Why More Warehouses Are Switching to All-Electric Forklift Fleets?

Escalating consumer and legislative demands for environmentally friendly and safer supply chains have caused a large number of warehouses and logistics centers worldwide to make the decision to convert their fleets of forklifts to electric ones.

The main reasons for the change in law, the ongoing development of electric forklift technology, and the rapid change of market priorities are the main reasons that most warehouses in North America and other parts of the world opt for electric forklift fleet. The biggest warehouses, which are the most visible leaders of this widespread electrification, are the first to show the trend of going electric first.

The Rising Trend: Why Warehouses Are Switching

It is predicted that by 2025, more than 70% of new forklift sales will be electric. This is mainly due to stricter regulations, lower ownership costs, and the trend towards zero-emission operations in closed warehouses. Top fleet operators point out that the transition from the old to new technology is mainly driven by the following factors:

- Sustainability mandates and a corresponding consumer demand for green operations, e.g., reducing carbon footprints and lessening the use of resources.

- Thanks to rapid progress in battery technology, charging time, and durability, electric forklifts are now at the same level as (and in some cases even better) internal combustion machines in terms of performance.

- Healthy, safe working environments with better air quality inside the facility and silent operations.

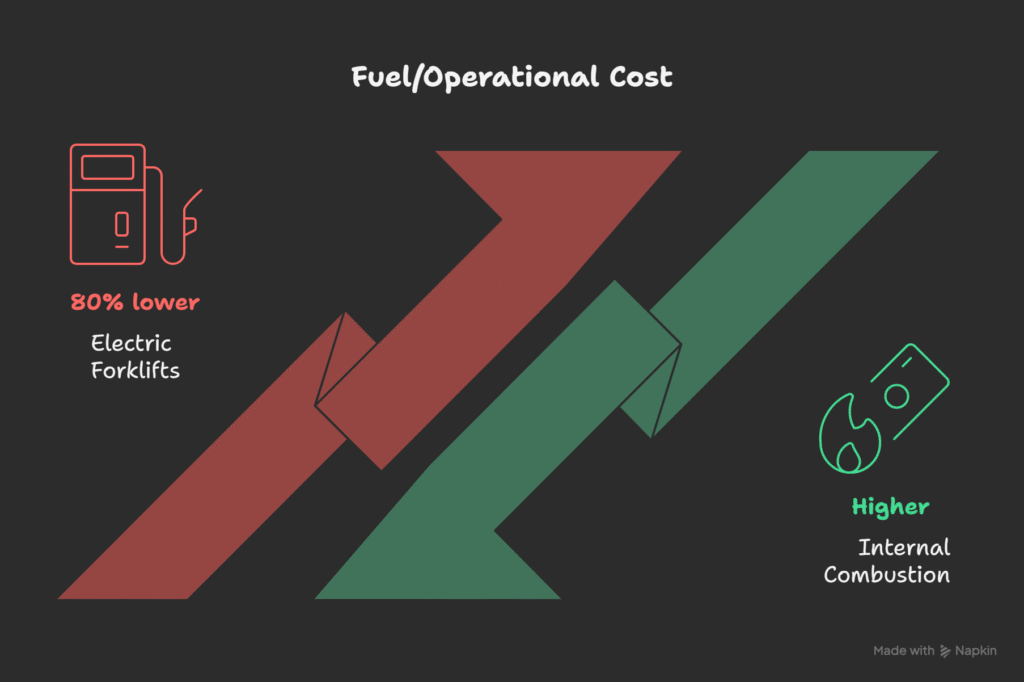

Low Operating Costs and Predictable Expenses

An all-electric forklift fleet is an influential factor in lowering a warehouse’s operating costs across the board. Examples cited by warehouse managers most frequently are:

- What is more, almost 80% of fuel savings can be realized if one compares emissions from internal combustion vehicle fleets with those from electric ones, presuming that no sudden hikes in electricity rates take place.

- It is estimated that half of the maintenance expenses products related to internal combustion forklifts can be cut by electrification of such equipment. The reasons are as follows: less number of moving parts and there is no oil, fuel filters, and exhaust systems—maintenance intervals can be twice as long.

- When energy, maintenance, and uptime are all taken into consideration, electric forklift fleet will have lower ownership costs over the lifecycle of the equipment making them a more financially attractive option.

- Maintenance Advantages: Less Downtime, Fewer Headaches

Order fulfillment centers that operate with a high degree of uptime are the ones that make the most of electric forklift fleets, and such fleets are the ones that can deliver:

- Most of the time when a forklift is not available due to it being on a repair stand, the company is losing money. By removing expensive engine overhauls and fluid changes from the picture, most of the downtime per forklift is brought to a halt.

