Forklifts are some of the most prevalent types of construction equipment. They may be used to move a lot of different kinds of materials. But using one can be deadly, especially if you don’t observe safety rules.

Before utilizing a forklift, the operator should check it every day. The Occupational Safety and Health Administration (OSHA) of the U.S. Department of Labor says that forklifts must be checked every day.

Checking forklifts keeps workers safe and helps find maintenance problems before they become dangerous. We give you some simple safety checklists for any kind of forklift in your company in this post.

Why It’s Important to Conduct Forklift Safety Checks

OSHA says that all motorized industrial trucks must be checked for safety before they are used, according to standard number 29 CFR 1910.178(q)(7). This means that before utilizing a forklift, the operator must check it to make sure it is in good working order. If the forklift is used both day and night, it needs to be checked after each shift.

If an inspection finds anything that could impair how well a forklift works, it shouldn’t be used. A qualified mechanic must fix all issues and report them to a supervisor right away.

You should check a forklift before you use it for the following reasons:

- It makes sure that the forklift is safe to use, which keeps operators and workers from getting hurt or having accidents.

- It cuts down on project downtime by finding out ahead of time which equipment requires repairs.

- Taking care of your equipment properly will make it last longer and make it worth more when you sell it.

How to Conduct a Daily Forklift Safety Inspection

There are two main safety tests that need to be done before using a forklift:

- A visual check before you start the engine

- An inspection of the engine while it is running

You should read the operator’s manual for your specific forklift because there are many different types of forklifts and vehicles might be different from one manufacturer to the next. Just like when you use the machine, you should don the right personal protection equipment (PPE) before you start an inspection. This includes a hard hat, safety boots, safety glasses, and safety gloves.

It could seem like a lot of work to complete daily safety checks, but they don’t have to be long or hard. These forklift inspection checklists will help you with every step of your examination.

All Forklift Trucks

When you look at a lift truck, make sure that

- There are no leaks, and all of the fluids, such as engine oil, water, coolant, and hydraulic fluid, are within safe levels for the type of forklift.

- There are no apparent problems, such as dents, cracks, or broken parts, that would cause physical harm or too much wear.

- The hydraulic hoses are hooked up correctly.

- The strain on the mast chain is good.

- The tires are in good shape; they don’t have any cuts or gouges, and the air pressure is right.

- All of the forks are in good shape and are securely fastened.

- All of the devices, such as the overhead guard and the roll over protection structure, are in place and working well.

- All safety signs, such as nameplates and decals, are up and easy to read.

- The operator’s compartment is clean, and all of the controls operate.

- The operator’s manual is inside the truck and you can read it.

- The seat is locked in place, and the seatbelt is working well.

Electric Forklifts

For electric forklifts, also make sure that:

- All cables, connectors, and battery restraints are in good condition and there are no exposed wires.

- Electrolyte levels in the battery are adequate. (Remember to wear PPE when checking this.)

- The hood latch works properly.

Internal Combustion Forklifts

Also, be sure that for forklifts with internal combustion engines:

- There is enough oil, coolant, and brake fluid.

- The radiator and air filter are both working well.

- All of the belts and hoses are in good shape and work as they should.

- The latch on the hood works fine.

Liquid Propane Forklifts

Also, for internal liquid propane forklifts, make sure that

- The tank is in the right place, with working constraints, and the pressure relief valve is pointed up.

- All of the hoses and connectors are in good shape.

- There are no dents, cracks, or leaks that can be seen on the tank.

- The truck fits the tank well.

Operational Inspection Checklist

When you’re done with the pre-operational inspection, you should do the operational check, which is done while the engine is running. This list of things to check applies to all kinds of forklifts.

Check that all of these parts of the forklift are working right:

- The horn, all the indicator lights, and all the alarms, including the backup alarm

- The accelerator, steering wheel, and foot brakes

- The brake for parking

- The gears for going forward and backward

- All of the hydraulic controls

- All the accessories for forklifts

- All limit switches

You can listen for strange noises or vibrations emanating from the machine while it is functioning. You should tell your boss right away if you see any.

