Logistics, the warehousing and manufacturing sectors – all moving at lightning speed – are no longer treating equipment as just a simple tool. What used to be a piece of machinery, has now become an essential asset with Forklift Fleet.

Out of all, your forklift fleet is the one that follows through the operating easiness, the safety measures, and the stability of the business in the long run. In case your company is still working with old and asthenic forklifts, the expense of not updating is gradually consuming your profits and giving you a headache of falling behind in the market.

Update is not only switching old machines for new ones—it is the complete revolution of your operation with the latest technology, more speed, greater safety and less fuel consumption.

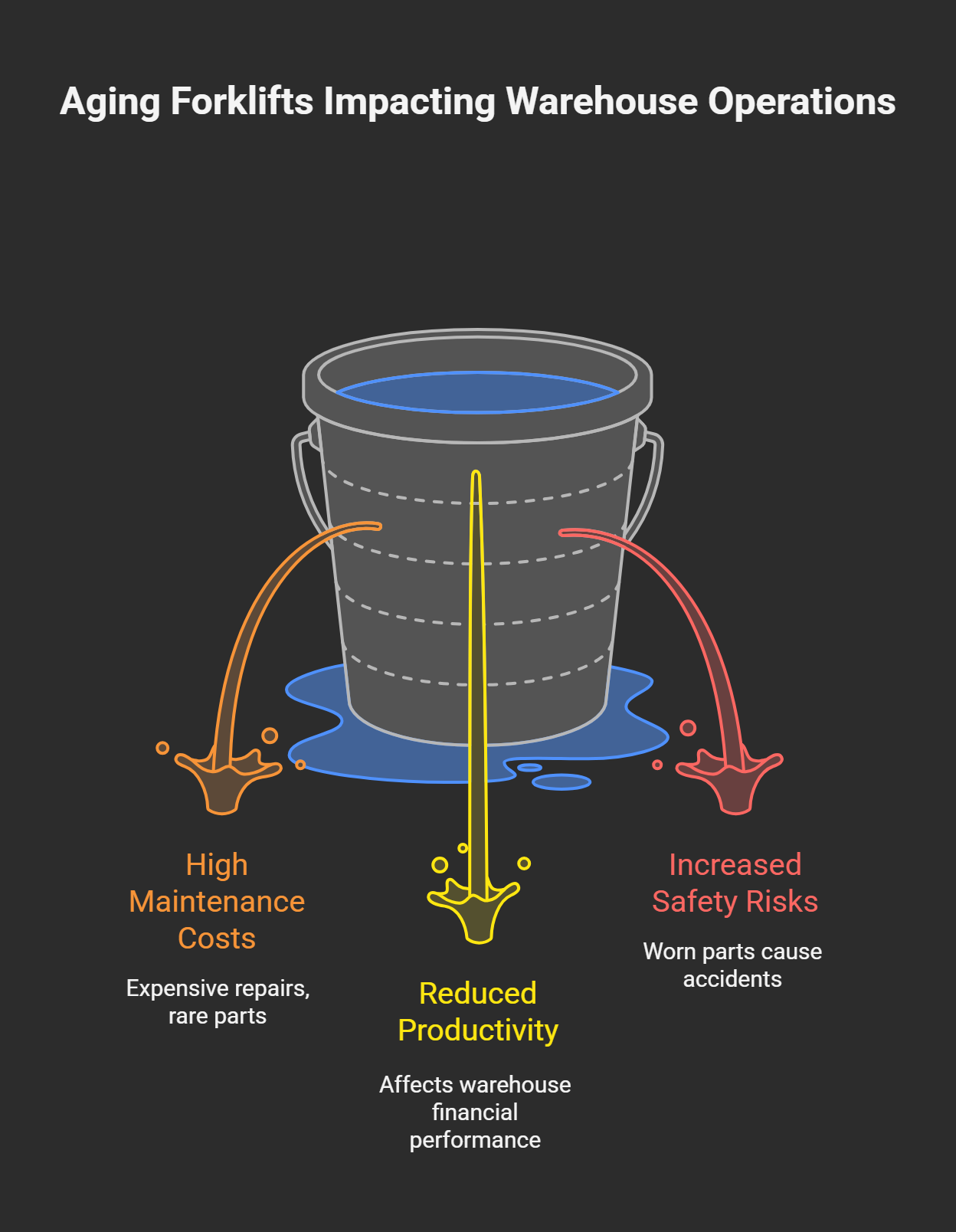

The High Cost of Outdated Forklifts Fleet

Old forklifts and high maintenance costs probably seem like the best way to keep money in the till but this is one of the shortest routes to the loss of a company’s operational capabilities. These former machines are usually prone to break down, expensive to take care of by regular maintenance, and less fuel-friendly.

