How Electric Forklift Winter Maintenance is Best Investment?

Electric forklifts winter maintenance is a very necessary process that ensures a very high level of service for a long time and even in the coldest and harshest winter conditions. For owners and operators, the winter season means that the forklift should be ready for low temperatures, snow, and ice, which are factors that can be a threat to the battery, the hydraulic system, the electrical components, and the safety of the machine.

Today we will share few tips and trick specially curated for electric forklifts winter maintenance by the pure advice of the American Forklifts, which leads step-by-step to the goal of basic winter prevention of electric forklifts.

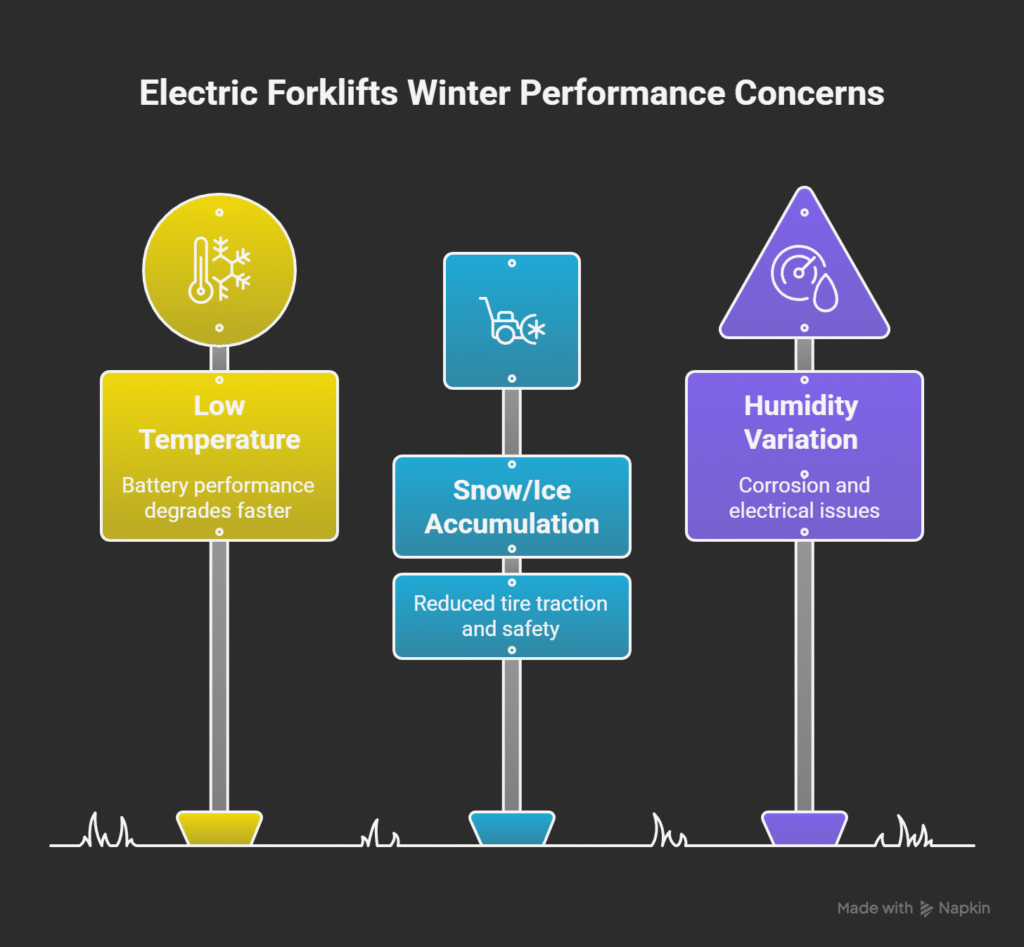

Understanding Winter’s Impact on Electric Forklifts

Electric forklifts winter maintenance is a situation in which every part of the system is under stress, and the batteries, motors, hydraulics, and tire traction components are the most vulnerable ones. When it is below zero, the battery loses power very fast, the hydraulic fluids get thicker, and the motors may still have to exert full power each and every time- all these causes come together to close down your power plant for longer durations.

Hence proper Electric forklifts winter maintenance should not be just a seasonal activity, but a key to ensuring high productivity and saving the machines from getting breakdowns.

- During the cold winter, the battery will be less effective and will have less running time.

- The hydraulic fluids will be thicker so that the speed and control of the lifting can be affected.

- The tires’ grip may be lost because of the ice and snow causing safety problems for the operators.

Table: Major Concerns on Electric forklifts winter maintenance

| Winter Factor | Typical Impact | Recommended Response |

| Low Temperature | Battery drains faster | Use insulated battery covers, charge indoors |

| Snow/Ice | Reduced tire traction | Fit winter tires; clear operating areas |

| Humidity Variation | Corrosion, condensation | Store forklift in dry area; check electrical systems |

1. Battery Protection: The Heart of Electric Forklift Winter Maintenance

The battery packs of electric forklifts face a great deal of trouble in very cold environments when the capacity is reduced to around 30% in subzero conditions.

