How Electric Forklifts for Cold Storage is Useful?

Electric forklifts for cold storage have become a must-have in modern cold storage facilities that are spread across the United States — industries that require temperature control, safety, and efficiency, among other things. Nevertheless, a sub-zero environment is a source of a few issues for the machines, especially in the case of their batteries, maintenance, traction, and parts wear and tear.

Electric Forklifts for Cold Storage and Their Use

Electric forklifts for cold storage are the most common and the most necessary means to carry out the works of cold storage and freezer warehouses. The kinds of goods stored can be from the food or the pharmaceutical industry or even just the most sensitive to temperature materials.

Unlike internal combustion forklifts, they make no release, which is welcomed in short-range works where purity of the air and temperature are indispensable. Still, the machines and people whose job is to operate them are put to an endurance test by the temperatures of a scale from zero to minus twenty degrees Fahrenheit.

- Electric forklifts are able to constantly function in closed cold areas since they generate no smoke or heat, which can affect already stored articles.

- They are less noisy and more manageable, thus, the operators get less tired and the overall working hours’ productivity increases.

- The running costs of their operations are notably less than those of gas-powered models, in particular, when energy-conserving charging procedures in temperature-controlled environments are also used.

The performance of the electric forklifts for cold storage has become dependent on the technologically advanced configurations of the forklift battery management system and the sensors that are designed for the stablility of the system in the freezing conditions.

Temperature: The Killer of Electric forklifts for Cold Storage

Temperature has a strong impact on the mechanical parts as well as the electrical components of an electric forklift. The story is as follows: when the ambient conditions are cold, the internal fluids become thicker, the hydraulic systems slow down, and the electrical currents in the battery get weaker. If such a facility is operating continuous shifts, the combined effect of performance reduction can significantly slow the work flow.

- Extreme cold is the main reason of the electrolytes inside lead-acid batteries becoming thick, and as a result, the power output is decreased by up to 40%.

- The hydraulic parts become more viscous causing the lift speeds to slow down and the responsiveness to be at a lower level.

- When forklifts shifting between freezer areas and ambient loading docks, condensation is generated, and it can later freeze and rust the connections.

Therefore, electric forklifts for cold storage should still be able to function within these environmentally compatible limits, as preventive steps such as a heated battery room and an anti-condensation coating being necessary to maintain the time in which they are available for use.

