Maximizing Warehouse Efficiency with Reach Truck: The Ultimate Guide to Narrow Aisle Forklifts for Tight Spaces

Logistics and warehousing industries are constantly changing, and space has become the most valuable commodity. With the continuing growth of businesses and their inventory, one of the biggest issues is how to fit more stuff in the same space. This is the kind of challenge that can be handled perfectly with the help of Narrow Aisle Forklifts such as Reach truck.

These specialized forklifts are not like your regular counterbalance trucks that need a lot of maneuvering space, on the contrary, they are specially designed to move through extra narrow aisles, which means warehouse managers can cut the aisle widths sharply and raise the storage capacity vertically. Thanks to these clever machines, the storage area can be accommodated up to 50% more without any facilities expansion.

Moving to narrow aisle equipment entails more than just a space-saving solution; it is a strategic decision geared towards achieving higher operational efficiency, more safety, and ultimately a greater throughput. Whether an old warehouse is being renovated or a new distribution center is being built, acquiring knowledge about the operations and advantages of these forklifts is the first move towards your optimization goal.

Understanding the Narrow Aisle Forklift Landscape

A Narrow Aisle Forklift is a type of material handling machinery that has been specifically made for stacking and retrieving of goods in aisles whose widths are much thinner than the ones needed by normal conventional forklifts.

Where a regular forklift would have to have 12 to 14 feet of space to maneuver, narrow aisle forklifts can run efficiently even in aisles as narrow as 8 to 10 feet, and VNA (Very Narrow Aisle) models can go down even smaller. These vehicles manage to do that by having very compact chassis designs and masts that can lift loads very high and with absolute precision.

They are essentially the machines behind the dense storage systems found in e-commerce fulfillment centers, freezer warehouses, and parts distribution.Modern warehouses that are turning to these types of vehicles are doing so to increase the volume utilization of their buildings – i.e. by packing the entire space rather than only the floor area.

- Reach trucks: are considered the most common narrow aisle forklift type, and have a pantograph mechanism for the forks, which extends them forward for getting/storing pallets.

- Order pickers: were made with the capability of lifting the operator with the forks so that personnel piece picking from high shelves is possible and not only the movement of full pallets.

- VNA turret trucks: are very special machines where the forks rotate a full 180 degrees, thus the operator can stack loads on either side of the aisle without having to turn the vehicle itself.

- Articulated forklifts: have a rather uncommon feature in which the forks can swing separately from the truck body allowing maneuvering in tight corners to be done easily.

The Strategic Benefits of Choosing Narrow Aisle Forklift

Besides merely fulfilling a space-saving function, installing a Narrow Aisle Forklift system will raise your game in many areas. Hence, the key benefit of being able to close down the racking in a more condensed space while still maintaining the same amount of operational efficiency and safety cannot be overemphasized.

A simple example is when you close the aisle from 12 to 6 feet and so you are, in theory, able to double the number of pallets that can be stored in the same area. What is more, all the above trickles down to operational efficiency and safety as well.

Working with precision is the purpose of these machines and therefore the builders often equip them with advanced guidance systems (wire or rail) that reduce the chance of the truck hitting the racks thus keeping your infrastructure and merchandise safe.

Additionally, operator performace will be boosted because engineers have included better ergonomics in the lifts giving the operators increased visibility and less tiredness during the work shift. This combination of density and precision makes them indispensable for modern, high-volume warehouses.

- Greater Storage Capacity: A simple thought experiment illustrates that if you reduce the aisle widths from 12 feet to 6 feet, you are effectively doubling the number of pallet positions that can fit into a warehouse.

- Improved Safety Features: Many models are fitted with height selection mechanisms and will automatically slow down when the mast is raised to prevent the lift from tipping over.

- More Selectivity: When you compare with bulk stacking or drive-in racking systems, narrow aisle configurations provide you with 100% selectivity most of the time implying that every pallet can be accessed at any time.

- Lower Costs: By using the space you already have to the fullest, you are delaying or even avoiding the necessity of an expensive extension of your facilities or renting additional storage space off-site.

Comparing Narrow Aisle Forklifts and Scissor Lifts

Although Narrow Aisle Forklifts and scissor lifts are both regularly found in industrial settings, their functions are quite different yet at the same time complementary. A scissor lift mainly focuses on personnel as it is essentially a platform that elevates workers and their tools vertically for maintenance, installation, or inventory checking.

The large and stable platform feature, in particular, makes it a good option for these tasks but the design doesn’t allow for the transport of heavy palletized goods. Comparatively, narrow aisle forklifts are primarily used for handling materials.

Yet, it’s not uncommon to run across both working closely together wrapped up in each other’s embrace for the majority of the time in the tightly packed warehouse settings. The main operator of the forklift does the heavy lifting of the stocks while the narrower aisle scissor lifts are running around handling the maintenance crews to tackle such issues as light fixtures, damaged shelves, repair of heating and ventilation systems in the aisles.

