Is It Safe to Leave an Electric Forklift Charging Overnight? A Complete Guide to Safety and Best Practices

It is a well-known fact in the material handling and logistics industries that maximizing uptime equates to maximizing profitability. Therefore, for warehouse managers and forklift operators, the end of the day always marks a moment of decision: Is it safe to leave an electric forklift charging overnight? Strictly speaking, yes—charging your electric forklifts overnight is a standard practice in the industry and, when done correctly, it allows your fleet to be operational for the next day’s work without problems.

Nevertheless, behind the façade of this convenience lies a set of safety costs that are not insignificant. Unattended charging of potent industrial batteries for a prolonged period, say 8 to 12 hours, is not something to be taken lightly and it requires well-defined safety measures in place to ensure that the risk of fire, hydrogen gas explosion and electrical faults is minimized.

You need to be familiar with the characteristics of your battery whether it is the usual sealed lead acid or the newer lithium-ion type if you want to keep your work environment safe as well as your expensive equipment effective for a long time. In the following paragraphs, you will find detailed information on the different aspects of charging overnight, the essential “8-8-8 rule,” and how to do it in absolutely safe conditions.

The “8-8-8 Rule” and Why It Matters for Overnight Charging

Historically, the “8-8-8 rule” has been at the heart of lead-acid battery care in the forklift industry and it is mostly responsible for the widespread practice of overnight charging. The rule describes the life cycle of a lead-acid battery as consisting of 8 hours usage (one work shift), 8 hours charging, and 8 hours rest for cooling.

Charging during the night is, therefore, the best physical and chemical medium for the battery to completely recover its energy. But, in addition to enabling the charge cycle, following the “8-8-8” rule is synonymous with chemical stability. When charging an electric forklift battery overnight, you are effectively recharging the chemical state of the battery.

If this is done at haste, the battery could undergo irreversible damages occurring internally, such as sulfation and overheating of the battery plates, which can result in a shortened battery life.

- Eight Hours of Operation: This is the usual discharge time when the forklift is used. The battery shouldn’t be discharged below 20% because deep discharge will harm levels and cause electronic sulfation of the battery cells.

- Eight Hours of Charging: The battery is hooked up to the charger during this time. Nowadays, chargers can communicate with the battery and decide by themselves when the battery is full and to interrupt the charge cycle automatically. This is a great feature, especially for an overnight charging session.

- Eight Hours of Cooling: Usually the most overlooked step, cooling is essential. Besides generating heat, lead acid batteries make use of chemical reactions that can be highly affected by temperature factors. As a matter of fact, charging a battery and immediately using it could result in plates warping and loss of efficiency due to the deterioration of the electrolyte solution.

Understanding the Risks: What Can Go Wrong Overnight?

Apart from being technically safest, an electric forklift should charge overnight with the correct charger and equipment. Charging the battery when it is not supervised, however, increases the risk element, which means safety managers must come up with solutions for possible problems.

Most fire accidents involving batteries are caused by runaway thermal reactions. Thermal runaway is the condition when the heat produced by the battery is more than the heat dissipated by the battery, and in such cases the battery would go to fire or explosion.

This can happen when the charging equipment is old or badly maintained or if there is some sort of damage to the cell of the battery. Another issue is that the process of charging lead-acid batteries gives out hydrogen gas, which is highly flammable. If the warehouse doors are bolted shut for the entire night without proper air circulation, a spark caused by a light switch or a faulty wire could set the gas on fire and cause an explosion.

- Hydrogen Gas Accumulation: At full charge, batteries “gas off” thus generating hydrogen. If no proper ventilation or a ventilation fan is not operating during the night, the gas can accumulate in the ceiling or in the charging bay causing an explosive risk.

- Electrical Faults and Shorts: It is possible that frayed and exposed cables, damaged connectors, or the wear of insulation on charger cables result in a spark. Since the fault happens when no one is around, the consequence may be a structural fire resulting from a minor electrical fault turning into a major one over time.

- Water Levels and Boil-Overs: Overfilling a battery with water before charging can cause the electrolyte to boil over when the battery temperature rises as a result of the charge, spilling sulfuric acid that corrodes the floor and creates a dangerous slipping hazard for the next shift.