Safety Considerations During Operation

It’s a good idea to check the car before you use it to make sure it’s safe, but problems can sometimes happen while you’re using it.

Always be on the lookout for problems while you work, such as:

- The exhaust from the forklift producing sparkles or flames

- Any part of the forklift that gets too hot to work normally

- Leaks that show up

- Mechanical failures or obvious flaws

If you see any of the above while driving a forklift, you should stop the vehicle and get help right away, as required by OSHA standard 29 CFR 1910.178.

Long-Term Forklift Truck Maintenance Checks

You should examine your forklift every day and also take care of it over time, because problems might happen from constant use and wear.

For new forklifts, manufacturers suggest the following long-term maintenance checks:

- A service every 250 hours of use for small repairs

- Every 500 hours of use (approximately every three to six months), you should get a service for intermediate maintenance.

- A major maintenance service every 2,000 hours of use (approximately once a year)

The following lists give an overview of the most important maintenance that needs to be done throughout each of these time periods.

Minor Maintenance (250 hours)

Check that you do the following every 250 hours of use:

- Change the oil and the filter for the oil.

- Change or clean the air filter and the engine cooling system.

- Check the drive belt

- Make the bolts on the cylinder head tighter.

- Change the ignition timing and the speed of the engine when it is idle.

- Tighten the nuts on the hub and wheel.

- Clean and oil the chain, frame, and mast.

- Put oil on the steering and driving wheels.

- Change the filter in the transmission

- Add more brake fluid

These small maintenance activities are usually easy to do, but they have a big effect on how well the forklift works.

Intermediate Maintenance (500 hours)

Every 500 hours, make sure you do the following intermediate tasks:

- Replace the fuel filter

- Change the clearance on the valve

- Change the spark plugs

- Get rid of the water separator and clean the radiator.

- Change the hydraulic filter

- Check the tension of the test chain lift.

These maintenance chores should be done along with the ones that were already done.

Major Maintenance (2,000 hours)

Finally, in addition to the small and medium maintenance checks, you should do the following large inspections every 2,000 hours:

- Change the coolant

- Replace the water separator and fuel strainer.

- Change the gasket seal and the distribution belt.

- Replace or clean the filter for the inside air.

- Change the lubricant on the wheel bearings.

- Change the oil and filter in the transmission.

- Change the oil in the hydraulics

- Switch out the brake fluid

These significant maintenance inspections take the most time and are the most thorough, but they are necessary.