Both lithium-ion and lead-acid batteries need to be handled with great care in winter and American Forklifts insist on the importance of battery protection measures way before the occurrence of expensive replacements and standstill of work.

Detailed battery proper care paragraphs are the necessity of the manufacturers:

One of the major steps for electric forklifts winter maintenance specifically in winter care is to make sure that the batteries of the forklifts are fully charged, the storage should be in a place with a controlled climate, and when the battery is very cold a battery warmer or an insulation cover should be used.

It is a must that the battery terminals are kept clean and dry at all times, and the electrolyte level is also checked quite often for lead-acid models. As for lithium-ion batteries, the regular diagnostics help detect voltage drops when it is far from the normal condition, thus preventing failures.

- It is a must that batteries are charged indoors or in a place that has a stable temperature during winter nights

- Battery terminals should be checked every week for any presence of corrosion and moisture as part of the electric forklifts winter maintenance

- Electrolyte levels must be checked for lead-acid batteries on a biweekly basis and refilling with distilled water should be done if there is any shortage

Table: Battery Maintenance Checklist

| Task | Frequency | Notes |

| Indoor Charging | Daily | Warmer environment preserves charge |

| Terminal Inspection | Weekly | Prevents power loss, corrosion |

| Electrolyte Check | Biweekly | Lead-acid models only |

| Battery Case Cleaning | Monthly | Reduces conductive buildup |

2. Hydraulic System Care in Cold Conditions

The hydraulic system which is the power of the lift and the tilt mechanism, will be inefficient in winter if it is not properly prepared. Hydraulic fluids will get more viscous in low temperatures thus decreasing the speed of the lift and some leakage caused by the seals can also happen.

Operators must follow detailed steps to keep hydraulics functioning:

Changing to the use of low-temperature hydraulic fluids which are approved by manufacturers, keeping hydraulic fluid at the right level, checking the hoses for leaks or cracks are the essential steps. One of the reasons for poor performance in winter is that the fork is not ready for operation. The hydraulic system will be slow and can cause sudden release of loads. American Forklifts suggests taking oil samples during the winter months to see early contamination.

- Change regular hydraulic oil to a winter-grade oil that is approved by the manufacturer

- Before each shift, always inspect the condition of the seals and hoses for any cracks or leaks

- The engine/hydraulics should be warmed up before using a heavy load

3. Tire and Traction Optimization: Safety of Electric forklifts winter maintenance

Particularly good forklift tire selection and tire maintenance are important when there are snow and ice-covered surfaces in the warehouse or yard. Lack of good traction can lead to the skidding of the fork, resulting in the tip-over of the vehicle or dropping the load, causing both staff and inventory to be at risk.

Operators should use tires aimed at solving the particular problem:

- There are two ways of going about this: one is by equipping the forklifts with winter large percentage solid pneumatic tires if they are working outside, the other is by the utilization of snow chains on the tires.

- Every week the tread depth must be inspected, and the wear pattern should also be recorded to forestall any type of sudden malfunction especially in the middle of the operation.

- One more suggestion from the American Forklifts team is to indoors-store forklifts so as to keep off the wheel rubber hardening and at the same time, maintain maximum grip.

For outside operation, choose either winter pneumatic tires or snow chains. At the beginning of every week, measure the depth of tread and keep a record of it for a specific electric forklifts winter maintenance schedule. Operating areas are free from snow or ice because they have been swept before forklifts are used widely.

4. Electrical System and Connectivity Precautions

Electric forklifts winter maintenance precautions are riddled with electronic controls, sensors, and diagnostic ports, all of which are susceptible to moisture and cold-caused corrosion. Not securing the electrical infrastructure can result in error codes, short circuits, and system shutdowns, which are a very expensive loss of time in the winter period.

Best practices for electrical protection:

Leaks of motor fuel, loose connections, exposed wires, and corrosive materials on electrical terminals can cause serious troubles to forklifts, so weekly inspections must be conducted to locate all these kinds of hazards.

Some advice given by the American Forklifts is that one should put desiccants and other moisture absorbents in the battery compartment and that the system diagnostic should be carried out every time the temperature drops drastically.

- Seal connector parts or wires that are exposed to the elements with waterproof tape

- Put moisture absorbents in places such as electrical panels or battery compartments

- Do a complete electronic diagnostics test during peak winter time once each week

5. Daily Electric Forklifts Winter Maintenance Checklist for Operators

The daily inspection done in a disciplined way is really crucial in winter since it helps somewhat small issues to be caught before they turn into downtime. American Forklifts provides daily checklists that cover every part of a safe operation in the cold, thus making the operators not only safe but also their machines.

Checklists should include:

The first thing to do is to check the visibility of the mast to see if there are any obstructions of ice or snow; then, battery charge levels should be verified; next, all the fluid gauges should be checked, and tire grip confirmed. The lift chain is also always cleaned and lubricated, while, if there are any leaks or electrical issues, they are reported immediately.

