts in today’s fast-paced warehouses and logistics centers. The argument to choose between lithium-ion vs lead-acid forklift batteries as one type of battery over the other has been pivotal in the transition of modern forklift fleets as well as in the change of operational strategies of American businesses.

This is a point that American Forklifts, who have a vast knowledge of all the aspects of forklift technology, make very clear among the difference between lithium-ion vs lead-acid forklift batteries. Balancing performance, efficiency, sustainability and long-term costs are now more important for companies that want to have a competitive advantage in 2025.

In effect, this all-encompassing guide is one that goes through every main difference, benefit, drawback, and practicality to provide the managers, buyers, and operators with the most comprehensive understanding possible.

Understanding Battery Technologies

Lithium-ion vs Lead-acid Forklift Batteries:

Two drastically different kinds of battery technologies-electric (liquid) lead-acid and advanced lithium-ion are the basis of power for electric forklifts. Both have different features, maintenance necessities, and prices.

While lead-acid batteries have been used for years in the market and have been reliable in heavy-duty environments, they still require the user to maintain them, follow these charging routines and even change them from time to time.

On the other hand, lithium-ion batteries are the epitome of a modern technology solution where faster charging, longer lives, and no maintenance necessities are part of the technical characteristics which quickly attract progressive fleet owners and green-conscious enterprises.

Considerations for the selection of the battery type would help to maximize operating durations, decrease expenses, and smooth the warehousing productivity index.

For comparison purposes, both technologies are imperative for decision-makers/co-founders especially when they intend to make their stock of capital a future-proof investment and maximize return on it. Next, we’ll examine the features that differentiate lithium-ion from lead-acid batteries.

Performance and Efficiency Comparison Between Lithium-ion vs Lead-acid Forklift Batteries:

The type of battery has a decisive say in the performance of forklift operations. Power availability to the number of cycles even to the cycle life all kinds of battery show their effects visibly on the profitability of the worksites and on the cost of work.