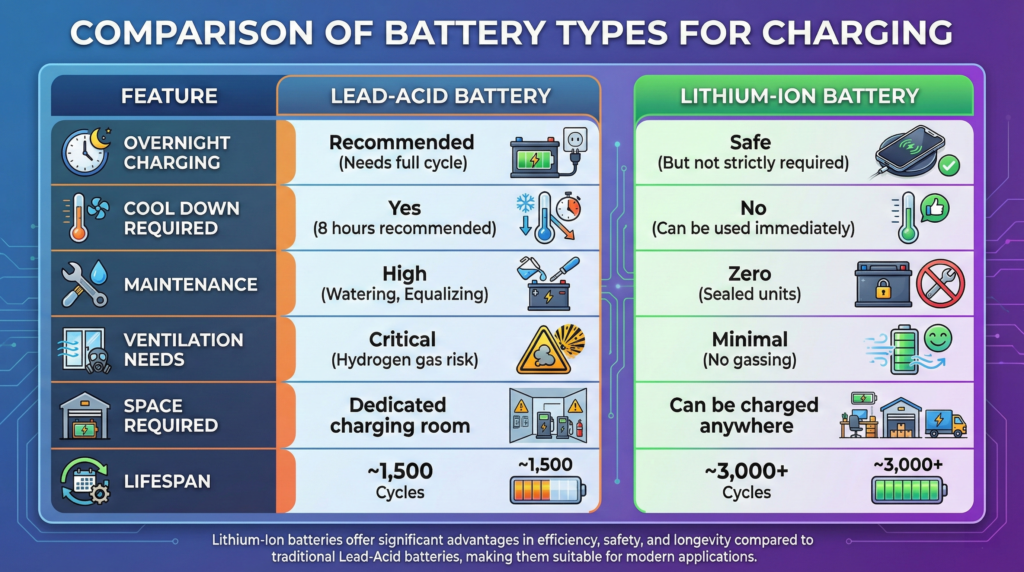

Lead-Acid vs. Lithium-Ion: Different Rules for Different Batteries

There are so many differences between lead-acid and lithium-ion batteries, that the safety guidelines for charging electric forklifts overnight ones can be so different that at times they seem to be contradictory at times.

A dramatic trend towards lithium-ion adoption for forklift batteries motivated pure mobile energy delivery to meet stricter emissions and efficiency targets, but the co-existence of legacy and new battery sets represents the present for many of us in the sector.

Lead-acid batteries are traditional tanks that hold the liquid inside and thus have weight and require considerable amount of water and that need to be taken care of in terms of maintenance and the charging cycle control very strictly. One of their major advantages is the ability to be charged overnight by the strict application of the 8-hour charging rule.

On the other hand, lithium-ion batteries come in totally sealed cases and are very different in that they don’t emit gas, do not require water and in theory you could even leave them on charge for an extended time without worrying about “gassing” or acid spills.

More importantly, lithium batteries should not overcharge because they have protective systems that rely on a Battery Management System (BMS) to do this task.

- Lead-Acid Maintenance: These batteries require a specially designed charging area that is resistant to acid attack and with an eyewash station nearby. Electrolyte levels must be checked regularly, and never be topped prior to charging, as the volume of the solution will expand in the process.

- Lithium-Ion Flexibility: When a battery spends its lunch breaks “opportunity charging” and not having the full eight hours cooldown, it is preferred. The BMS will disconnect the battery from the power supply when it is full as a safety precaution, so the battery can be left plugged in overnight without any worries.

- Charger Compatibility: A big mistake is to use a non-compatible charger. For example, trying to use a lead-acid charger to the lithium battery (or vice versa), may cause the BMS to be destroyed, the battery to be aborted or even to end in a fire!

Setting Up a Safe Overnight Charging Station

If you want to be sure that it is safe to leave an electric forklift charging overnight, then having an OSHA-compliant, dedicated charging station is a must. This means that the stations are not simply a section of the warehouse floor, but instead a location that has been designed with the specific purpose in mind of confining accidents.

There should be no loose rubbish, cardboard or any other kind of combustible materials in the vicinity that could get set on fire if there is a spark. Besides this, where the forklifts are positioned is also crucial. Walking to your forklifts and bringing them to the charging station, you first set the brakes, lower the forks, and turn off the ignition.

Once you are done charging, you unplug your chargers and take care of the cables, by hanging them up or retracting them to prevent any damage if forklifts run over them, which is normally the cause of electrical fires and cable degradation.

- Adequate Ventilation Systems: Make sure that you have air systems out or bring in fresh air to remove the hydrogen. The smart move is to buy hydrogen monitors; these are capable of triggering an alarm and/or turning on the ventilation system automatically if gas concentration increases and the building is vacant.

- Fire Safety Equipment: The first thing for fire safety is to make sure that there is an extinguisher at hand and that it is rated for electrical and chemical fires (Class C and B). A fire sprinkler system should be installed in the charging room.

- Collision Protection: Just a few protected areas are enough with guard rails or bollards installed around the chargers. A tired forklift operator at the end of their shift is very likely to reverse his vehicle to the wrong side and hit the charger, which will break the internal parts and lead the charger to malfunctioning during the overnight charge cycle.

The Role of Battery Maintenance in Safety

Charging electric forklifts overnight is a risky business if the battery is not in the best possible condition. Batteries with loose connections and corroded terminals, cracked battery case or exposed cells are basically time bombs.

Regular inspection and maintenance of the battery is the most effective way to prevent injuries and super-charge a worker productivity through safety. Such maintenance includes cable inspection for he copper exposure, inspection of connector heads for pitting and burning as these signs indicate that there is electrical arcing, and making sure the battery surface is clean and dry. In fact, any acid spill on the top of the battery will create a conductive path through which the current will flow and this will lead to self-discharge or even short circuiting.

