Forklifts are an essential component of many large-scale operations, making life easier for manufacturers and workers worldwide. Unfortunately, if not handled properly, forklifts may be harmful for both workers and spectators.

Forklift data on serious injuries and deaths are frightening. The Occupational Safety and Health Administration (OSHA) states that around 35,000 serious forklift injuries and 62,000 non-serious injuries occur each year.

This page discusses forklift accident statistics, typical types of forklift accidents, the hazards of abusing forklifts, and forklift safety guidelines.

Forklift Accident Statistics

The Occupational Safety and Health Administration (OSHA) estimates that around 1.5 million workers operate over 855,900 motorized industrial trucks, which include forklifts. According to them, forklifts cause around 25% of construction accidents, with 35,000 serious injuries and 62,000 non-serious injuries occurring each year.

Forklift fatalities are less common than nonfatal forklift injuries, although they nevertheless occur. Here are the National Safety Council’s forklift fatality data. (Please keep in mind that nonclassifiable replies and rounding may cause this data to not add up to the total.)

- In 2020, 44 people were killed in forklift transportation incidents.

- Non-roadway forklift events involving motorized land vehicles resulted in 22 deaths.

- Non-roadway, non-collision forklift events resulted in 15 deaths.

- Ten people were killed in non-roadway forklift incidents that involved jackknifing or overturning.

The National Safety Council categorizes nonfatal forklift injuries by industry. According to 2020 statistics, nonfatal forklift injuries are most common in the service, commerce, transportation, and utilities, and goods manufacturing industries.

- Service providing industries: 4,540 nonfatal injuries

- Trade, transportation, and utilities: 4,120 nonfatal injuries

- Goods producing industries: 2,750 nonfatal injuries

- Manufacturing: 1,860 injuries

- Transportation and warehousing: 1,680 nonfatal injuries

- Wholesale trade: 1,360 nonfatal injuriesNonfatal injuries in service sectors totaled 4,540.

- Trade, transportation, and utilities: 4,120 nonfatal injuries.

- 2,750 nonfatal injuries in the goods-producing industries.

- Retail trade: 1,060 nonfatal injuries.

- Construction: 490 nonfatal injuries.

- Natural resources and mining: 410 nonfatal injuries.

- Agriculture, forestry, fishing, and hunting: 230 nonfatal injuries.

- Professional and business services: 220 non-fatal injuries.

- Mine: 180 nonfatal injuries.

- Administrative, support, trash management, and cleanup services: 160 nonfatal injuries.

- Other treatments include 90 nonfatal injuries and 5 fatal injuries.

- Other services, excluding public administration: 90 nonfatal injuries.

- Financial activities: 80 non-fatal injuries.

- Real estate, renting, and leasing: 80 nonfatal injuries.

- Management of businesses and enterprises: 60 nonfatal injuries

- Healthcare and social assistance: 20 nonfatal injuries.

- Education and health services: 20 non-fatal injuries.

