How Are Forklifts Different from Automobiles

Knowing the major differences between forklifts and cars is basic not only for the safety and efficiency of the work process but also for those individuals or organizations that are thinking about the training, the ownership, or the compliance requirements. Although both may look somewhat similar—with four wheels and steering—they are completely different in their fundamental design and take very different approaches.

1. Core Purpose and Design

- Forklifts are heavy-duty vehicles of the industrial category that are built to move, carry, and even place the heavy load of the company, generally in the warehouse, construction, or logistics area. Hydraulics with forks at the front are fitted to move cargo and also to handle it easily.

- Automobiles (cars) are personal or commercial vehicles that are mainly designed for the transportation of people and small packages over public roads. The goal of the technology lies in the aspects of speed, comfort, and road safety.

2. Steering and Control Mechanisms

- Rear-Wheel Steering: Forklifts have rear-wheel steering almost in all cases which is very helpful because it allows a smaller turning radius which is very important when one is driving through narrow aisles or in a heavily packed warehouse. Moreover, the energy or the power can be felt on the other side for the employees who are used to steering in front immediately after their car has turned.

- Front-Wheel Steering: Automobiles, conversely, have front-wheel steering for a more stable and controllable drive at higher speeds.

3. Stability and Center of Gravity

Forklifts

They feature a high and variable center of gravity, which is very noticeable in the case of a loaded forklift. The combination of raised loads and the uneven distribution of the load causes the machine to be subject to tipping over, so operators must keep their travel speed at a minimum and comply strictly with load capacities and positioning rules. Designers deal with the issue by adding weight (counterweight) to the rear of the forklift and furthermore they always keep the maximum speed at a low level.

- Have a high and a variable center of gravity, which is very noticeable in the case of a loaded forklift. The combination of raised loads and the uneven distribution of the load causes the machine to be subject to tipping over, so operators must keep their travel speed at a minimum and comply strictly with load capacities and positioning rules.

- Designers deal with the issue by adding weight (counterweight) to the rear of the forklift and furthermore they always keep the maximum speed at a low level.

Automobiles:

- Come with a low and evenly distributed center of gravity, which is the primary factor for car stability and safety at higher speeds.

- Come with a low and evenly distributed center of gravity, which is the primary factor for car stability and safety at higher speeds.

- Forklifts are obstructed to see in front of them by the mast, forks, and cargo. This creates significant blind spots. Operators are dependent on mirrors and careful maneuvering to avoid accidents.

- Cars have generally better surroundings visibility, easy lines of sight, and less operational blind spots.

Weight: Forklifts usually weigh more than passenger cars because of their construction and the need for extra counterbalancing. The weight of a rough terrain model can be several tons.

Agility: While cars are made to be agile and fast, forklifts concentrate on load stability and, therefore, are less agile, require more space for turning and stopping safely.

6. Operational Environments

Forklifts:

Are found mostly in warehouses, docks for loading, construction sites, and other areas that are closed off for access. Some are designed for tough outdoor places where they have heavy-duty tires and better suspension. They are on surfaces such as concrete, gravel, or even terrain and have to steer clear of hazards such as narrow aisles, dock edges, and tight corners.

- Are found mostly in warehouses, docks for loading, construction sites, and other areas that are closed off for access. Some are designed for tough outdoor places where they have heavy-duty tires and better suspension.

- They are on surfaces such as concrete, gravel, or even terrain and have to steer clear of hazards such as narrow aisles, dock edges, and tight corners.

Automobiles:

- Are made to drive on public roads, highways, and urban/interurban areas. The main focus is on obeying traffic rules and changing road conditions.

- Are made to drive on public roads, highways, and urban/interurban areas. The main focus is on obeying traffic rules and changing road conditions.

7. Driving and Safety Requirements

-

- Must need special training and a certificate (and sometimes have to get it again). Strict safety rules encompass how to use the equipment correctly, what loads it can handle, inspections before use, and personal protection gear.

- Tip-overs, hitting pedestrians or objects, and load spills are all safety issues.

Automobile Drivers:

- You need a driver’s license and some basic knowledge of road safety. You could need extra certificates to drive a business vehicle, but not to drive a regular car.

8. Maintenance and Power Sources

- Forklifts work in tough environments where they are often exposed to dust, debris, and possible accidents. Because of this, their hydraulics, safety features, tires, and batteries need to be checked often.

- Power Sources: Forklifts can run on gasoline, propane, diesel, or electricity. Electric models are best for inside use because they don’t produce any pollution. Cars mostly run on gasoline, diesel, or more and more electricity.

9. Attachments and Functional Flexibility

- You may add clamps, rotating forks, side shifters, and other modifications to forklifts to make them better for certain industrial applications.

