A Detailed Comparison of Reach Trucks vs. Counterbalance Forklifts

Choosing the right Reach Trucks vs. Counterbalance Forklifts for their American distribution center or dispersion center is one of the most basic things a coordination’s director can do. This choice will impact everything from how much room you have for capacity and how easily your trade runs to security benchmarks and costs over the long term.

The right approach to handle materials may speed up your work, whereas the inaccurate method might halt your firm in its tracks. The Counterbalance forklift and the reach truck are both vital apparatuses for the company, but they are aiming for different sorts of work and situations.

You require to see at more than fair the “lift and move” work when you compare Reach Trucks with Balance Forklifts. You ought to consider almost how they keep loads steady, how much room they require to work securely, and what sorts of territory they can tackle.

This nitty gritty comparison appears you the key contrasts, which will offer assistance you select the best hardware for your facility’s necessities. This way, you can be beyond any doubt to get the most profitable, secure, and cost-effective arrangement for a long time to come.

The Counterbalance Forklift: Learning the Basics

The balance forklift is the most common and well-known piece of hardware in the fabric taking care of industry. It is the fleet’s rough, adaptable ingenious, built to finish a part of distinctive things in a parcel of diverse areas.

The title stems from the fundamental idea behind the plan: the weight of the truck’s chassis, strikingly the huge mass at the raise (the balance), equalizations the stack being raised at the front. This plan makes a difference the balance forklift get near to a weight, lift it, and move it without having bolster legs that go underneath the load.

In the proceeding contention between Reach Trucks vs. Counterbalance Forklifts, the Counterbalance unit stands out since it is so basic and capable. They are the best alternative for heavy-duty lifting and are habitually the as it were choice when work has to be done exterior of a smooth, level surface in an indoor distribution center.

They are versatile resources since they are well-built and come with a few tire choices. They can stack a truck trailer at the dock inlet or stack beds inside a building with broader aisles.

- Different sorts of control sources: Balance units may utilize a wide run of fills. There are a few Electric (Battery-Powered) sorts that work well interior and in places where emanations are a concern. There are too Inside Combustion (IC) models that work on LPG, diesel, or gasoline, which are vital for long-term open air utilization and greatest supported power.

- Better Stack Capacity: These trucks can carry much greater loads than reach trucks since the counterweight stabilizes them. Standard variations can promptly raise loads of 3,000 to 12,000 pounds. Specialized models can handle loads of more than 50,000 pounds for exceptionally huge mechanical uses.

- All-Terrain Versatility: The balance forklift remains utilitarian and steady on a wide extend of insides and open air surfaces, depending on the kind of tires utilized. For illustration, pad tires work well on smooth interior floors, whereas pneumatic (air-filled) tires work well on harsh, uneven yards or rock surfaces.

Getting to know the Pro: The Reach Truck

The reach truck is the best choice when the fundamental points are to utilize space effectively and maximize vertical capacity. These gadgets were outlined to work in minor passageways that Counterbalance forklifts can’t go through.

In today’s high-density stockrooms, where genuine bequest costs require the utilization of each conceivable vertical foot, the reach truck is an imperative portion of the fabric taking care of system.

The plan of a reach truck understands the issue of space. Instep of as it were having a huge back counterweight, the reach truck has stabilizing legs (outriggers) that adhere out in front of the truck and wrap around the front wheels. This makes a difference hold the stack as the truck gets closer to the racking.

The most vital thing that makes the reach truck diverse is that its pole or carriage (too called a pantograph framework) can move its forks forward by itself. This lets the truck “reach” into the racking to put a stack on or take one off without the entire body of the vehicle going into the rack structure. When you see at space, the reach truck has the most thickness compared to the balance forklift.

- Unmatched Lift Statures: Reach trucks are specialists at getting things up tall. Numerous routine forms can lift loads more than 30 feet, whereas certain high-bay units can carry loads up to 45 feet or more. This lets you utilize exceptionally tall racking frameworks and have the most capacity space possible.

- Tight Passageway Proficiency: Reach trucks can work in passageways that are fair 8 to 10 feet wide (and some of the time indeed less in amazingly tight passageway setups). This implies they require a parcel less zone to move almost than a ordinary Counterbalance forklift, which needs 12 to 14 feet. This might cruel that there are 20 to 30 percent more places to store beds in the same building footprint.

- Electric Control and Indoor Aptitudes: Nearly all reach trucks run as it were on power. This implies they do not transmit any poisons, are noiseless, and are incredible for indoor food-grade, cold capacity, and clean fabricating settings where keeping the discuss clean and clamor levels moo is exceptionally imperative for the consolation of specialists and the quality of the products.

Important Contrasts in Operations: Stature, Width of Passageways, and Capacity

When choosing between Reach Trucks vs. Counterbalance Forklifts, you have to make a fundamental choice: do you need the capacity to lift expansive things and work exterior, or do you need the capacity to store things vertically and move through brief walkways? Knowing the fundamental contrasts in plan and working will offer assistance you make this decision.

Physics and the Soundness Mechanism

The way each machine remains steady when it has to carry a stack is the most critical thing that influences what it can and can’t do.