- Greater maintenance costs: The old forklifts deteriorate to the point of breakdown as they age, and this implies consuming expensive and rare spare parts to undergo maintenance.

- Less productivity: Lack of timely performance affects the process which leads to payback of the overall financial capital of the activity of the warehouse.

- Dangerous risks: The worn-out parts and outdated technology that becomes harder over time in combination with environmental factors propose by these causes the raising of the accident risk.

| Factor | Outdated Fleet | Upgraded Fleet |

| Maintenance Costs | High | Low |

| Fuel/Energy Efficiency | Poor | Optimized |

| Operator Safety | Risk-prone | Enhanced safety features |

| Productivity Levels | Sluggish | Streamlined |

Safe Substantial Changes of Workplace and Compliance

The safety of the staff at the workplace is not something that can be bargained for. Only one case of a forklift accident may result in the victims getting severely hurt, a fine imposed by the Occupational Safety and Health Administration, and bad will. However, the latest models of forklifts come with various safety features, including backup alarms, load stability sensors, automated speed controls, and ergonomic seating.

- Minimize operator fatigue with the use of ergonomic designs that encourage correct posture and comfort of the user.

- Help safety in being done with the use of a smart load stability system and sensors that are embedded and implemented.

- Make attaining regulatory compliance a breeze with the help of these modern, emission-compliant engines, and protocols in safety.

If on the other hand, you only consider the use of older models which do not have these features, then you are taking a great risk of being exposed to liabilities and also facing penalties from OSHA.

1. Improve Operational Efficiency and Throughput

By upgrading to a forklift fleet, a warehouse or logistics operation becomes not only faster but also leaner and more responsive. Times are hard in today’s supply chain, where every moment is valuable. A forklift that performs a sequence of quick lifts, fast moves, and handling of heavy loads will grant you a competitive advantage at the snap of a finger.

Turn on the Green Light for More Efficiency and Throughput:

- Improved hydraulics and digital controls will help you in faster load times.

- You can extend the operating hours of your batteries by using energy-efficient ones or you can just go for the advanced internal combustion engines.

- By integrating telematics and using real-time tracking systems you may expect intelligent routing.

- Installing modern equipment will give your company the advantage of the necessary flexibility and the performance edge to meet the new logistics requirements.

2. Reduce Long-Term Ownership Costs

One of the best investments that can be made is the purchase of a forklift. Relying solely on old equipment, albeit seemingly practical at first, will be costly due to the rapid growth of hidden costs. The upgraded forklifts are much more efficient, and they if they break down less, plus work productivity is higher, then this fork brand leads to a very high return one has to call it a fuel-saving, long-term side of the ROI story.

- Energy cost will be significantly lowered through the usage of electric or hybrid forklift models.

- There will be less unscheduled maintenance and the time lost due to machine stoppage will be reduced accordingly.

- With good quality construction and valuable data on forklift intermediate usage, the service life of the equipment can be extended.

| Cost Category | Old Forklifts | New Forklifts |

| Annual Maintenance | $6,000 | $1,500 |

| Downtime Loss (per year) | $10,000+ | <$2,000 |

| Fuel/Energy Cost per Year | $5,500 | $2,000 |

3. Stay Ahead of Your Competitors

In a saturated market, agility and operational speed are the qualities that set apart the leaders from the rest. A modern forklift fleet can be your secret weapon for customer satisfaction and supply chain dominance.

- Faster deliveries mean happier clients and you get repeat business.

- Flexible handling of diverse inventory gives you the possibility to adjust to changes.