Selecting the Best Electric Forklift for Cold Storage

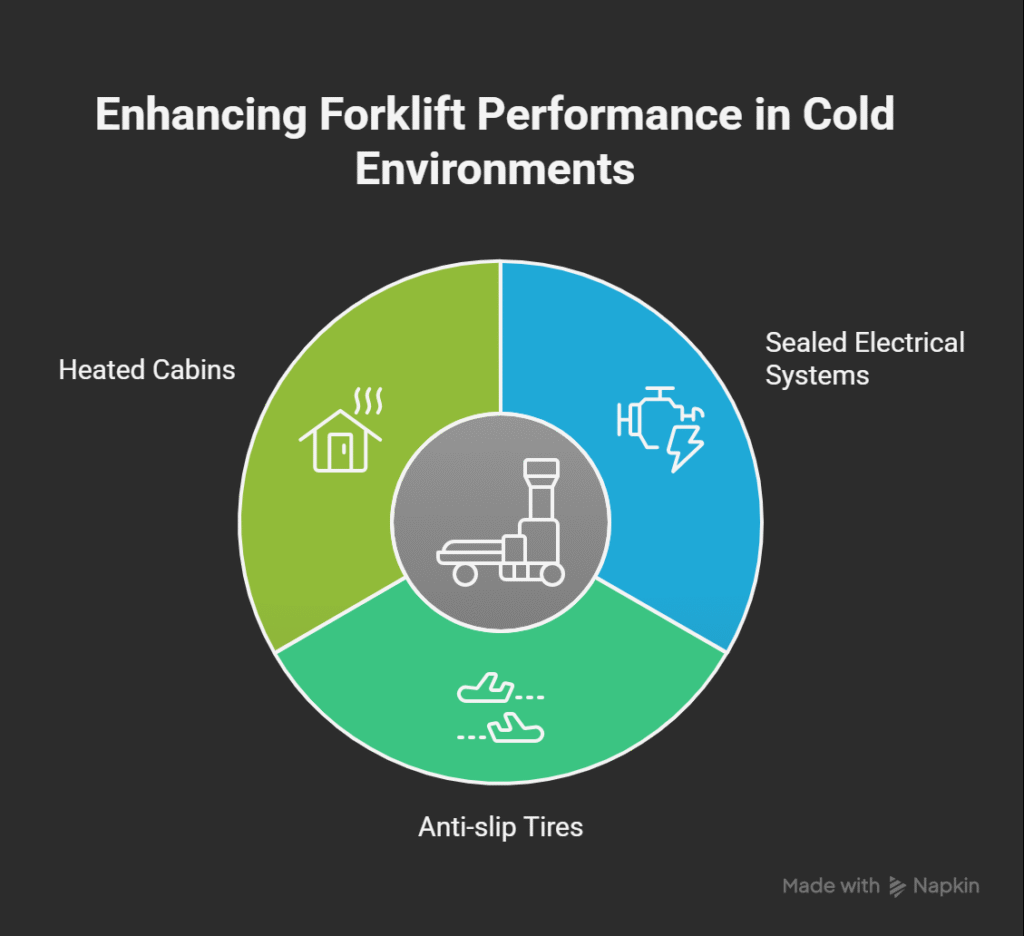

Making the right decision of the suitable forklift model for warehouses with refrigeration or blast freezers is a must. Presently, manufacturers have the “cold-storage package” where they provide insulated cabins, stainless steel parts, and the wiring systems that are sealed.

Table: The Best Electric Forklift for Cold Storage

| Forklift Feature | Cold Storage Advantage | Example Use |

| Sealed electrical systems | Prevents moisture ingress and corrosion | Deep-freeze warehouse operations |

| Anti-slip tires | Improves traction on icy floors | Frozen food storage |

| Heated cabins | Enhances operator comfort | Pharmaceutical logistics |

- Electric forklifts for cold storage that have been designed for extreme cold conditions come along with features such as frames that are galvanized, ball bearings that are sealed, and the finishes that are resistant to the corroding.

- Today, lithium-powered electric forklifts can provide excellent performance even in very cold conditions due to their stable voltage output.

- Make sure that the units have insulated compartments for operators and lubricants that are suitable for use in cold conditions so that the motion and control can be kept at a constant level.

By such model purchasing, the frequency of maintenance is cut down, and the performance is protected in supply chains that are temperature-controlled.

Battery Management in Freezing Temperatures

The most important part of an electric forklifts for cold storage is its battery, and in the case of cold storage, managing that battery is by far the most determining factor of that battery’s uptime and longevity. The very low temperatures discourage the chemical reactions that take place inside the cells, thereby, both the runtime and the device through which the charging is done get less efficient.

- Keep a permanently heated charging spot, a place where the temperature is always above 50°F while recharging is going on.

- Lithium-ion battery technology is far more superior than lead-acid one as it is capable to hold higher voltage even at -4°F and also charging can be done faster.

- Use insulated battery blankets or thermal covers for that time when the battery is left without any work and hours are there so that battery discharge is slowed down.

Implementing battery fleet management systems additionally supports the close monitoring of total usage cycles and the best possible utilization, thus, the system is safeguarded from the capacity loss that cannot be reversed and rust that is caused by condensation.

Maintenance Practices for Electric Forklifts for Cold Storage

The performance of refrigerated warehouses heavily depends on their routine and preventive maintenance. Low temperatures turn materials into a more brittle type and at the same time, the efficiency of the lubrication is lowered, therefore, the premature wear issue is caused. The follow-up of an OSHA safety-compliant method guarantees safety as well as cost efficiency for the given operation.

- Perform daily pre-operation inspections with a focus on fluid levels, tire condition, and mast operation.

- Apply low-viscosity hydraulic oils and cold-rated greases to avoid the hardening of the oil and the lag of the hydraulics.

- Check visually for the ice that has built up on the forklifts or that they may have leaks or the hoses are brittle, and after your shift, remove the moisture immediately.

By being very detailed about the inspection log and at the same time planning their lubrication tasks, the lifespan of a forklift could be prolonged with 3-5 years, as suggested by the Material Handling Equipment Distributors Association.

Operating Best Practices in Freezer Environments

The behavior of the operators is on the same level of importance as the performance of the machines in the cold zones. The safest measures not only lessen the downtimes and the occurrences of accidents, but they also give a hand in the prolongation of the lifespan of the lifting equipment.

- Battery health, tire traction, and fluid lines should be the main points of focus for pre-shift checks that are always carried out.

- During the entire shift, forklifts should be kept in the cold in order to lessen the amount of condensation that occurs due to the change in temperature.

- Operators should be trained in controlling the speed of the vehicle, and when it comes to braking, the distance should be longer especially if the floor is icy.

Moreover, the use of personal protective equipment (PPE) such as gloves that keep the hands warm and boots with soles which do not slip should be ensured, and at the same time, appropriate lighting, as well as the warning systems, should be in place inside the warehouse specifically designed for electric forklifts for cold storage.