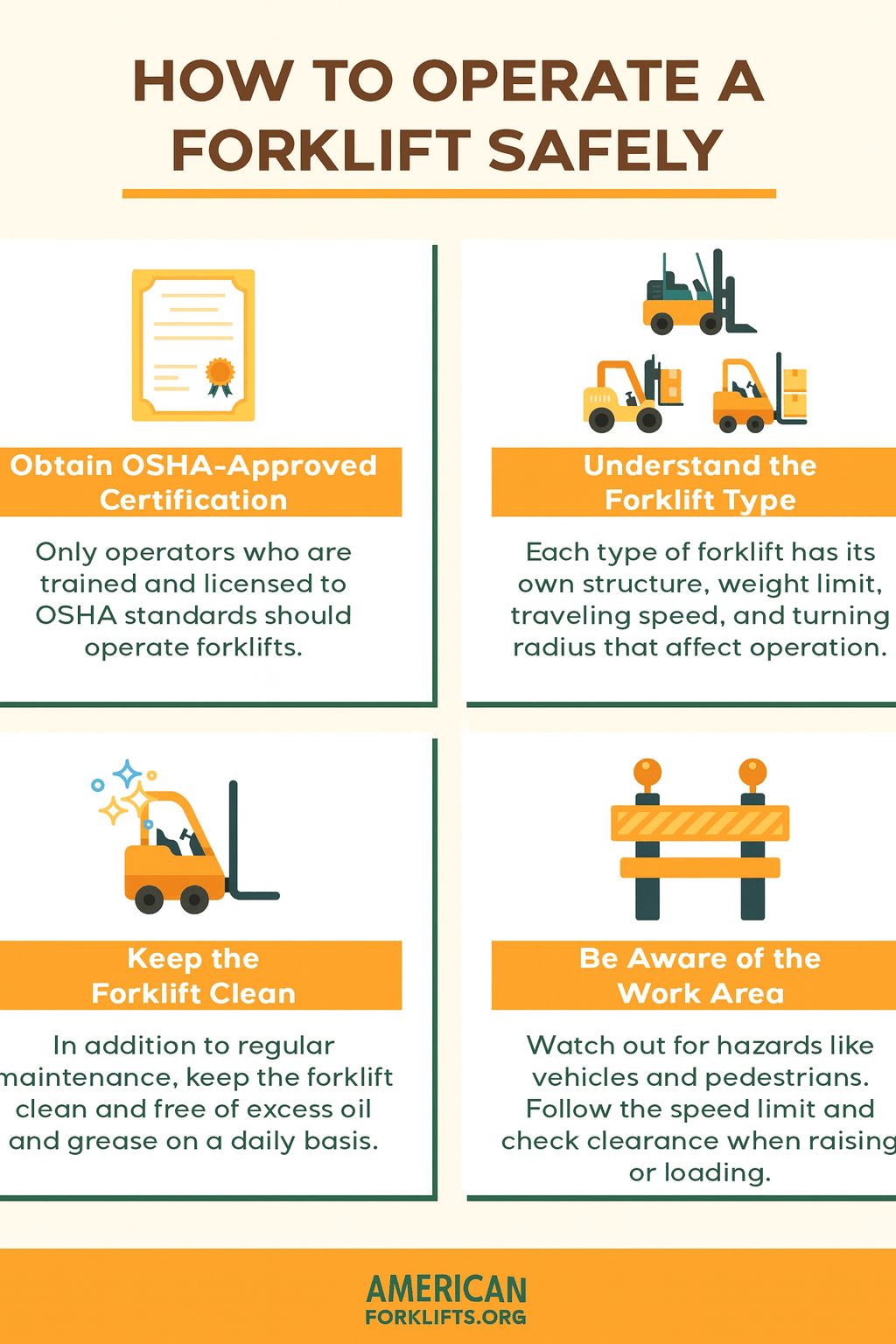

How to Operate a Forklift Safely

How expertly you drive the forklift and how attentive you are of your surroundings are both important for safety. Here are some tips to make sure you use your forklift safely at work.

1. Get certified by OSHA

Forklifts should only be driven by those who have been trained and are licensed by OSHA. This not only keeps the operator safe, but also everyone else on the site.

Different states and types of forklifts have different OSHA regulations, so make sure to find the right ones for your scenario.

2. Know what kind of forklift you have

Make sure that you or your team are thoroughly trained to use the type of machine you have at all times.

The structure, weight limit, speed, and turning radius of each model of forklift are different, which makes a big difference in how the vehicle can be operated.

Also, when fixing or taking care of your forklift, be sure to follow the manufacturer’s instructions and suggestions. Small variances that you might not notice can change what needs to be done.

3. Clean the Forklifts

Every day, oil and grease can build up and make it harder for the forklift to operate and make it less safe for the operator to use the controls. You might not know there’s a problem until it’s too late.

People frequently forget how important it is to keep their machine clean, but it’s just as important for the long run as taking care of the engine and pieces like the mast.

4. Know the area where you work

The forklift isn’t the only thing that could be dangerous on your job site. Be mindful of what’s going on around you. When you use your forklift, be careful of things like:

5. Vehicles that are not yours

When raising or loading, be sure to give people enough room.

A lot of accidents happen because drivers are focused on their cars and not on what’s going on around them.