The teeter-totter concept is what makes Counterbalance forklifts work.

- The stack pushes down on the front of the support (the front pivot), whereas the overwhelming weight (as a rule cast press or lead) built into the back of the machine pushes back.

- The stack is exterior the wheelbase whereas the vehicle is moving, in this manner the truck’s estimate and weight direct how much it can carry.

- The chassis and lifting instrument more often than not taken a toll less to keep up in the long run since they have a less difficult, more grounded construction.

Reach Trucks utilize a combination of stabilization systems.

- The stabilizing legs that expand forward float underneath the load’s racking position, spreading the weight over a bigger, more steady area.

- When the pole pulls back, the stack is drawn back toward the center of gravity of the machine and is incompletely kept interior the stabilizing structure. This lets the machine lift higher with a littler add up to physical impression than a balance unit.

- The extending pole or pantograph framework needs complicated pressure driven and electrical controls, which implies that specialists regularly require extra preparing and maintenance.

Being able to move almost in tight spaces:

The format of a stockroom is based on how distant each truck can turn. This is where the fundamental contrast in competition between Reach Trucks vs Balance Forklifts is most apparent.

- The Counterbalance’s Turning Circle: These trucks as a rule direct utilizing their back wheels, which lets them make uncommonly tight turns for their measure. But since of the tall Counterbalance , the machine has a huge body, which infers that paths require to be 12 to 14 feet wide for secure and wonderful use.

- The Reach Truck’s Tight Efficiency: The reach truck highlights a little chassis and a particular directing component so that the administrator may habitually stand sideways for more prominent locate at tall levels. The truck may work well in walkways that are 8 to 10 feet wide since it can draw the stack back into the body. This incredibly increments the sum of capacity space and vertical space it can hold.

- Twofold Profound Racking Advantage: A few forms of reach trucks come with a double-deep reach connection that lets the administrator get to a bed that is stowed instantly behind another one in the racking framework. This strategy pairs the sum of capacity space along an walkway confront, which is something a normal balance forklift can’t achieve.

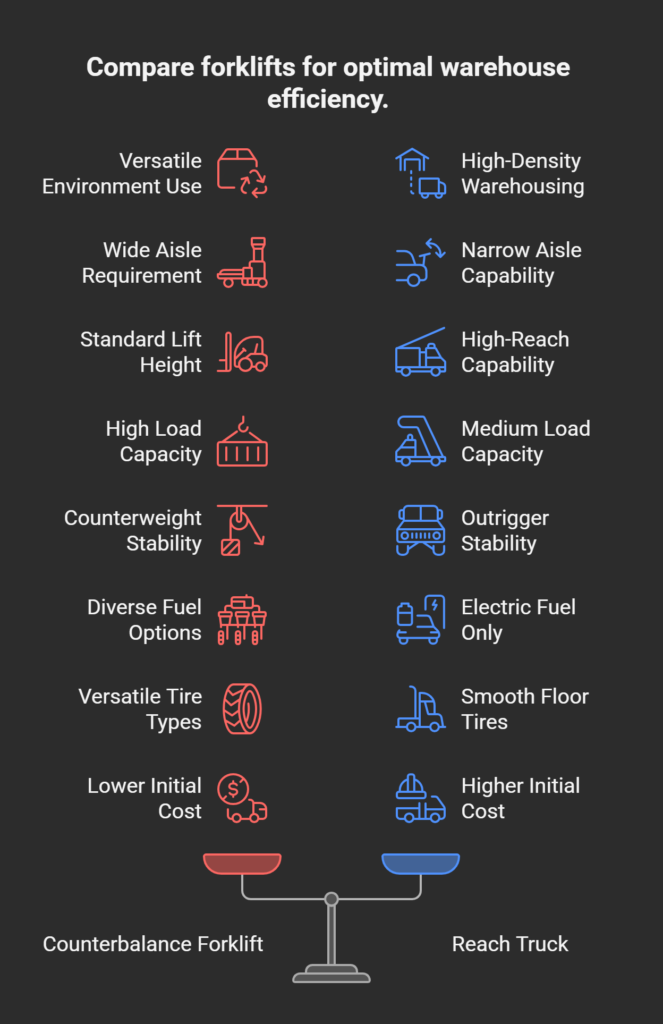

Direct Comparison: Reach Trucks vs. Counterbalance Forklifts

| Feature | Counterbalance Forklift | Reach Truck |

| Primary Use Environment | Indoor, Outdoor, Loading Docks, Yard Work | High-Density Indoor Warehousing, Cold Storage |

| Aisle Width Requirement | Wide (12 ft. to 14 ft. minimum) | Narrow (8 ft. to 10 ft. minimum) |

| Typical Lift Height | Standard: 15 ft. to 20 ft. (Maximum around 25 ft.) | High-Reach: 30 ft. to 45 ft. or more |

| Load Capacity | High (Up to 50,000 lbs. or more for heavy-duty) | Medium (Typically up to 4,500 lbs. / 2.5 tonnes) |

| Stability Method | Heavy counterweight mass at the rear of the truck. | Stabilizing outriggers/legs and internal retraction of the mast/load. |

| Fuel Options | Electric (Battery), LPG, Diesel, Gasoline (IC) | Almost exclusively Electric (Battery) |

| Tire Type | Cushion (Indoor), Pneumatic (Indoor/Outdoor/Uneven) | Cushion or Polyurethane (Smooth Indoor Floors) |

| Cost Consideration | Lower initial purchase price; variable running costs based on fuel type. | Higher initial purchase price; low running costs (electric). |