- Battery maintenance is limited to a few simple tasks such as periodically charging the battery in which its lifetime can be extended by intelligent charging.

- Preventive maintenance tasks become simpler and less frequent due to fewer parts being involved.

Environmental and Health Impact: Cleaner, Safer Operations

Electric forklifts make a large contribution to the health of warehouse environments, especially those that are indoors:

- There is no emission of CO, NOx, or particulate matter—warehouse air quality is enhanced, and employees are less exposed to exhaust fumes.

- It becomes easier to aid the environment through such initiatives while at the same time becoming more compliant with green building and ESG standards.

- Quite likely, at least some of these electric fleet users are powered by partially renewable energy which results in an even smaller carbon footprint.

Performance and Productivity: Modern Batteries, Smart Features

Improvements in lithium-ion batteries, battery management systems, and the flexibility of the charging stations have allowed warehouses to operate for longer hours and increase their productivity:

- Quick charging together with opportunity charging results in no battery change in the middle of the shift and thus, supports three-shift operations.

- Material handling becomes more reliable and throughput is increased with the provision of consistent torque and power output, especially when compared to fuel-powered forklifts that lose power as tanks run down.

- Smaller sizes, the ability to turn tighter, and a more accurate control mechanism enable maneuverability in dense warehouse layouts.

Safety Innovations: Smarter, Safer Electric Forklifts

Today’s electric forklifts are fitted with advanced safety features which, therefore, the adoption of these units has been further supported in warehouses that are risk-conscious:

- Overload protection valves and sensor networks collaborate closely to locate dangerous lifts and also, thus, prevent accidents from happening.

- Automatic emergency braking, operator presence sensors, and collision warning systems help reduce injuries and accidents to the equipment caused, that is, in addition, the emitted sound is decreased, and operator comfort is increased.

- In addition, battery management systems help with the prevention of battery overcharging or overheating, thus, they provide an additional safety layer.

Table: Electric vs Internal Combustion Forklift Comparison

| Feature/Metric | Electric Forklifts | Internal Combustion Forklifts |

| Fuel/Operational Cost | Up to 80% lower | Volatile, higher long-term |

| Maintenance Frequency | Half as often | More frequent, more components |

| Emissions | Zero | CO, NOx, particulates |

| Noise Level | Very low | High |

| Workplace Health | Improved air quality | Potential hazards |

| Maneuverability | Better in tight spaces | Less adaptable |

| Upfront Cost | Higher | Lower |

| Uptime/Charging | Increased uptime | Refueling downtime |

| Sustainability | Supports ESG goals | Less sustainable |

FAQs About All-Electric Forklift Fleets

Are electric forklifts more cost-effective than gas or diesel?

In general, electric forklifts are more cost-effective in terms of ownership and operation compared to gas or diesel ones in the long run as they bring savings in fuel and maintenance.

How do electric forklift batteries compare (lithium-ion vs lead-acid)?

Lithium-ion battery has a longer running time, is charged quicker, and is more durable than a traditional lead-acid one, thus it supports three-shift operations without the need for frequent battery changes.

What are the main maintenance differences for electric forklift fleet?

Electric forklifts are less demanding from a maintenance perspective and the maintenance required is simpler, e.g. without engine oil, fuel filters, or regular exhaust system checks.

How do electric forklifts support sustainability?

Firstly, they are zero-emission, and secondly, they enable companies to achieve environmental targets for both indoor and outdoor material handling by lowering their carbon footprints.

Are electric forklifts safe for warehouse operations?

Yes! Among other things, modern models have safety features such as overload sensors, automated braking, and energy management systems that make everyday operations safer.

What is the impact of electric forklifts on warehouse productivity?

With stable power provided by electric forklifts, the number of breakdowns will be reduced and with the addition of smart features throughput will be improved, especially when lithium-ion battery upgrades are involved.phl

Is the initial investment higher for electric forklifts, and is it worth it?

The initial costs are typically a little bit higher, however, the money that is saved over time – along with the benefits of sustainability and safety – makes them a cost-effective option for most warehouses.

Why Electric forklift fleet Are Rational?

- The rapid pratiation is majorly driven by the basic factors of energy efficiency, lower costs, and better sustainability.

- Leading logistics firms consider healthier and safer workplaces as their non-negotiable conditions.

- The use of smart technology and lithium-ion batteries sets new standards for reliability and performance.

Conclusion: The Electric Forklift Fleet Future

The switch to pure electric forklift fleets is definitely not a short-lived trend. It is a strategic move mainly influenced by the reduction of total cost of ownership, significant environmental benefits, better maintenance and uptime, and state-of-the-art safety technologies. In the case of warehouses, that want to secure their logistics for the future, increase productivity, and at the same time, be environmentally responsible, electric forklift fleet represent the new norm.