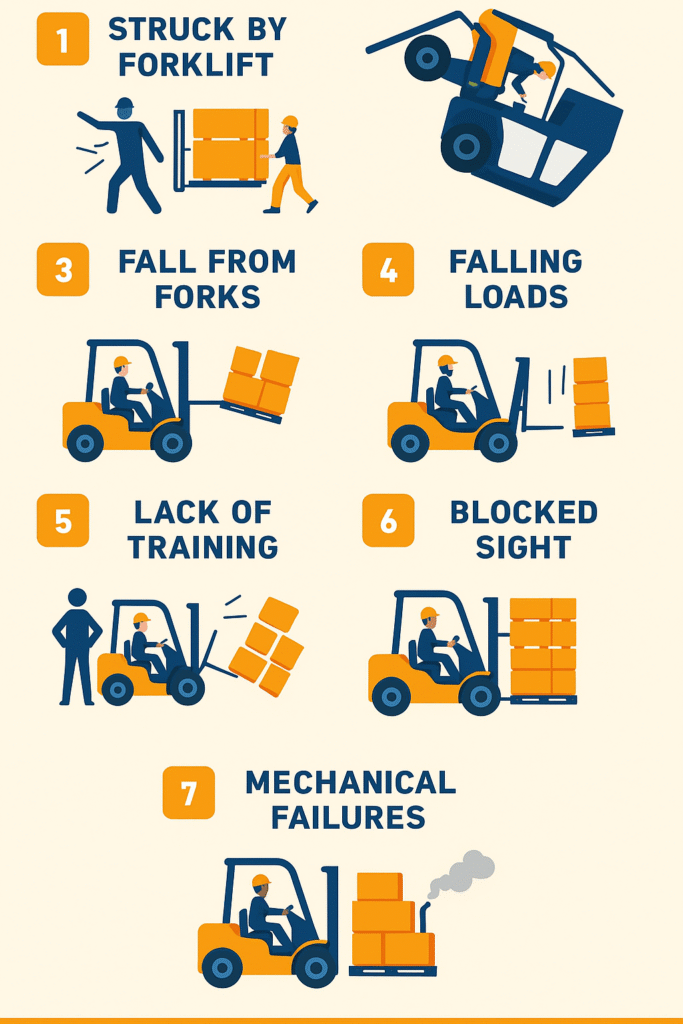

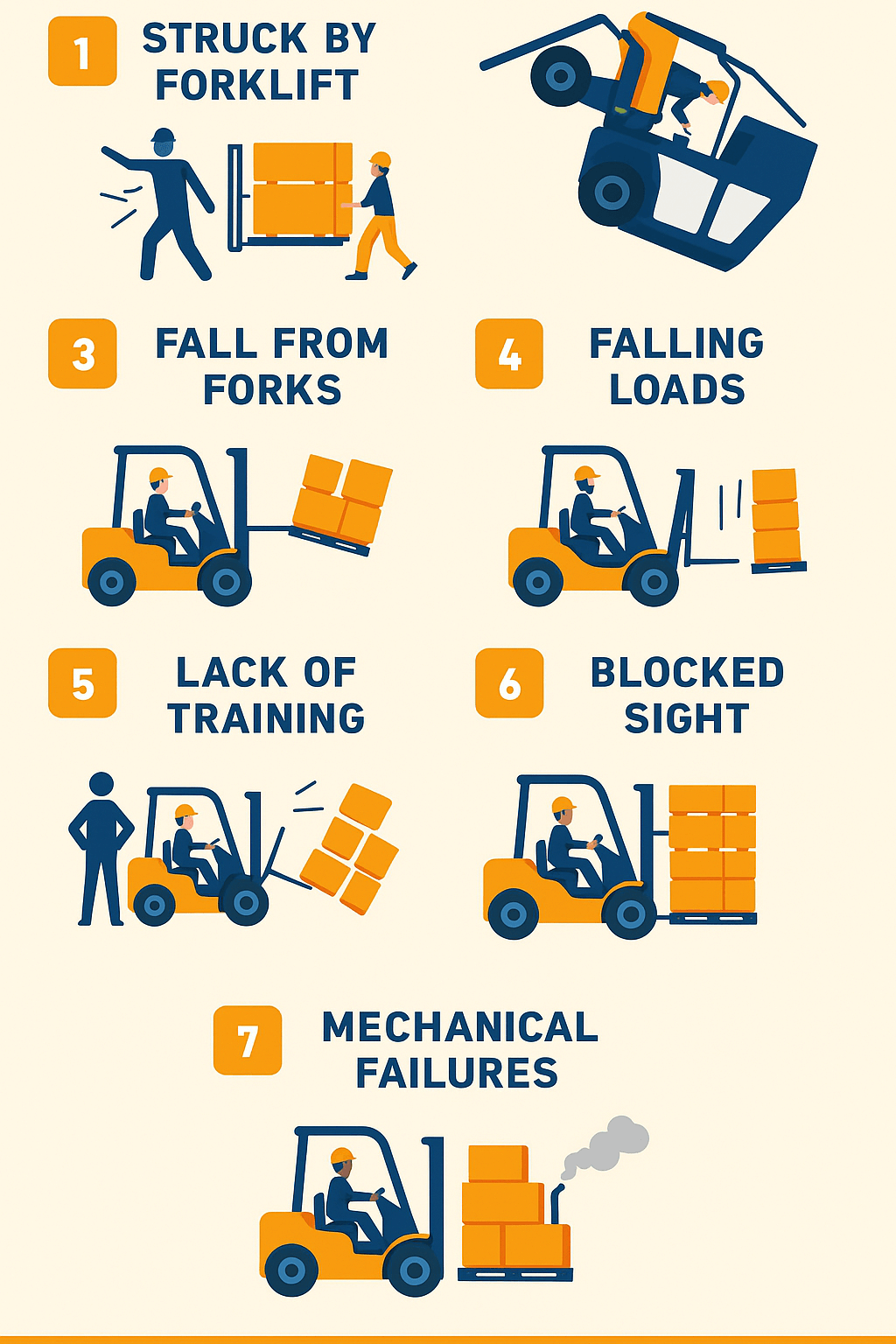

Common Types of Forklift Accidents

Common forms of forklift accidents include being struck by a forklift, injuries from a forklift rolling over, falling off the forklift, being injured by falling cargo, inappropriate operation owing to a lack of training, collisions caused by obstructed eyesight, and mechanical failure.