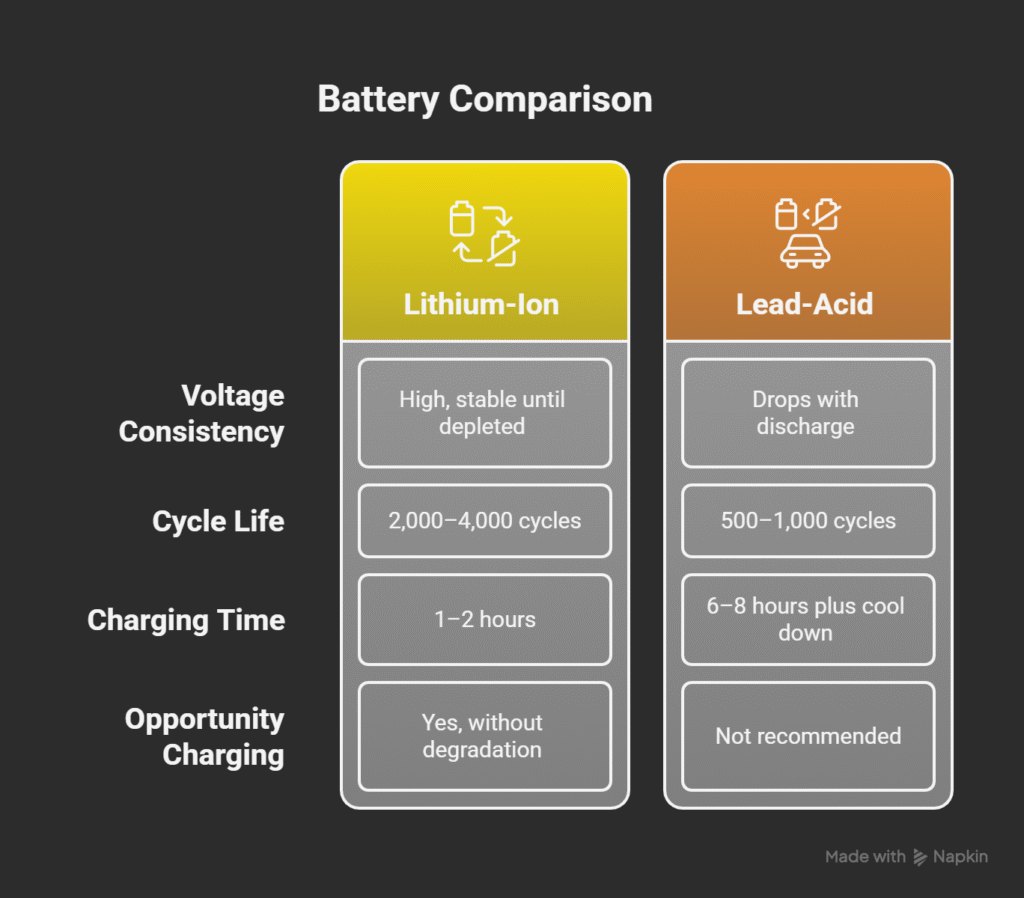

- Operating Voltage Stability: One of the main points is that lithium-ion batteries keep their voltage at a certain level so that the forklifts will work at their highest capabilities throughout the cycle; on the contrary, lead-acid batteries are generally lower in voltage as their charge gets to the end, which can cause slow and efficiency loss of a forklift in lifting tasks.

- Cycle Life: The standard number of lifecycle Lithium-ion batteries are quoted to 2000-4000 recharge cycles whereas the lifecycle of lead-acid batteries is limited to less than a thousand cycles, a battery loses its capacity severely at one thousandth of recharge cycles. As a consequence, this means that there will be longer service intervals and more lithium-ion batteries can be used in place of one lead-acid battery for replacement purposes.

- Quick and Opportunity Charging: The process of recharging lithium-ion batteries takes significantly less time than that for lead-acid batteries, usually less than two hours, and they also have the option to accept frequent “top-off” charges. Lead-acid batteries can be recharged only through the completion of their cycles, and additionally, there is a phase of “cooling down” which quite limits their flexibility when it comes to multi-shift operations.

| Feature | Lithium-Ion Batteries | Lead-Acid Batteries |

| Voltage Consistency | High, stable until depleted | Drops with discharge |

| Cycle Life | 2,000–4,000 cycles | 500–1,000 cycles |

| Charging Time | 1–2 hours | 6–8 hours plus cool down |

| Opportunity Charging | Yes, without degradation | Not recommended |

By the use of lithium-ion batteries, companies are enabled to prolong usability, strengthen operational effectiveness, and lessen the chances of encountering the situations of unplanned downtime. Their endurance against high-frequency usage turns them into the most alluring ones for the logistics hubs with high demands as well as for around-the-clock operations.

Maintenance, Safety, and Longevity: Lithium-Ion Vs Lead-Acid Forklift Batteries

It is not only the money but the time and resources that are used for battery maintenance which can have a significant impact on reliability and on the overall running costs for a fleet manager.

- Maintenance Demands: Due to the risk of acid spills and hydrogen gas emission lead-acid batteries require frequent water additions, equalization, cleaning, and ventilation. These maintenance tasks use workers’ time and this causes an interruption of the workflow.

- Lithium-Ion Simplicity: The different unit is lithium-ion batteries which are sealed units, need no watering, cleaning, or ventilation, and are free from the risk of corrosion and spillage. This equals lower staffing requirements as well as traffic of health and safety regulations.

- Life and Guarantee: Most lithium-ion batteries are equipped with 5+ year warranties and are used for up to eight years depending on how they are used, whereas, lead-acid batteries are changed around every 2-3 years. Reduced number of replacements diminishes lifecycle costs and creates longer periods when the forklifts are on duty rather than waiting for the repair.

In the first place, safety is of utmost importance, nevertheless, lithium-ion batteries have mechanisms that prevent overheat, excess charging and deep discharge, hence they are the safest when used in closed spaces and indoors.

Cost Considerations and Return on Investment (ROI)

While planning a budget for forklift batteries between the lithium-ion vs lead-acid forklift batteries, one should not overlook the recurring nature of both initial and ongoing costs. Businesses often assess the initial investment against the savings generated during the overall service life of the equipment.

- Upfront Cost: Lead-acid batteries are less expensive at the point of purchase, which is very appealing for those with limited budgets. However, this usually results in higher long-term costs because of frequent replacements and more considerable maintenance investments.

- Total Cost of Ownership: The price of lithium-ion batteries at the point of purchase is 2–4 times higher than that of lead-acid batteries but they pay back this money with savings in labor, charging time, utility bills and life spans. Total costs for lithium-ion are usually lower than those for lead-acid when all the cost factors and labor are taken into consideration for a period of five years or more.