- Cars are not made to handle these kinds of changes.

10. Speed and Performance

- Forklifts: Usually only allowed to travel slowly for safety reasons; speeding up or moving quickly could make the truck and its load unstable.

- Cars: Built to go significantly faster and respond quickly and safely to the needs of road travel.

11. Regulatory Environment

- Forklifts are only allowed to be used in certain ways by occupational safety authorities. They need to train their operators, keep their forklifts in good shape, and undertake extensive safety checks.

- The main reasons for regulating car use are safety on the roadway, emissions, and insurance.

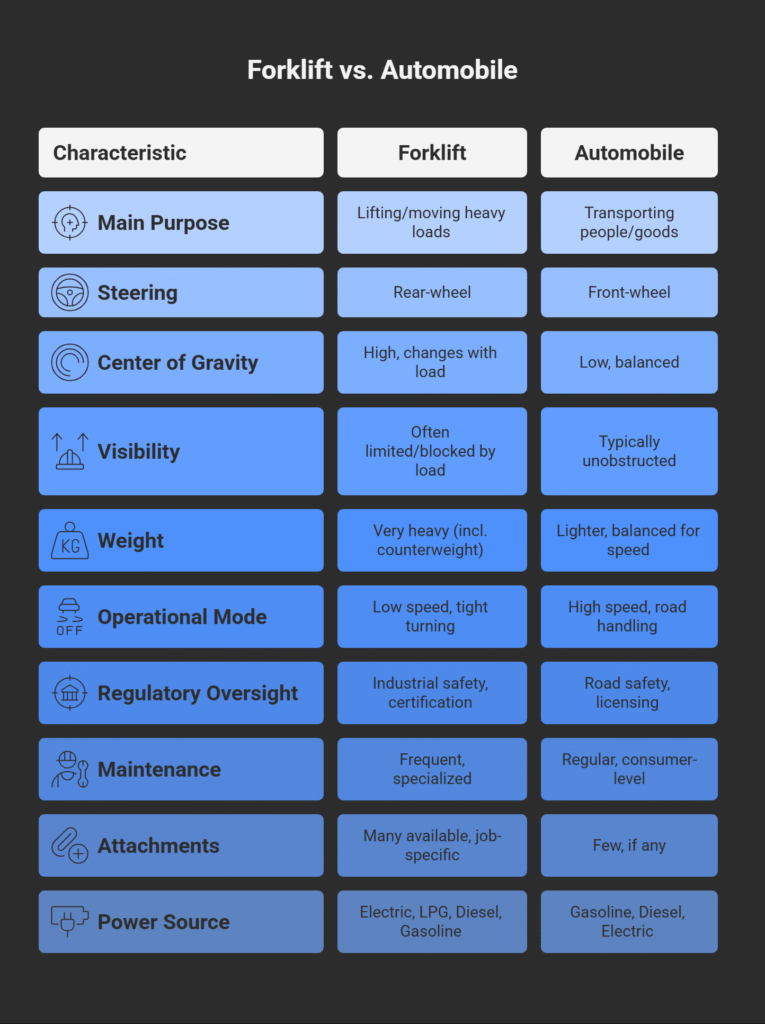

12. Visual Comparison Table

| Feature | Forklift | Automobile |

|---|---|---|

| Main Purpose | Lifting/moving heavy loads | Transporting people/goods |

| Steering | Rear-wheel | Front-wheel |

| Center of Gravity | High, changes with load | Low, balanced |

| Visibility | Often limited/blocked by load | Typically unobstructed |

| Weight | Very heavy (incl. counterweight) | Lighter, balanced for speed |

| Operational Mode | Low speed, tight turning | High speed, road handling |

| Regulatory Oversight | Industrial safety, certification | Road safety, licensing |

| Maintenance | Frequent, specialized | Regular, consumer-level |

| Attachments | Many available, job-specific | Few, if any |

| Power Source | Electric, LPG, Diesel, Gasoline | Gasoline, Diesel, Electric |

Key Takeaways and SEO Summary

- Forklifts are special vehicles used in factories. They are very different from cars in terms of design, function, steering, safety standards, maintenance, and the environment in which they operate.

- Automobile concepts: Front-wheel steering, rapid speed, and easy maintenance are all things that don’t apply to forklifts.

- Safety: Forklifts are quite dangerous because they can topple over and the loads they carry can change. There is no room for negotiation when it comes to proper certification and frequent inspections.

- Operational flexibility : Forklifts have a lot of different load-handling attachments that make them more flexible in terms of how they can be used. However, this means they are slower and harder to handle.

- Knowing these differences helps organizations and people pick the correct equipment, stay in compliance, and keep high safety standards in a wide range of transportation, logistics, and industrial settings.