Precautions such as seat belts, thorough forklift operator training and retraining, and following particular forklift safety requirements in the workplace can prevent accidents by up to 70%.

The first step in avoiding typical forklift accidents is to understand the risks and hazards of driving a big forklift.

1. Being Struck by Forklift

A forklift operator may accidently hit a pedestrian or coworker. One of the most prevalent causes of forklift accidents is when an operator becomes distracted and fails to pay attention, but it may also be caused by dangerous working circumstances that do not provide the driver adequate space or time to react. A lack of warning indications might be the issue here.

Fortunately, mishaps like this may be avoided with basic workplace improvements. Adding floor tape and obstacles to indicate forklift work zones helps alert coworkers and passersby that a forklift may be approaching. Furthermore, enabling workers to relax and take breaks throughout the day will help keep their minds and attention sharp.

Causes

- The operator not paying attention

- A lack of warning signs

Prevention

- Operators should take breaks during the workday.

- Put down floor tape to let pedestrians and workers know that work is being done in that area.

- Add barriers around the forklift work area to keep others from entering.

2. Injury From Forklift Tip-Over or Rollover

Forklifts are large, heavy equipment that are not intended to perform fast maneuvers. If an operator attempts to turn too rapidly or the load exceeds capacity, the forklift may tip over, posing a serious and even fatal risk. Proper forklift operation is critical in preventing rollovers.

Heavy machinery operators should maintain an equal load, avoid turning too quickly, and be cautious of uneven terrain. Maintaining a safe speed limit, keeping loads low, and slowing down as you approach turns are the most effective tactics to avoid this sort of mishap and keep a forklift firmly on ground.

Causes

- Fast turns.

- Unbalanced loads.

- Incline turn

- Uneven surfaces.

Prevention

- Maintain an adequate speed limit.

- Slow down near and around curves.

- Do not exceed the forklift’s weight capacity.

- Maintain the load low to the earth.

3. Falling from Forks or Platform

Personal falls from a forklift are among the most prevalent injuries, yet they are completely avoidable. To avoid falls, operators should always take their time, use the guardrails offered, and follow the required safety precautions.

Do not use a forklift for manlifting. If you need to raise a worker, employ the appropriate equipment, such as a scissor lift or order picker.

Causes

- Failure to utilize the gadget for its intended function

- Trying to be speedy rather than safe.

Prevention

- Take your time.

- Use suitable tools and equipment.

- Use guardrails to prevent falls.

4. Loads Falling from Forklift

Uneven or imbalanced loads can change swiftly and tumble as the forklift drives, resulting in the type of accident that has killed numerous forklift drivers.

Moving too quickly with a load may potentially cause it to topple and fall. When moving a pallet with a heavy load, always keep the weight centered on the forks and avoid going too fast. Tilt the mast back to help steady the weight.

Causes

- Loads are not loaded correctly.

- Move or lift too rapidly.

How to prevent bent lift forks?

- Avoid transporting damaged cargo.

- Center each load.

- Don’t move too quickly when loading or lifting.

5. Lack of Training

Before operating a big piece of machinery, it is critical to have adequate forklift training. A forklift driver should understand the fundamentals of safe forklift operation and be knowledgeable with forklift components that might cause damage.

Accidents caused by a lack of a complete training program can be readily avoided with additional and improved training. OSHA needs certification to use the equipment.

Causes

- Attempts to save money and time through reduced training.

- A belief that training is useless or unneeded.

Prevention

- Enroll in an authorized certification course.

- Read the handbook before using a new machine.

6. Blocked Sight

Part of driving a forklift correctly is seeing where you’re going and avoiding typical forklift safety dangers. Many accidents are caused by objects that block a driver’s line of sight and make it impossible to see the roadway or crossroads ahead. Accidents occur when operators fail to slow down in blind places or when driving with an increased load on raised forks.