- Check for freezing or blockages of the mast, carriage, and lift chain

- Test battery voltage and record charge and discharge rates before starting work

- Look through all the gauges like battery, hydraulics, and hour meter for any signs of warning

6. Storage and Shutdown Guidelines for Forklifts in Cold Weather

If properly stored, the electric forklift can be a big difference for a long time. Forklifts that are left exposed to the cold without adequate protection, can be a source of permanent damage to batteries, electronics, and hydraulic systems. American Forklifts is recommending good ideas for winter storage.

What operators should do:

During the long cold periods, it is a must that the forklifts are stored in indoor spaces that are dry and insulated. Switch off the master power supply disconnect batteries, and put the parking brakes on tightly. Forklifts should be covered with non-woven tarps to avoid getting wet due to the formation of condensate.

- Park forklifts in heated warehouses, if possible

- Remove batteries if going to be at a long stop without using the vehicle

- Forklifts can be covered with moisture-wicking and breathable covers

7. Operator Safety: Winter-Specific Tips

Operator safety is a very important issue that should be specially taken care of when the temperature drops as cold stress, low visibility, and slippery surfaces are becoming the risk factors along with the mentioned ones.

One of the points in the program of Electric Forklifts winter maintenance, which is necessitated by focused operator training and protective gear, is the operator’s safety.

Key operator safety bullet points:

Some of the specific cold weather safety issues include the provision of high visibility gear, insulated gloves, and insulated boots for the newly employed workers. Forklift drivers must have a clear method of communication for reporting that they have found hazards and at the same time they should get regular safety drills for practicing emergencies like panic situations.

- Give operators the necessary equipment like gloves, boots, and high-visibility jackets which are for insulating purposes

- Besides weekly safety briefings and emergency drills concentrating on winter hazards, also conduct other training courses

- Always keep communication channels open for linking any safety issue or mechanical problem

8. Electric Forklift Winter Maintenance Planning and Scheduling

The core of successful electric forklift winter maintenance is regular scheduling and documentation. According to American Forklifts, seasonal calendars and digital logs should be created so that during winter no important check or adjustment is missed.

Best practices for planning:

- One of the best times to set up winter maintenance schedules is usually before October, this means that the transition will be very smooth.

- Battery service records, fluid changes, inspection results as well as repair details should all be included in the logs.

- Register the changes that are to take place in the winter by mid-autumn in order to get the best results

- Be very accurate in keeping logs for every maintenance activity and inspection

- Community Winter Maintenance Resources can help you schedule preventive visits at least twice a month.

9. Environmental Considerations: Sustainability and Efficiency

Winter maintenance that alleviates efficiency concerns should also take into account the environmental responsibility side of the equation.

American Forklifts suggests the implementation of green practices for electric forklifts, including recycling the used fluids, properly disposing of the used batteries, and reducing the idling periods as much as possible.

Operators and facility managers should focus on:

The implementation of green technology solutions such as the use of LED lighting that is highly efficient for warehouses, using bio-friendly hydraulics and lubricants, and practicing battery recycling most responsibly are also actions that can save the forklift investment as well as the local environment at the same time.

- Recycle hydraulic fluids and lubricants following the set regulations in your area Cut down on forklift idling and use energy-saving warehouse infrastructure

- Encourage battery recycling programs and the use of disposal methods that are environmentally friendly

FAQs: Electric Forklifts Winter Maintenance

How does cold weather affect electric forklift batteries?

In cold weather the batteries of electric forklifts lose their capacity significantly and the result might be that they get drained quite fast. The best way to keep them running well is to put on battery insulation and charge them indoors.

What type of hydraulic fluid should be used in winter?

The use of low-temperature, manufacturer-approved hydraulic fluids is what is recommended if one wants to keep the lift at normal speed and avoid any kind of system freeze in electric forklifts.

Should forklift tires be switched for winter?

It is safer and better to use winter-grade solid pneumatic tires to replace the standard ones if the forklifts are intended to be used outdoors. Or alternatively, snow chains may be used to increase tire traction in winter.

How often should electric forklift batteries be checked in winter?

It is necessary to inspect batteries weekly and in the case that a forklift is used frequently as part of the electric forklifts winter maintenance, then the battery state of charge should also be monitored daily.

What is the best way to store electric forklifts during extended cold spells?

The best place to keep them is indoors in a heated space. It is also a good idea to disconnect batteries and cover forklifts with breathable tarps so that the moisture does not cause damage to them.

Are operator safety protocols different in winter?

Indeed, the winter-specific safety gear, the briefings and the hazard reporting that being essential parts in the prevention of cold stress and of accidents comprise the safety protocol for the winter period by the American Forklifts.

How can maintenance logs improve winter care?

They can be either digital or physical and will be of great help in making sure all the necessary tasks are carried out, helping identify breakdowns in patterns and simplifying scheduling.

Conclusion: Winterizing Electric Forklifts for Maximum ROI

If one adopts a systematic approach to the winter maintenance of electric forklifts the machines are not only protected but also the owner reaps enormous returns in the form of minimal downtime, maximized safety, and extended service life.

Thus, American Forklifts being the most reliable industrial teams resource of expert for electric forklifts winter maintenance, are the checklists, care tips, and planning tools that businesses with such capabilities of facing the most severe cold weather may want to consider so as to keep high efficiency and to protect their every forklift investment for years to come.