Advantages of Using Electric Forklifts for Cold Storage

The conversion from an internal combustion to an electric-powered machine is not simply an environmentally friendly decision but also a functional one. Electric forklifts for cold storage operators are the ones who choose such machines because of their clean operation, less heat release, and controllable performance.

- Keeping the operation with no emissions is what helps the air to stay pure which is the main thing for the perishable products that may be meat or dairy.

- With the fast and on-demand charging that lithium-ion forklifts offer it is possible to have non-stop operations without battery swapping.

The advanced telematics together with the monitoring systems are providing the up-to-the-moment data regarding the battery condition as well as the motor temperature and thus the prevention of the breakdowns is done in advance.

The most significant of these advancements are in line with the green initiatives that are now a part of sustainable warehousing practiced by many logistics companies.

Safety Protocols and OSHA Compliance

OSHA Standard 1910.178 spells out in detail the safety and inspection regulations that are relevant to and should be observed in cold storage operations. If the cold-related equipment failures are not handled in time, they are considered as technical safety hazards.

- Perform the required daily inspections. Make a record of every mechanical and hydraulic observation.

- Take away immediately any piece of equipment with frozen hydraulic lines, corroded connectors, or leaking batteries.

- Keep proper signs and training records to make sure all the operators understand the challenges of working in freezer environments and have the necessary skills to cope with them.

By following the requirements set in these standards, the operators will be able to stop those incidents that have on the average a cost of $135,000 caused by the combination of the companies’ losses due to damages and downtime.

Optimizing Performance Through Technology

Cold warehouses of today are equipped with technologies that make fleet management not only possible but also efficient and easily predictable in terms of performance of the forklifts. Smart sensors, telematics that are connected, and automatic battery monitoring being the causes of the lowering of human errors and of the increasing of the time when the machines are not working due to waiting for service or repair.

- Using telematics, torque, braking, and battery consumption can be observed in various freezer zones.

- Predictive maintenance software is able to locate very early the irregularities in the charging pattern that lead to a drop in performance before they become visible.

- Intelligent chargers regulate the flow of the current depending on the temperature of the battery thus providing the prevention of overcharging and optimising the charge intake.

The aforementioned developments are not only a means for the company to go less expensive on operational issues but at the same time, they help to achieve more strict safety standards that require extreme conditions.

Future with Electric Forklifts for Cold Storage

Electric forklifts are the next generation of logistics that serve cold storage — they are energy-saving, environment-friendly, and are getting more and more dependable due to the modern lithium-ion technology.

But on the other hand, to be able to harness their full power, there needs to be a custom approach among electric forklifts for cold storage in various aspects as in battery management, maintenance, operator training, and environmental control. If businesses follow the correct operational procedures and make use of technology that relies on data, then they can be assured of uninterrupted productivity even in the coldest warehouse conditions.

The information here is in line with the mission of American Forklifts—to provide transparent, expert-backed knowledge to every operator, manager, and buyer thus enabling them to make decisions about forklift selection and operation with confidence.

FAQs on Electric Forklifts for Cold Storage

How cold can electric forklifts for cold storage operate effectively?

An electric forklift for cold storage that is well designed may function efficiently as far as the temperature of the surroundings goes to -20°F but this should be allowed only if lithium-ion batteries are used and the fluids are cold-rated.

Do lead-acid batteries fail faster in cold storage?

Yes, that is true. Lead-acid batteries, in freezing temperatures, might be able to lose up to 40% of their total capacity if there is no adequate heating system or insulating battery covers are used.

Are lithium-ion forklifts better for freezer warehouses?

They certainly are. The efficiency of lithium-ion batteries can be as high as 90% even in very cold environments, and these batteries need no maintenance, plus they are recharged much faster than the traditional lead-acid ones.

How does condensation affect forklift durability?

Condensation that shifts from cold to ambient and vice versa causes the corrosion, mechanical wear, and short-circuiting if the forklifts are not tightly sealed.

Is specialized maintenance needed for forklifts in cold rooms?

Yes, low-temperature lubricants, corrosion-resistant materials, and frequent pre-operation checks are some of the mandatory conditions for keeping up with the performance and safety.

Can using electric forklifts in cold rooms reduce energy costs?

Yes, of course. Electric forklifts that are equipped with energy-efficient charging systems and lithium-ion technology lower the costs of operations and maintenance in the long run.

What safety measures should operators take in freezing environments?

Operators should be checking the forklifts on a daily basis, putting on the proper PPE, following the routes that have been marked, and ensuring that talking is going on in order to be able to prevent senseless situations of crashing in the places that have low visibility due to cooler and are also difficult to navigate.