Operators may avoid incidents like this by collaborating with a spotter to help them navigate blind regions. Furthermore, driving slowly and with the weight down improves visibility and reduces forklift accidents.

Causes

- Driving with high loads or higher forks.

- Not driving safely across blind places.

Prevention

- Ensure that loads do not impede your eyesight.

- Turn slowly and know your clearance.

- Have a spotter.

7. Mechanical failures.

Even if you are diligent and follow safety precautions, accidents might still occur. That’s because the operator is just one part of the equation: The forklift itself has to be in good shape and properly maintained.

Mechanical failures and breakdowns are major causes of forklift accidents and human harm. Leaking valves and hoses, worn brakes, and damaged tires are all potential causes of accidents.

The good news is that almost all accidents caused by mechanical breakdowns may be avoided with regular shift inspections and forklift maintenance.

Causes

- Insufficient inspections

- Worn-out brakes

- Leaks

- Damaged tires

Prevention

- Perform pre-shift inspections.

- Service your equipment on a regular basis.

- Do not operate on malfunctioning equipment.

The Dangers of Forklifts

Knowing the potential forklift dangers and following safe operating practices will assist operators in avoiding accidents and injuries.

Consider the following variables while driving a forklift:

- Fast speeds can cause injuries. Forklifts are large and cumbersome, yet they can move quickly. A forklift can go up to 18 miles per hour, generating a lot of kinetic energy.

- Breaking is difficult. With their huge weight and rapid velocity, forklifts can be difficult to stop quickly. They frequently feature soft brakes, making it difficult to stop quickly.

- The uneven weight distribution makes operation difficult. While forklifts are extremely powerful, their weight distribution is uneven, making them difficult to handle. Forklifts struggle to make tight turns and navigate small passageways. They’re large and

- cumbersome machines, weighing more than 9,000 pounds, three times that of many vehicles. When a forklift rolls or flips over, a significant amount of weight is displaced.

- The design allows for easy tipping over. Forklifts are prone to tipping over due to their design, which places most of their weight at the back. This hefty piece of machinery spins on its rear wheels, so use caution when driving at high speeds or on varied gradients.

- The line of sight may be impeded. Due to their restricted visibility, forklifts can be difficult to drive. The cargo is carried in the front, obscuring the driver’s vision.

- The loading procedure might result in injury. Forklifts are built to haul enormous loads, making the loading procedure very hazardous. Many incidents on loading docks require material handling.

Forklift Safety Tips

As previously stated, research indicates that accident prevention, including operator training, clear safety standards, and preventive measures, can minimize workplace accidents by up to 70%.

Here are some basic forklift safety precautions to help you stay safe around forklifts:

- Review and follow the manual: Make sure the manner you operate the forklift is acceptable for the vehicle. Do not exceed the weight capability of the forklift. Check your operation handbook to validate the weight restrictions for your specific make and model.

- Operate if you have the required training, licenses, and certificates. Only use a forklift if you are properly trained and licensed. Only rent forklifts that you are acquainted with and comfortable with.

- Wear appropriate clothes. In addition to PPE such as puncture-proof shoes and safety eyewear, forklift operators should wear brightly colored apparel to increase their visibility to other workers, particularly when the truck is in motion.

- Understand the forklift lessons. Understanding forklift classes and which class your truck belongs to, similar to reviewing your vehicle’s operating handbook, helps ensuring you operate it properly, loading it with the necessary weight, and utilizing the required attachments.

- Conduct daily equipment inspections and report any damaged or broken components. Avoid accidents due to poor mechanics and deterioration by avoiding running damaged cars on the floor. Report any damage or issues to a management throughout your shift.

- Maintain complete visibility when operating. Make sure your field of vision is open and unobstructed so you can see what’s in front of and behind you when driving the truck.

- Develop a floor marking system. By designating paths for both forklift operators to drive and pedestrians to walk, a floor marking system helps reduce the potential for truck accidents.

- Place the loads with stability in mind. Although forklifts are designed for material handling, they must nevertheless be loaded cautiously. Depending on the forklift, fork, or attachment you’re using, load pallets and other goods so that the vehicle remains balanced and sturdy. Once the cargo is on the forklift, operate it accordingly, such as not turning the truck while holding a high load.

- Operate the forklift safely. Exercise extreme caution on hills or ramps. Inclined routes may cause a forklift to tilt or move its cargo. Make sure you operate the forklift at a safe speed. To avoid an accident, follow all established speed limits.