- Future-proof infrastructure will support automation and the use of warehouse robotics.

Your competitors are not waiting—and neither should you.

4. Leverage Smart Technology & Telematics

Today’s forklift upgrades are not just mechanical—they’re digital. IoT-enabled fleet management, GPS tracking, and load analytics are a few of the smart forklifts that turn data into decisions.

- Track usage patterns and predict maintenance needs that can be done with telematics.

- Monitor driver behavior in order to enforce safety and increase productivity.

- Integrate with WMS/ERP systems for the ease of inventory and operations management.

- Smart forklift technology is not something that is going to happen in the future but it is the present.

5. Boost Employee Morale and Retention

Workers are more efficient, better in spirit, and safer in their work when they have access to modern machine which is up to standard. In this regard, no one desires to be surrounded by slow, outdated, and uncomfortable forklifts.

- Ergonomic controls not only lessen exhaustion but also the number of injuries caused by musculoskeletal disorders.

- Digital dashboards ease the operation and training time is cut in half.

- The trend towards quieter engines is one among the several factors that contribute to the rise of the quality of the work environment.

- You are doubly investing in your fleet and your staff when you put money into it.

6. Prepare for Sustainable Operations

Sustainability is not just a matter of choice anymore. There are tight environmental regulations, and customers are looking for conscientious logistics partners. Revamped forklifts are your weapon for lowering your carbon footprint.

- Convert to electric ones that create no emission on the site.

- Apply energy regeneration features in cases of braking or load lowering.

- You may also be eligible for environmental credits or grants, tax-wise, if you meet environmental standards.

Sustainability in every sector, on top of everything, shapes your reputation and brings you in line with global trends.

FAQs on Forklift Fleet Upgrades

How do I know it’s time to upgrade my forklift fleet?

If you are going through the following situations: frequent breakdowns, increasing maintenance costs, slow operations, or safety issues, then you need to upgrade your forklift fleet. Generally, most forklifts should be replaced after 8–10 years of service or even earlier if they have been heavily used.

Is it better to lease or buy new forklifts?

Both options have the potential of being advantageous. Leasing provides the benefits of a lower initial payment and flexibility, on the other hand, purchasing gives the possibility of saving in the long run. It is a matter of your financial situation and the company’s needs that will help make the decision.

Are electric forklifts worth the investment?

Definitely. Electric forklifts consume less energy and thus fuel costs are lowered, in addition they do not emit harmful gases and also emit less noise, and the maintenance part is also less time-consumig. In other words they are worth every penny to be paid for these factors not to be harmed and be a part of green initiatives.

What is the ROI of a forklift upgrade?

The exact amount of money earned back through the forklift upgrade varies a lot from one business to another but in most cases, businesses recover the investments they made, as they achieve higher productivity, and encounter less machine failures and maintenance, within the space of 1 to 2 years, hence the payback period is 1-2 years.

Can I upgrade only part of my fleet?

Yes, doing a fleet makeover by phases is a common method. You can start the process by taking out the oldest or most problematic units and at the same time, replace them with new ones to progressively switch without operations being disturbed.

Are new forklifts compatible with my current warehouse systems?

The new forklifts are generally equipped with software or hardware that allows for seamless integration with Warehouse Management System (WMS), Enterprise Resource Planning (ERP), and telematics. However, it is always a good idea to check if the current system will be compatible with your new forklift before making a purchase.

How does upgrading affect insurance and compliance?

A new forklift typically results in lower insurance premiums for the owner and also makes it less of a hassle to comply with the government rules as the product is equipped with safety and emission features that are environmentally friendly.

Final Thoughts: Upgrade Now, Reap the Rewards

It’s way more expensive than you think when you decide to postpone the upgrading of your forklift fleet. The true cost of an old fleet is disguised in daily inefficiencies and long-term liabilities that gradually drain your money without you realizing it. By being upgrade-oriented, you are putting your money into:

- Operational efficiency

- Employee well-being

- Customer satisfaction

- Sustainability

- Bottom-line growth

Outdated equipment should not be the reason why your business cannot grow. The future of warehousing and logistics are smart, safe, and sustainable, which is just the beginning of a forklift fleet upgrade.