Fast warehouse operations depend on the right tools being chosen. Pallet stackers and reach trucks both offer many advantages. What sets pallet stackers from reach trucks? To maximise output, warehouse managers and logistics coordinators have to grasp these factors.

Pallet stackers raise and move pallets to help small facilities with tight aisles. Reach trucks shine in reaching high shelves and negotiating larger storage spaces in the meantime. Different machines effect profitability and production. Selecting the right instruments guarantees process effectiveness, safety, and space economy. All set to weigh advantages and disadvantages? Depending on your needs, choose an intelligent warehouse.

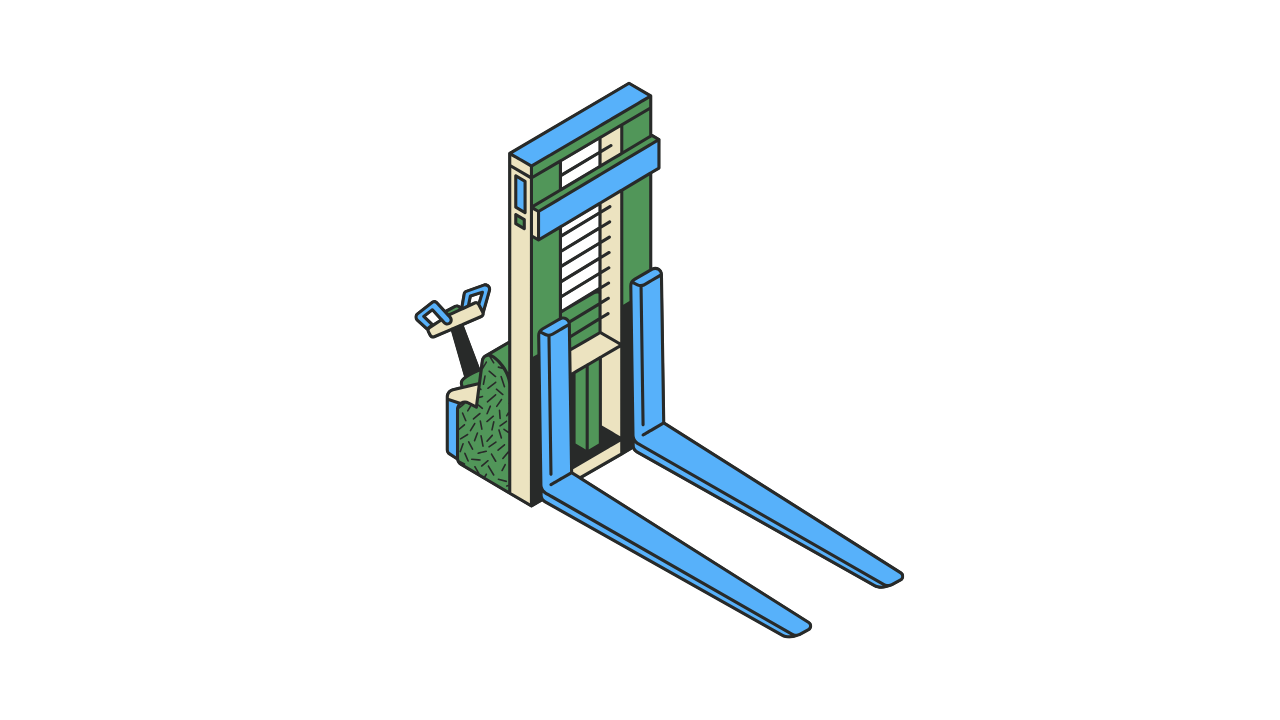

What is a Pallet Stacker?

Pallet stackers lift and stack pallets are among material handling tools. Using a mast and fork system, these single-operator systems move pallets at different heights. Smaller and suited for smaller warehouses or retail areas, pallet stackers are not as flexible as forklifts. Their straightforward, practical approach fits light-lifting jobs.

Pallet stackers classify and arrange goods of limited lanes. Pallet stackers provide smaller passages where larger vehicles cannot fit in highly density facilities. Through control of food product flow, pallet stackers may let supermarket distribution center employees optimize space and order. Pallet stackers are flexible under quickly exact settings.

Simple pallet stacker operation lowers operator required knowledge. Many machines feature basic controls for fast access by new employees. Pallet stackers are preferred by warehouses and smaller budget companies over reach trucks. Low maintenance makes running costs less, hence they are a long-term solution. Companies that need efficient material handling close together without reach truck lifting capability will find pallet stackers appropriate.

