Electric Forklift Fire Extinguisher: Ensure your safety! Explore our comprehensive guide

Changing the source of power in the material handling industry from internal combustion engines to electric power made a big difference in safety. American Forklifts, for example, offer electric fleets, and many businesses in the USA are going this way. No wonder, safety managers and warehouse operators are constantly asking the same question: Is there a need for electric forklift fire extinguisher?

Electric models don’t burn petroleum derivatives such as diesel or propane, but there are extremely large lead-acid or lithium-ion battery packs that can be exposed to thermal risk. To be able to keep a work environment that is safe and conforms with the law, it is important to know the three areas: OSHA regulations, NFPA standards, and the manufacturer’s advice.

It is not only the prevention of forklift crashes that makes a warehouse a safe place; we also have to be ready for the less frequent cases. Although electric forklifts do not release harmful gases and are less noisy, unfortunately, the batteries which store very dense energy may be a source of danger if there is a short circuit or the so-called “thermal runaway”.

The question of whether or not an electric forklift fire extinguisher should accompany forklift remains unresolved. The reason being, unlike the petrol-powered ones, electric forklifts don’t come with a built-in space for the fire extinguisher.

When we consider the immediate surroundings of these machines-stacks of wooden pallets, plastic wraps, and cartons – it becomes quite evident that having an extinguisher handy would-be a plus.

What Electric Forklift Fire Extinguisher is OSHA and NFPA Talking About?

The rules around electric forklift fire extinguisher installation on forklifts include a lot of subtleties. The main laws in this area are set by OSHA (Occupational Safety and Health Administration) and the NFPA (National Fire Protection Association).

OSHA 1910.178 is specifically about Powered Industrial Trucks and OSHA has a lot to say about the environment as well as the fuel type. The case of electric forklifts is different without fuel leaks, the fire threat is from the electrical fire and the environment around the battery charging area.

- Precise Location: Federal OSHA does not clearly state that an extinguisher has to be on every electric forklift, but it does indicate that extinguishers should be easily accessible in the areas where forklifts are operated and charged.

- Hazard Ratings: When dealing with electrical vehicles, the extinguisher must be suitable for Class C (Electrical) fires. A water-based extinguisher used on a battery fire can cause severe electrocution or even explosions.

- Local regulations: Various state-level OSHAs (such as Cal/OSHA) and local fire marshals tend to have more stringent rules which might require a mounted extinguisher irrespective of the power source of the vehicle.

The Chemistry behind Fire in Electric Forklift Batteries

One reason a fire extinguisher should be considered a must-have is the significant “fuel” component of an electric forklift. No matter if the warehouse vehicle you use is a TYPHON STOMP or a standard reach truck; it always depends heavily on the battery.

When a battery suffers damage, is on the verge of overcharge or simply is neglected, then the fire resulting from it will be of such a nature that it will not be burned by normal wood or paper methods.

- Lead-Acid Battery Danger: Older batteries are notorious for releasing hydrogen gas while they are being charged. Since the hydrogen is a highly flammable gas, it takes just a spark from a careless connection to ignite the gas, thus a fire extinguisher is the first thing you will need for safety.

- Lithium-Ion Battery Fire Propagation: With modern lithium-ion batteries, there is a potential for thermal runaway, which means the temperature of one battery cell causes another to ignite. While a portable fire extinguisher might not be able to stop the chemical reaction going on inside the battery, it’s an essential tool for preventing the spread of a fire to the rest of the forklift and to the warehouse.

- Dry Chemical Appropriateness: A Multi-Purpose Dry Chemical (ABC) or a CO2 extinguisher is the preferred choice in scenarios like this, this way the electrical current can be safely interrupted, and the flames smothered without conducting the electricity back to the operator.