Hence, it could be said that both share a similar design rationale: small footprint for maximum accessibility.

- Main Use: Forklifts for Material Handling and Pallets; Scissor Lifts for Personnel Maintenance.

- Vertical Advantage: Forklifts have a mast and a carriage; Scissor Lifts have a pantograph (CR) or vertical mast.

- Platform Feature: Forklifts come with forks or clamps; Scissor Lifts are equipped with a railed platform plus control boxes.

- Sharing these kind of spaces: both are indispensable in the high-bay warehousing where there is no other way to grow but “up”.

Operational Safety and ANSI Standards

Working with industrial vehicles in tight spaces such as with Narrow Aisle Forklifts requires a greater focus on safety not just for the operators but also for the surrounding environment. If we were to think of the similar ANSI standards that we often talk about and compare those to the scissor lifts, we could find that, like with scissor lifts, OSHA has also set regulations for forklifts that call for proper training, maintenance, and operation.

Considering the fact that these machines are sometimes mere inches away from the racks, and at times, both the racks and people, the potential to cause harm is very great. Therefore, it is very important that the operators be well-trained with specific practical knowledge and experience of the equipment conductor, a simple counterbalance license shall not be accepted as proof of competency to operate a reach truck or a turret truck.

Besides, the warehouse also needs to be upgraded with safety measures such as end-of-aisle guards, convex mirrors, and pedestrian warning systems, e.g., blue lights, to reduce accidents in the blind spots.

- Specialized Training and Evaluation: OSHA mandates that operators are trained and tested on the specific class of powered industrial truck they will use regularly and the evaluation must be done on the same actual equipment.

- Pre-Shift Forklift Inspection: It is the operator’s responsibility to conduct a thorough walk-around to check the complete unit including the hydraulic hoses, battery charge, brake system, and tires to make sure it is in good working condition before starting work daily.

- Strictly No Pedestrians in Forklift Aisles: To segregate foot and vehicle traffic, it is mandatory to have clear rules in place and follow them to the letter as pedestrians cannot escape the forklift if it comes close to them in the narrow aisle.

- Load Capacity Awareness: Operators are knowledgeable about how lift height can affect load capacity (de-rating) so that tip-overs are avoided when loads are raised to a great height.

Power Sources and Maintenance for Tight Spaces

Electric power is the main source for the vast majority of the Narrow Aisle Forklifts. Without a doubt, this is a deliberate and necessary decision for several reasons. Basically, the majority of their operations take place indoors where natural ventilation may be inadequate.

For this reason, the use of electric battery-powered vehicles becomes imperative in terms of air quality. Another reason is that the electric motors are capable of delivering the kind of torque that comes on tap right away as well as a high degree of control necessary for the fractional movements when inside narrow racks.

The maintenance routine of these forklifts is quite different from that of the internal combustion engines. It heavily depends on battery care, namely watering, equalizing, and opportunity charging, but also on the hydraulic systems. The industry is rapidly leaning toward Lithium-Ion batteries; these batteries last longer between charges, get fully charged faster, and require no maintenance as opposed to the typical lead-acid battery.

This allows the forklifts to operate without interruption for the multiple shifts which, in turn, removes the need for a room dedicated solely to the battery change thus another great space-saving move.

- Battery Maintenance: Regular watering and equalization for lead-acid batteries are critical to prevent sulfation and extend lifespan.

- Hydraulic Systems: Regular checks for leaks are vital, as a hydraulic failure in a narrow aisle can strand a load at height.

- Tire Care: Cushion tires are standard for indoor use; they must be inspected for chunking or debris which can destabilize high lifts.

- Cleanliness: Keeping the warehouse floor free of debris is more critical for narrow aisle trucks, which often have lower ground clearance.

Selecting the Right Equipment for Your Facility

The selection of the right Narrow Aisle Forklift for your warehouse is primarily driven by the layout of your premises, the weight of your goods, and how high you want to be able to reach. Reach Truck is a pretty flexible piece of equipment that performs well even if the aisles are perfumed with 8-9 feet.

In case you need to go narrower (below 6 feet) and higher (30+ feet), the VNA Turret Truck is definitely the better option but you will have to pay more initially and ensure that the floor is perfectly level since this type of truck does not cope too well with uneven surfaces.

The “Order Picker” will only suit you if the majority of your operation consists of case picking rather than full pallet moves. A material handling expert must be called in to survey the site so he/she can measure the existing aisle width, evaluate the floor quality (superflat floors are typically required for VNA), and furnish the truck that will offer the best balance of cost, capacity, and throughput.