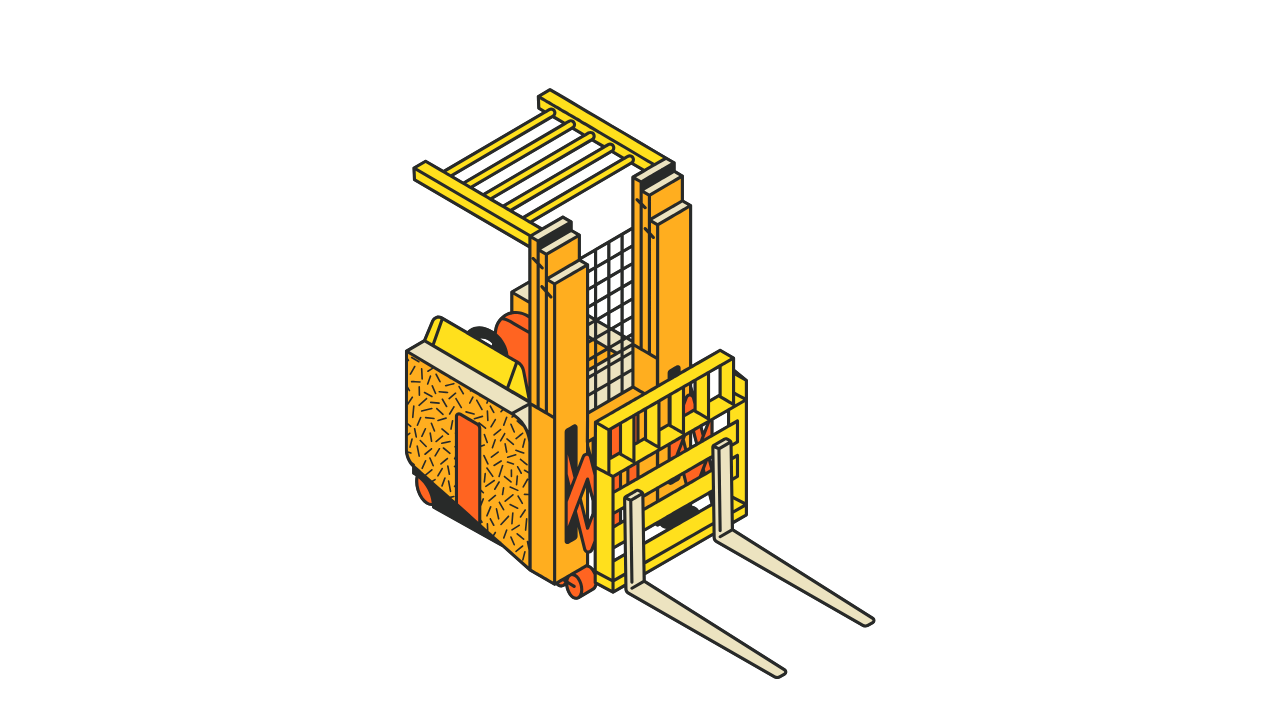

What is a reach truck?

Reach trucks handle narrow-aisle pallets. Reach trucks can stack and retrieve items from large heights because to its long mast, which allows the operator to “reach” forward. The excellent operator vision of these vehicles improves accuracy and safety. Reach trucks are ideal for distribution operations and warehouses that need to optimize space.

Reach trucks reach goods from higher levels in warehouses and transport pallets on high racks. Limited-space operation is very vital in systems with vertical storage-intensity. Reach trucks let beverage distribution facilities access rows of stacked soda boxes, therefore monitoring inventory and optimizing output. This adaptability allows operators to operate inside limited areas.

More than space savings, reach trucks provide are Their computerized steering and load stabilization help to stop tipping. Several types have load weight sensors and height limiters to let employees handle weights securely. For warehouse managers who prioritize safety, reach trucks are fascinating as their stability and creative design increase output and lower mishaps.

Modern warehouses are versatile and so need reach vehicles. Retailers may expand storage without compromising safety or productivity by using their capacity to suit small areas and attain great lift levels. Reach truck value helps supply chain managers and logistics coordinators choose warehousing equipment.

Key Differences Between Pallet Stackers and Reach Trucks

For pallet stackers and reach trucks, design and construction issues matter. Simple pallet stackers lift and stack pallets just because of their simplicity. Front forks let operators raise weights. Modern reach trucks feature longer prongs to access racking systems from farther depths. Their design qualifies them for small areas and high density storage.

Important specifications of material handling equipment include lift height and load capacity. Pallet stackers fit low to mid-level storage as they lift pallets 10 to 15 feet. Using reach trucks to raise thirty feet or more, staff members may swiftly retrieve things on higher racks. Reach trucks can handle 3,000 to 5,500 pounds; pallet stackers run 2,000 to 3,000 pounds.

One further big distinction between these devices is mobility. Pallet stackers’ reduced turning radius helps them to fit in limited warehouse lanes. Their small size enables operators to control tight curves and traffic. Their bigger prongs call for more expansive pathways.

To approach vehicles Though they are less maneuverable in confined locations, reach trucks may be used vertically to boost storage density in larger warehouses and distribution hubs. How different are pallet stackers from reach trucks? By matching equipment capability to operational needs, warehouse managers enhance material handling.