- Energy Efficiency: One of the main reasons why lithium-ion battery technologies are better than lead-acid is the fact that they can convert more of the electricity that is put into them into usable power. Therefore, operating costs in terms of utilities can be diminished by up to 30% compared to lead-acid models that are used for the same number of shifts with identical workloads.

- Residual Value: When batteries reach the end of their lifespan, lithium-ion ones in most cases may still have a significant amount of value for recycling and repurposing which can facilitate the replacement costs.

Table: Cost Factors of Lithium-Ion Vs Lead-Acid Forklift Batteries

| Cost Factor | Lithium-Ion | Lead-Acid |

| Initial Price | Higher | Lower |

| Replacement Frequency | Rare (every 5–8 years) | Frequent (every 2–3 years) |

| Maintenance | Minimal | High |

| Energy Efficiency | Superior | Less efficient |

| Lifetime Cost | Lower over time | Higher over time |

Frequent are the reasons that managers, who do not take into consideration sticker prices only, get back their lithium-ion battery investments in a number of ways: longer maintenance intervals, labor reduction, and productivity increase.

Environmental Impact and Regulatory Compliance

One of the most dynamic changes in the North American material handling and logistics firms’ concerns list is that sustainability is now ranked as a top concern. Apart from it, the major manufacturers of the products take a special look at the environmental profiles of forklifts and other supporting equipment.

Environmental Impact of Lithium-Ion Vs Lead-Acid Forklift Batteries:

- Lead-acid Batteries: The whole life cycle – from the manufacturing stage to maintenance and disposal – raises the chances to expose the environment and people to toxic chemicals, heavy metals, and airborne electrolytes. While there is safe recycling, it can be costly, and if recycling is not done properly, it can result in environmental pollution and non-compliance with EPA regulations.

- Lithium-ion Batteries: The production of lithium-ion batteries is much cleaner, and the emission is lower, particularly for a unit with advanced cell chemistries. Those batteries that are expired are not charged if they are going to be recycled in the specicized places. Their long life reduces total hazardous waste disposal and increases a company’s sustainability scores.

- Efficiency and Green Credentials: The use of lithium-ion batteries in forklift fleets can draw benefits from green incentives, rebates, and local tax credits that are usually associated with energy efficiency and worker safety. And this can make the costs go down directly and increase brand reputation among customers and other stakeholders who are eco-conscious.

Sustainability is not only about passing the environmental regulations; companies that use lithium-ion batteries for their forklifts can also feel the benefits in their smooth regulatory inspections and better public relations.

Practical Fleet Management Considerations

The best use of electric forklift batteries is highly dependent on the operating environment, shift length, warehouse layout, and temperature variations.

- Multi-Shift Operations: The use of lithium-ion batteries can be very beneficial in a situation of multi-shift operations where they are required to be recharged in a very short time and forklifts can work almost continuously. The charging that is done during breaks or lunch can keep the fleet moving without having back-up batteries.

- Space Optimization: The charging locations for lead-acid batteries are usually in separate rooms with ventilation systems because of the emissions of hydrogen and the risk of acid spills. On the other hand, the charging stations for lithium-ion batteries can be located anywhere in the warehouse and thus the space can be used for either merchandise or racking.

- Extreme Conditions: It is not uncommon to find that advanced lithium-ion batteries are able to endure the changes in temperature well and on top of that, they can also work in a refrigerated storage or a hot outdoor site without fail. In the case of lead-acid, if there is a temperature variation, the capacity and charge acceptance will decrease significantly and thus there is a possibility of downtime or performance that is less than expected.

Along with brands, a business that deals in many different kinds of fork lifts and attachments will have to be compatible and interchangeable to be able to easily change over to lithium-ion batteries as they are made in modular designs and can be integrated with various makes and models, thereby simplifying fleet expansion and upgrades among batteries between lithium-ion vs lead-acid forklift batteries.

Technology Trends and Innovations

The changes in the forklift industry are fast and the cell phone makers are already launching the smart battery solutions for the future warehouses.

- Smart Battery Management: The lithium-ion batteries provide the users with real-time information about the state of charge, usage pattern, and upcoming maintenance by installing diagnostics that can predict when the maintenance will be needed.

