So electric forklift need oil? Electric forklift Hydraulic oil maintenance – Top 6 Features:

It is a widespread misconception that electric forklifts that run on batteries and not internal combustion engines are completely “fluid-free.” True, you won’t have to do traditional engine oil changes anymore, but these devices still require a variety of lubricants and fluids for their safe and efficient operation.

Knowing the exact lubrication requirements of your electric fleet is the right step towards preserving your purchase for a long time and at the same time obtaining the best performance on the warehouse floor. Presented below is an in-depth guide about the oil and fluid requirements for electric forklifts.

Do Electric Forklifts Need Engine Oil?

The single most significant benefit of switching to an electric fleet is the removal of the internal combustion engine. As a result of there being no pistons, valves, or crankshafts to be continuously lubricated against the high-heat combustion, the conventional “oil change” has vanished into the past. Nevertheless, the machine is not maintenance-free.

- No Engine Oil Required: Probably the biggest benefit of an electric forklift is the fact that an electric motor doesn’t use engine oil. This is quite the contrast with a diesel or LPG engine forklift, which in essence is an engine block that needs motor oil.

- Reduced Maintenance Costs: The maintenance costs of your electric-fueled equipment should come down considerably as you won’t have to deal with engine oil, oil filters, spark plugs, etc.

- Environment friendly: electric forklifts when used indoors even have a much smaller environmental footprint as they do not generate waste motor oil for disposal.

Top 6 Features of Electric forklift hydraulic oil maintenance:

1. The Role of Hydraulic Oil in Electric Forklifts

Engine oil is skipped in electric models, yet the use of hydraulic oil is nearly universal among them. This fluid essentially represents the energy source for the lifting gear that is responsible for all fork movements including ascending, descending, and tilting of very heavy loads.

Electrics without a proper quantity of good-quality hydraulic liquid will quickly become a very sum of money placed on paper.

- Lifting Power: The pressure used to operate the cylinders that in turn raise the forks and the load is derived from hydraulic oil.

- System Lubrication: Within the hydraulic system, the oil serves to lubricate the internal seals and pumps, thereby minimizing the wear caused by friction.

- Heat Dissipation: As the hydraulic system operates, it produces heat; the fluid plays a role in removing this heat from the components that are sensitive to overheating.

2. Understanding Differential and Gear Oil

The forklift’s electric motor generates power that must be put to the wheels in order to move the forklift. The transmission or transaxle assembly takes care of that.

Similarly to a car’s gear, these parts need to be greased with heavy-duty gear oil so as to avoid the grinding of metal on metal and the premature wear of the parts.

- By forming a protective layer on the teeth in the differential, gear oil ensures that power can be transmitted smoothly to the drive tires.

- By lowering friction, gear oil makes it so that the electric motor does not need to exert more than necessary, which will lead to a longer battery life.

- Very good-quality gear oil is capable of suspending minute metal particles and debris so that they do not come in contact with the gear teeth until the next scheduled maintenance.

3. Brake Fluid Requirements

The most important thing in any environment where material handling equipment is used is safety. It goes without saying that at the highest level of priority is safety. Electric forklifts mostly run on brake hydraulic systems that function with a specific brake fluid which has to be compatible.

Keeping the brake fluid at the right level and making sure that it is not contaminated is necessary for the power of the brakes to work effectively even during maximum load conveyance.

- Pressure Transfer: Since brake fluid is incompressible, the pressure exerted on the brake pedal is immediately transmitted to the brake pads or shoes.

- Corrosion Inhibition: Nowadays, brake fluids contain additives that prevent the deterioration of the internal parts of the braking system caused by rust and moisture.

- Consistent Performance: A good-quality brake fluid guarantees that the brakes will not “fade” or lose their effectiveness due to prolonged use and frequent stopping during the shift.