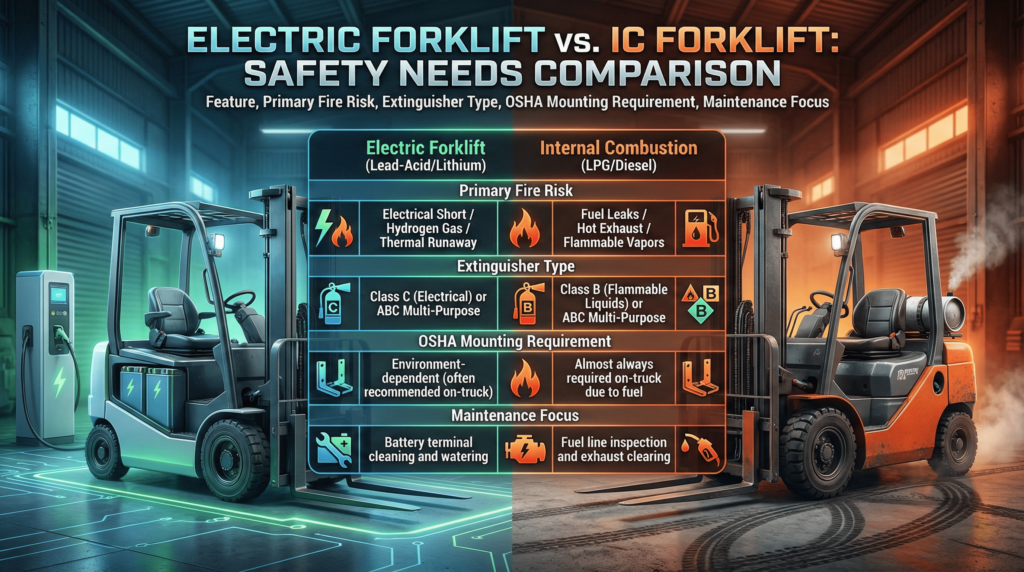

Electric Forklift vs. Internal Combustion (IC) – Safety Needs Comparison

| Feature | Electric Forklift (Lead-Acid/Lithium) | Internal Combustion (LPG/Diesel) |

| Primary Fire Risk | Electrical Short / Hydrogen Gas / Thermal Runaway | Fuel Leaks / Hot Exhaust / Flammable Vapors |

| Extinguisher Type | Class C (Electrical) or ABC Multi-Purpose | Class B (Flammable Liquids) or ABC Multi-Purpose |

| OSHA Mounting Requirement | Environment-dependent (often recommended on-truck) | Almost always required on-truck due to fuel |

| Maintenance Focus | Battery terminal cleaning and watering | Fuel line inspection and exhaust clearing |

Electric Forklift Fire Extinguishers: Best Practices for Mounting and Maintenance

If you make the decision of arming your electric fleet American Forklifts highly suggest you do so as a maximum liability protection measure-the installation of electric forklift fire extinguishers must be done correctly. If the extinguisher is not mounted properly, it can seriously harm the forklift operator during a tipping event, and if the extinguisher itself is neglected, it will not function properly when needed.

- Strong Mounting: A heavy-duty vehicle bracket is required, and it has to be of a type that can endure the shocks and vibrations typically experienced in forklift operations. Do not use zip-ties or store the extinguisher in the cabin in a loose manner.

- Efficient Location: The fire extinguisher should be installed in a way that the driver will not be distracted during an emergency, can easily get hold of the extinguisher, and does not feel obstructed while still monitoring the surroundings or making an escape from the machine.

- Annual Inspections: Simply doing a visual inspection of fire extinguishers monthly is an OSHA requirement. Locating the extinguisher on a forklift, besides checking the expiration date, you should also confirm that the pressure gauge is pointing to the green zone, the pin is in place, and the nozzle is clean and clear of any dust from the warehouse.

Electric Forklift Charging Station Safety Protocols

The greatest risk of fire in an electric forklift arises not when it is in motion but rather during the charging phase. That is because the battery is most stressed and, at the same time, flammable gases are most likely accumulating.

One must not forget that “charging safely” is equally as important as “driving safely” at American Forklifts.