Good Management of Efficient Inventory

Although they have distinct purposes, pallet stackers and reach trucks are very essential for warehouse effectiveness. Popular for its simplicity and ability to control small loads in limited area, pallet stackers Small businesses would find them perfect since their efficiency in loading and unloading pallets from shelves or vehicles. In a small food warehouse, pallet stackers allow things to be quickly transported, therefore saving workers and improving flow.

For high-density storage, reach trucks let bigger objects be lifted. They optimize vertical space and storage by working in fewer aisles. Strict cycle timings in big distribution facilities allow reach trucks to speed retrieval and storage. They help employees reach higher shelves without much floor space, therefore promoting supply chain efficiency.

Energy use is yet another important machine efficiency concern. Reach trucks could use more power as they can lift more than pallet stackers, which do fewer cycles using less energy. Reach trucks allow more products to be transported faster, therefore offsetting their increased energy use. Warehouse managers have to strike a compromise between operational efficiency and energy usage when choosing tools.

Understanding how every tool affects cycle lengths, throughput, and energy consumption helps warehouse operations perform as well as they could. Looking at these elements can help supply chain managers and logistic coordinators make fairly reasonable selections. Aligning tools to operational objectives helps warehouses strike a compromise between performance and resource management.

Manoeuvrability and Storage Solutions

Pallet stackers or reach trucks might compromise efficiency in limited warehouse space. Pallet stackers are meant for lanes and limited areas. Their small scale enables them stack pallets close together for vertical storage without aisles. This benefits tiny, historic warehouses. In high-density warehouses, pallet stackers may go where reach trucks cannot, therefore allowing daily operations greater freedom.

For larger aisles and bigger loads, reach trucks shine. Its lengthy prongs in high-bay storage allow employees to get deep into racking systems. Bargaining for wider aisles of need For larger warehouses needing height and reach for high-value items, a reach truck might be perfect. Knowing the layout of your warehouse guides equipment selection.

Think about how storage arrangements impact these two machines while selecting equipment. FIFO inventory control may benefit from pallet stackers with front pallets that are easily reachable. If your inventory control system requires consistent access to high-up or deep-level items in racking, reach trucks—despite their larger size—are valuable. Apart from a reach truck, what distinguishes a pallet stacker? Key is to know your operational demands and how each piece of equipment matches your warehouse design.

Safety Considerations

Operation of a safe warehouse is essential. Safety aspects of pallet stackers and reach trucks help warehouse workers. Stability controls are included into many modern pallet stackers to prevent tipping and reach trucks with automatic speed reduction from tipping. Most versions employ safety sirens and lights on busy warehouses to let people know when equipment is moving, therefore reducing accidents.

Besides, warehouse safety calls for instruction. Training operators guarantees they can run the equipment and alerts of hazards. Operators of reach trucks and pallet stackers have to load and unload goods in limited areas. Regular refresher courses may help individuals increase their safety and skills, therefore lowering the workplace accidents.

Good risk control systems increase warehouse safety. Frequent equipment inspections would help to guarantee that safety precautions and emergency protocols are followed. Crucially, storage options that maximize available space and guarantee equipment safety have to be included. With large aisles, reach trucks may help to increase efficiency and help to decrease collisions. Through risk management, training, and equipment, warehouses might increase employee safety.

Cost Considerations – Problems With Financial Cost

Warehouse managers and logistics coordinators have to choose pallet stackers or reach trucks based on pricing. Starting with different prices, these two types of equipment Less expensive than reach trucks, pallet stackers appeal to companies on a tighter budget. While improving operations, leasing or borrowing forklifts may help businesses save money.

Your decision should also be affected by maintenance costs. Pallet stackers need less maintenance than reach trucks because of their simpler construction and smaller moving components. Whereas pallet stackers only six months, reach trucks may need quarterly inspections and maintenance. If reach trucks live longer and perform better under pressure, they can carry larger loads and work in more demanding conditions, hence justifying their higher price tag.

Studies on total cost of ownership find lifetime equipment expenses. It includes energy, insurance, buying, maintenance, and downtime. By balancing its higher initial cost in warehouses with limited lanes, an operationally effective reach truck may increase productivity. If your company stacks pallets at lesser heights, a pallet stacker may save you money on purchase and maintenance.

Making a smart choice calls for understanding the cost of every tool. Stretch trucks or pallet stackers? To decide which meets your operational needs and budget, weigh initial investment, upkeep, and total cost of ownership. Analyzing these elements reveals your long-term worth and efficiency of choosing.

Making the Right Choice for Your Warehouse

The usage of pallet stackers and reach trucks guide their selection. Everything from the smallness of pallet stackers to the flexibility of reach trucks was investigated. Operations in a warehouse might change depending on major lift height, load capacity, and mobility adjustments. Though all solutions have advantages, the best one will rely on your needs.

Choose a pallet stacker or reach truck keeping in mind operating needs, product types, and warehouse layout. This thorough analysis will assist you in selecting tools to increase output, safety, and efficiency. Spending time on this decision helps outcomes and simplifies logistics.