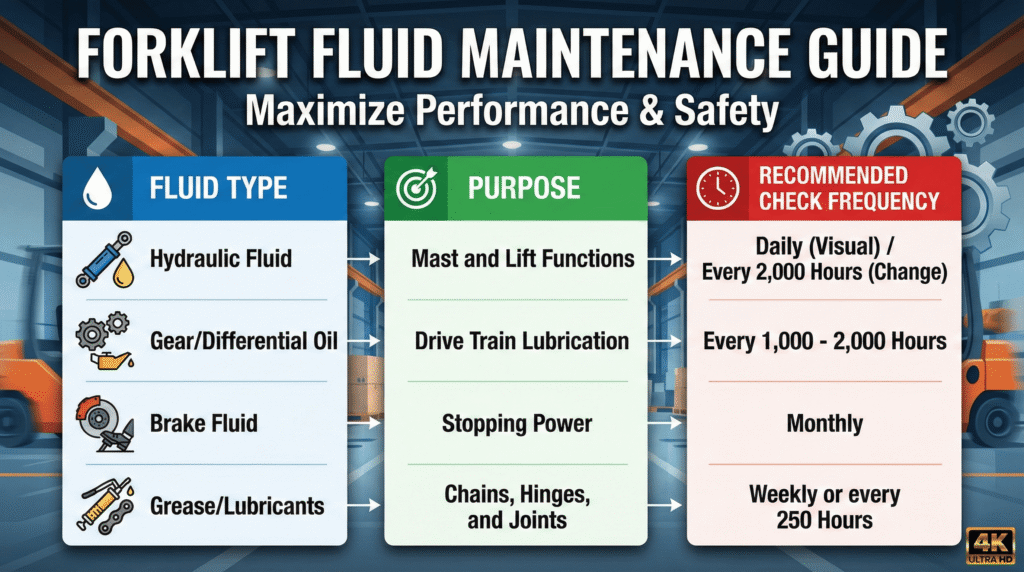

4. Standard Maintenance Intervals for Electric Forklift Fluids

| Fluid Type | Purpose | Recommended Check Frequency |

| Hydraulic Fluid | Mast and Lift Functions | Daily (Visual) / Every 2,000 Hours (Change) |

| Gear/Differential Oil | Drive Train Lubrication | Every 1,000 – 2,000 Hours |

| Brake Fluid | Stopping Power | Monthly |

| Grease/Lubricants | Chains, Hinges, and Joints | Weekly or every 250 Hours |

5. Mast and Chains Maintenance

Completely apart from the internal elements’ fluids, it is exterior components that are moving on an electric forklift and they need to have “stick” lubricants or grease. The leaf chains and the mast channels are literally under force and motion all the time.

The parts that have been running dry for a while will produce such noises that one would actually wonder and the metal will start to flake or “gall.”

- Chain Maintenance: Make sure that you use good-quality chain oil so the links operate smoothly over the sheaves without any kind of binding.

- Mast Slide Greasing: The purpose of putty applied onto the mast rails is to facilitate a smooth movement of the carriage up and down without any jerking.

- Steering Axle Pivot Points: The steering response can be kept at optimal levels if grease is regularly applied to the fittings (zerks) on the rear axle.

6. Battery Water: The “Other” Vital Fluid

The liquid inside a lead-acid forklift battery is not an “oil”, however, it is the most commonly replaced fluid in an electric forklift. The difference between a good battery and a dead one is basically the control over the electrolyte level.

- Stopping Sulfation: The lead plates get damaged when they are not immersed in the water/acid mixture, so by allowing them to stay submerged you prevent the buildup of sulfates.

- Distilled Water Only: Always use distilled water since the tap water contains minerals that result in chemical imbalances, which in turn “short out” the life of the battery.

- Post-Charge Watering: If you are adding water after charging you should always make sure the charging cycle is complete so that the acid doesn’t overflow when it gets heated as a result of charging.

FAQ’s: Electric forklift oil maintenance

Does an electric forklift have a transmission?

It is true that electric forklifts are equipped with a transmission or transaxle that transfers power from the electric motor to the drive wheels. As regular car transmissions, these systems require gear oil for lubrication, except they are devoid of the multi-speed gears usually found in IC forklifts.

How often should I change the hydraulic oil in an electric forklift?

According to most manufacturers, hydraulic fluid should be changed once every 2,000 operating hours. In addition, to keep the fluid clean, the filters should be checked every 500 hours and replaced if necessary.

What happens if a forklift runs low on hydraulic oil?

The mast can move very slowly or the unit may make chattering sounds and fail to lift the max height when there is a lack of fluid. Besides, it can cause the pump to cavitate, thus damaging your hydraulic pump permanently.

Can I use regular motor oil in my forklift’s hydraulic system?

Absolutely not! Motor oil and hydraulic oil differ in viscosity and additive packages. Therefore, using the wrong oil can cause seals to be damaged resulting in system failure. To be on the safe side, always choose the ISO grade recommended by the manufacturer.

Why is my electric forklift leaking oil if it has no engine?

Normally, electric forklifts leak hydraulic oil from the hose, cylinder seals, or differential housing. Any oil found on the floor needs immediate checking as it could cause a safety risk, and the oil leaking parts could fail.

Do lithium-ion forklift batteries need water?

Not at all. The main difference between a traditional lead-acid battery and a lithium-ion one is that the latter is totally sealed and requires no maintenance. You won’t have to worry about watering, equalizing, or cleaning acid spills anymore.

How do I check the fluid levels on an electric forklift?

You can check the hydraulic fluid level via a dipstick or sight glass in most models and typically there will be a hole on the differential where you can check the gear oil as well. Before checking, make sure that the forklift is parked on a level surface and the forks are lowered.

Conclusion – Electric forklift Hydraulic Oil Maintenance Process

Going electric simplifies the maintenance you need to do but it does not make it disappear entirely. All the workers at retail shops, warehouses, and factories especially those who move goods around with forklifts must know at the bare minimum how to keep watch over the hydraulic fluid, gear oil, and grease points at all times to guarantee that their equipment from American Forklifts stays reliable and to not be caught in an unexpected machinery breakdown which, as we all know, is always expensive both in time and money. Furthermore, by sticking to a planned routine maintenance schedule, the quiet, clean, and economical benefits of electricity can be your friends without your favorite electric equipment unexpectedly breaking down.