- Extinguisher Stations Which Are Dedicated: Large, wall-mounted Class ABC extinguisher should be within 25 feet of each charging bay and charging unit.

- Air Circulation Systems: Charging area should be well-ventilated to discourage the buildup of hydrogen gas, which is a major cause for flash fires.

- Remove No-Smoking Areas from the List of Negligible Risks: No-smoking, no-sparking rules (e.g., grinding and welding) must be strictly adhered to the area surrounding electric forklift charging stations.

How to Prepare Your Operators for Fires?

Besides their regular training, employees need to know how to handle emergencies too. Ultimately, the extinguisher is only going to be as good a tool as the user of it. Even if the electric forklift has the safest features installed on it, the worker still can panic and do the wrong thing thereby making the situation worse.

- PASS Instruction: Each operator should know and be able to demonstrate the PASS method: Pull the pin, Aim at the base of the fire, Squeeze the lever, and Sweep from side-to side.

- Evacuation Prioritized: Operators are taught that their own safety is their first concern. In case the battery fire is substantial and/or there is plenty of smoke, they should keep a safe distance, call the emergency number and not attempt to fight the fire.

- Emergency Power Cut-off: Operators must be trained on how to cut off the power from the battery quickly (the “emergency disconnect” or “dead-man” switch) to break the circuit to the short.

FAQs – Do electric forklift need fire extinguisher?

Is a fire extinguisher required on a forklift by OSHA?

OSHA only rarely requires fire extinguishers to be carried on machines, although it does make a reference to NFPA (National Fire Protection Association) standards in OSHA 1910.178(a)(2). These standards prescribe extinguishers to be necessary if the truck is an IC model or if the work environment is hazardous. Fire extinguishers needs to be in the vicinity for electric trucks.

What type of fire extinguisher is best for an electric forklift?

Electrical fires must be extinguished by Class C rated fire extinguishers. The most common type of fire extinguisher in a warehouse is a 2.5lb or 5lb ABC Dry Chemical extinguisher which is versatile for a combination of wood/paper (A), flammable liquid (B), and electrical (C) fires.

Why do some forklifts have fire extinguishers and others don’t?

IC forklifts have to carry flammable fuel and this is probably why they have fire extinguishers mounted on them. On the other hand, manufacturers usually don’t equip electric forklifts with fire extinguishers, so it becomes a matter of the employer’s decision F based on the hazard assessment at the workplace.

Where should a fire extinguisher be mounted on a forklift?

One way to mount the extinguisher is on the vertical main post of the overhead guard and the location should not be in the direct line of sight of the operator but should be easy to get to. Never mount your extinguisher in such a way that it gets in the way of the machine controls.

Do lithium-ion forklift batteries need special fire extinguishers?

Standard ABC extinguishers are considered effective for secondary fires caused by lithium-ion batteries, but they do not have the capacity to put out thermal runaway. In such emergencies, huge volumes of water (for cooling the cells) or specialized “Class D” agents may be needed by professional fire fighters.

Can a water fire extinguisher be used on an electric forklift?

Water being a conductor of electricity, one should not use it on an electrified electric forklift battery as it will cause an intense electric shock to the user and the battery may even explode.

How often should forklift fire extinguishers be inspected?

Visual inspection has to be done every 30 days and a technician performs the maintenance once a year. Depending on the extinguisher type, it also needs hydrostatic testing every 5 to 12 years.

Conclusion – A Clarity on – Electric Forklift Fire Extinguisher

That being said, do electric forklift need fire extinguisher? While the electric models enjoy slight leeway in the letter of the law when compared to the propane ones, the general ethos of safety is consistent. Adding a fire extinguisher to your electric forklifts at the cost of a few hundred dollars can greatly enhance the safety of your employees and the protection of your assets. At American Forklifts, we uphold the idea that good safety practices bring efficiency in operations. Thorough battery care, following a charging protocol, and making sure a Class C fire extinguisher is always accessible, these are the measures that will provide for a scenario-proof workplace.