Watering lead acid batteries is quite a delicate matter since you cannot go on adding water or letting the water get over the plates unchecked without serious consequences. This results in sulfation if there is not enough water; whereas too much water leads to acid spills which can be very dangerous.

- Cable and Connector Inspection: Once you strip the plugs of their covers, look out for cuts, wear, or signs of burning. If a plug is loose it will generate resistance which in turn produces heat. So, a plug which after usage feels warm has to be replaced immediately and it should never be used for overnight charging.

- Sulfation Prevention: With no charge for the battery, the build-up of sulfate crystals on the battery plates is inevitable. This causes an increase of the internal resistance and may result in the charger misinterpreting the battery state, which in turn may cause overheating or worse.

- Equalization Charges: Lead-acid batteries subject to equalization charges are periodically recharged after a normal charge is completed to redistribute the electrolytes and synchronize the voltage of each cell. They can only be performed manually or with software-controlled chargers during attended shifts or according to manufacturers’ operational procedures if done during unattended shifts.

Why Charger Technology is Your Safety Net

Given the great degree of sophistication of today’s charger technology, it is safe now to say that you can comfortably leave an electric forklift charging overnight. Modern industrial chargers are not just simple devices but rather smart computers that are capable of giving continuous feedback about the battery, measuring its voltage, temperature, and internal resistance in real-time.

The high-frequency charger changes the amperage output second-by-second to one more that the battery can absorb. This, of course, results in a lower level of heat generation. However, one of the main features of such chargers is that they can “auto-stop” charging to prevent the battery from getting overcharged.

Once that the battery charge state reaches 100% the charger ceases to supply current. Actually, some chargers will switch to “trickle” or “maintenance” mode to keep the battery topped up without overcharging it, which is essential for weekends or holidays when the forklift might sit for days.

- Temperature Compensation: Some smart chargers are equipped with sensors (usually attached to the battery cables) to measure the battery’s temperature. If the battery overheats, the charger either reduces the current or interrupts the cycle temporarily to allow cooling.

- Auto-Start/Stop: If electricity goes out half-way during the night, the charge cycle safe-restart protection will allow the charger to resume the correct program profile once power is restored, to prevent damage to a partially full battery.

- Data Logging: The advanced chargers keep recording every charge cycle. These records are handy for the fleet managers who want to be 100% sure that the operators actually plug in the trucks at the end of the day and also for diagnosing the reasons behind battery failures or overheating.

Comparison of Battery Types for Charging

| Feature | Lead-Acid Battery | Lithium-Ion Battery |

| Overnight Charging | Recommended (Needs full cycle) | Safe (But not strictly required) |

| Cool Down Required | Yes (8 hours recommended) | No (Can be used immediately) |

| Maintenance | High (Watering, Equalizing) | Zero (Sealed units) |

| Ventilation Needs | Critical (Hydrogen gas risk) | Minimal (No gassing) |

| Space Required | Dedicated charging room | Can be charged anywhere |

| Lifespan | ~1,500 Cycles | ~3,000+ Cycles |

Frequently Asked Questions – Electric Forklift Battery

Can a forklift be left charging all weekend?

Most of the time, it is safe to leave a forklift charging throughout the weekend because an advanced charger will stop charging automatically once the battery is full. Moreover, the charger switches to “maintenance mode” or “trickle charge” to keep the battery charged without overcharging it. This is, however, under the condition that the water level is correct (for the lead-acid battery) before the weekend starts.

Is charging a forklift battery overnight harmful to it?

Overnight charging is really a good thing for lead-acid batteries since it allows them to get fully charged and at the same time cooled down as required by the 8-8-8 rule. On the other hand, interrupted charging or “short cycling” has a more damaging effect on lead-acid units.

Do forklift batteries release gas while being charged?

The gas that is released from lead acid batteries is hydrogen gas and it is more especially toward the end of the charge. For this reason, proper ventilation is absolutely necessary. During normal charging, lithium-ion batteries are sealed and thus, do not give out any gases.

What does the 8-8-8 rule mean for forklifts?

It implies that the forklift battery should be used for 8 hours, charged for 8 hours and cooled for 8 hours. The cycle can help a lead-acid forklift battery to last longer and it also protects it from the risk of overheat.

When should I add water to the forklift battery, before charging or after charging?

Water should always be added after the end of charging cycle. Heating of the electrolyte and expansion occurs during the charging; if you fill it up before charging, then there will be overflow with acid spill. Only add water before you charge if the plates are exposed and dry (just enough to cover them).

How often does a forklift battery have to be equalized?

Lead-acid batteries often require an equalization charge after 5 to 10 charge cycles. This is a planned overcharge that works to remove the sulfate from the plates. For the exact timing, you should consult your battery manufacturer’s manual.

Is it okay to charge a lithium-ion forklift battery with a lead-acid charger?

Absolutely not. Lithium-ion batteries need a particular charging profile that has constant current and constant voltage (CC/CV) stages. The battery management system (BMS) could be damaged, the battery could fail or even a fire can be started if a lead-acid charger is used.