- Ergonomics and Operator Safety: The lithium-ion batteries that are lighter enable the driver of the forklift to be more comfortable by the fact that it reduces the overall weight of the forklift and the optimal weight distribution which in turn helps the machine’s life to be prolonged and the operator to be protected from the continuous use of the same muscles which leads to the repetition of the strain injury of bones and muscles.

- Integration with Warehouse Automation: The lithium-ion batteries that are fast charging and with flexible recharge options perfectly fit the automated guided vehicles (AGVs), robotic lift trucks, and other new material handling technologies.

- IoT and Connectivity: Some lithium-ion batteries have direct connections to fleet management platforms, giving managers easy access to usage tracking, preventive maintenance scheduling, and energy consumption optimization. This technology facilitates operations by cutting down on lost time and increasing asset productivity.

By keeping up with changing trends, buyers and operators are positioned to make investments that deliver benefits now and retain value deep into the future. American Forklifts’ blog is a leading resource for tracking battery innovations and related forklift tech among Lithium-Ion Vs Lead-Acid Forklift Batteries .

Decision-Making Guide: Which Is Right for Your Fleet?

The best decision to choose between Lithium-Ion Vs Lead-Acid Forklift Batteries comes down to the business needs, size, and long-term plans. Here are some points to support decision-making:

- Lead-acid batteries are budget-friendly if the price is the main concern, however, they involve higher maintenance and a shorter life span.

- For companies that are focused on productivity, the lowest possible downtime, and lower life cycle ownership costs, the use of lithium-ion batteries will result in such a situation which is almost impossible to be surpassed and that is why they are called game changers.

- Besides that, the ecological aspects of the business, ease in complying with the regulations of the workplace, and the safety of the working environment are the factors that are leading companies into choosing lithium-ion technologies.

It is advised to consider bulk purchase discounts, compatibility with current forklift models, warehouse downtime policies, and access to service/support networks prior to a technology switch. For very detailed reviews, completely fair comparisons, and purely expert opinions fitting to the most severe operational challenges of today, consult resources like American Forklifts.

FAQs: Lithium-Ion Vs Lead-Acid Forklift Batteries

How long are lithium-ion forklift batteries built to last compared to those of lead-acid?

Lithium-ion batteries have a life span of around 5 – 8 years (2,000 – 4,000 cycles), thus are much more long-lasting than lead-acid batteries which typically function for 2 – 3 years (500 – 1,000 cycles).

Are lithium-ion batteries compatible with all forklift models?

Most of the major manufacturers provide modular lithium-ion batteries that are compatible with the major kinds of forklifts, however, it is always recommended to first confirm with your forklift supplier whether it is appropriate for your model.

Is it true that lithium-ion batteries are very efficient in energy saving?

Yes, these types of batteries are made 30% more energy efficient than lead-acid ones and thus they cut electricity use and reduce utility bills in the whole operational cycle significantly.

Are lithium-ion batteries considered safe when used indoors?

Without a doubt – they are sealed, don’t release any harmful gases, and have on-board safety features for maximum security. Lead-acid batteries may become a danger source resulting from gas emissions and spillages in the enclosed space.

What maintenance work will be required of lithium-ion forklift batteries?

None of these batteries is a sealed unit, where there is no need for watering or cleaning, thus less maintenance work is performed, and the risk of stopping due to the lack of a part is lowered.

Which battery type leaves the least carbon footprint?

The environmental impact of lithium-ion batteries is near zero as a result of cleaner operation, longer life, and recycling opportunities for them as compared to lead-acid ones.

How does the cost of lithium-ion batteries compare with those of lead-acid over time?

Although pricier in the beginning, lithium-ion batteries make it up during their life cycle with fewer replacements, lower maintenance, and energy-saving which results in a lower total cost per operating hour.

Choose Wisely – Lithium-Ion Vs Lead-Acid Forklift Batteries:

As the developments of battery technology keep on progressing and the speed of adoption continues, American Forklifts will be there to provide the most thorough and impartial guidance to those who consider investing in next-generation forklift solutions.

For the latest updates, expert tips, product reviews, and the newest advances in forklift battery technology, kind visit americanforklifts.org. Your right battery choice could be the one that takes your business to heights never seen before — providing efficiency, profitability, and sustainability for the years to come.