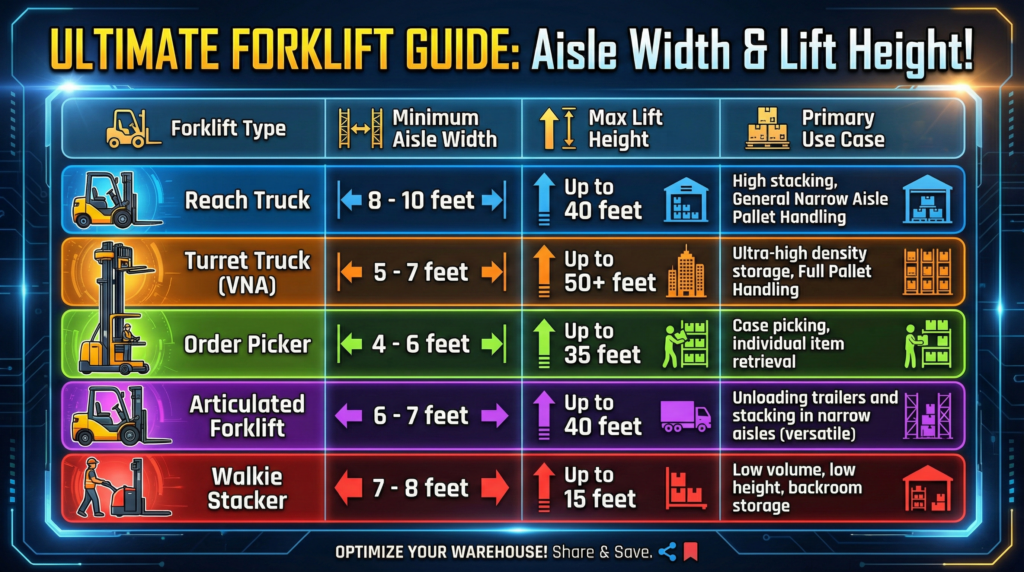

Table: Reach Truck – Narrow Aisle Forklift

| Forklift Type | Minimum Aisle Width | Max Lift Height | Primary Use Case |

| Reach Truck | 8 – 10 feet | Up to 40 feet | High stacking, General Narrow Aisle Pallet Handling |

| Turret Truck (VNA) | 5 – 7 feet | Up to 50+ feet | Ultra-high density storage, Full Pallet Handling |

| Order Picker | 4 – 6 feet | Up to 35 feet | Case picking, individual item retrieval |

| Articulated Forklift | 6 – 7 feet | Up to 40 feet | Unloading trailers and stacking in narrow aisles (versatile) |

| Walkie Stacker | 7 – 8 feet | Up to 15 feet | Low volume, low height, backroom storage |

FAQs: Reach Truck – Narrow Aisle Forklifts

Can narrow aisle forklifts be used outdoors?

Generally, the majority of narrow aisle forklifts, mainly reach trucks and order pickers, are intended for indoor usage on smooth and level concrete floors. Their small cushion tires and low ground clearance make them unsuited for uneven outdoor surfaces, gravel, or asphalt. That said, some articulated forklifts have pneumatic tires that allow them to be used both outdoors (for unloading trucks) and indoors (for stacking shelves), thus they play a dual role.

Do I need a special license to operate a narrow aisle forklift?

Definitely, according to OSHA regulations, individuals operating forklifts must be trained and qualified to operate the specific type of forklift they drive. A license for a conventional sit-down counterbalance forklift will not suffice for operating narrow aisle models such as reach trucks or order pickers. These types of equipment employ different controls, directions of travel (you may be reverse steering more frequently), and have different stability characteristics which is why they require specific training and practical evaluation for certification purposes.

How does wire guidance work for VNA forklifts?

Wire guidance systems consist of a wire embedded in the concrete floor along the center of the aisle through which an electrical current is passed. Narrow Aisle Forklift sensors detect the magnetic field of the wire and thus the forklifts are automatically steered in perfectly straight lines. By doing this, the lift operator can be totally focused on elevation and lowering of the goods, without worrying about the steering or the racks. Rail guidance (mechanical rollers) is an alternative method.

What is the difference between a reach truck and a turret truck?

The forks of a reach truck are mounted on the side of the mast and the operator “reaches” out the forks to put the pallet in the location; the truck most of the time has to make a 90-degree turn so that it will face the rack. A turret truck has a mast that does not move but the forks themselves rotate 180 degrees; hence, the operator can pick from both sides of the aisle without having to turn the truck allowing the aisles to be made much narrower.

How high can narrow aisle forklifts reach?

Narrow aisle forklifts are fully capable of reaching great heights. Typically, Standard Reach Trucks can stack pallets 30 to 40 feet high. VNA turret trucks at the higher end of the scale and specially made order pickers can exceed heights of 50 feet (15+ meters), therefore allowing warehousing facilities to make full use of the vertical space in their buildings. It should be noted, however, that the lift capacity reduces (is derated) as the height increases.

Are narrow aisle forklifts more expensive than standard forklifts?

It is generally true that the advanced narrow aisle equipment such as reach trucks and VNA turret trucks cost more upfront than a standard sit-down propane forklift as they are more complex in terms of technology and engineering. On the other hand, the benefit (ROI) comes from the drastically reduced cost of floor space. By storing 30-50% more goods in the exact same building, price per pallet position is effectively lowered over a period of time.