Total Fetched of Proprietorship and Application Scenarios

The final thing to think approximately when choosing between Reach Trucks vs. Counterbalance Forklifts is how well the gear fits with your company’s special fabric stream and budgetary circumstance. The “best” vehicle is the one that gives you the most esteem for your cash by making the most of your work environment.

Importance of Reach Trucks vs. Counterbalance Forklifts

When to Utilize a Counterbalance Forklift?

If your company has to be adaptable and work well in a assortment of settings, the Counterbalance unit is the best solution.

- Loading and Emptying Trailers: The Counterbalance forklift is the best choice for fast, proficient work at the stacking dock since it can drive straight up to a stack and has the choice of pneumatic tires. This is especially genuine whereas working outside on cook’s garments or ramps.

- Handling Diverse Loads: The Counterbalance’s solid front conclusion and soundness are basic if your trade bargains with a combination of standard palletized things, strangely molded boxes, non-palletized cargo, or needs particular connections like clamps, rotators, or boom poles.

- Long-Distance Transport: When you require to carry things quickly over long separations, such from a far-off accepting yard to the front entryway of the distribution center, the Counterbalance, especially an IC one, can travel speedier and work longer than a reach truck that runs on batteries.

When to Utilize a Reach Truck?

The reach truck is an venture in thickness and vertical space that is as it were accessible in certain circumstances. It gives you a return on speculation not as it were through sheer control, but moreover through space efficiency.

- Maximizing Vertical Capacity Thickness: If your building has a tall ceiling and your primary point is to get as numerous bed positions per square foot as conceivable, you require a reach truck to get to the beat of high-bay racking systems.

- Environmental Affectability: The reach truck must be electric and free of emanations in places where nourishment, drugs, or other delicate commodities are dealt with, or where workers’ wellbeing requires clean, calm operations. This keeps the discuss quality inside the facility.

- Inside Operations: The reach truck is aiming for particular interior errands on smooth surfaces. The reach truck has a parcel of benefits when it comes to moving around inside since it doesn’t have to go outside or drive over harsh ground as well often.

Total Cost of Ownership (TCO)

Counterbalance forklifts are frequently cheaper to buy at first, particularly the IC (LPG/Diesel) models. The TCO of a reach truck, on the other hand, is usually competitive or even lower over time, particularly in locations where it is utilized a lot. The reach truck just needs electricity to work, which makes it cheaper to fuel.

It also has fewer moving parts that may go down (no engine, transmission, or intricate internal combustion systems), and it needs less maintenance for things like oil changes, spark plugs, and filters.

But if anything goes wrong with a reach truck’s advanced electronics and hydraulic systems, which are required to extend the mast, it might cost more to repair. When TCO compares Reach Trucks to Counterbalance Forklifts, they need to think on how much more storage space the reach truck has.

FAQs: Reach Trucks vs. Counterbalance Forklifts

Which kind of forklift is the safest for lifting really big loads?

The Counterbalance Forklift. Because it uses the whole weight of the machine plus a large back counterweight to balance the load, it is naturally more sturdy and strong for lifting the biggest loads. Because of how the extending mast works, reach trucks can only carry lower weights (around 4,500 lbs. maximum) compared to the Counterbalance’s full capabilities.

Can I use a Reach Truck to load and unload regular road trailers?

It is conceivable, but not advised as a main function. Reach trucks are not equipped to handle rough outside terrain, driving over uneven trailer gaps, or functioning on ramps. They are only meant to be used on smooth, level interior surfaces. The Counterbalance forklift is built to operate on docks.

What is the main benefit of a Reach Truck versus a Counterbalance?

It can work well in small aisles (usually 8 to 10 feet wide) and stack pallets to very high heights (up to 45 feet). This lets warehouses to improve their storage density and capacity without having to build more space.

Are there LPG or diesel variants of Reach Trucks?

No. Reach trucks are designed to work in confined aisles inside and are virtually always driven by electricity (battery). This makes sure that there are no pollutants and very little noise, which are both important for working inside with a lot of people and keeping workers safe and comfortable.

How can a Reach Truck stay stable without a big counterweight at the back?

It has two ways to keep it stable: first, the outrigger legs (or base legs) extend forward to hold some of the weight of the load; and second, the mast mechanism pulls the load back toward the center of the machine and over the wheels, using the heavy battery pack as part of the overall stabilizing mass.

What kind of forklift needs more training for the operator?

The Reach Truck. All forklifts need approved training, but driving a reach truck needs more skill since the operator stands sideways, uses a joystick or other complicated controls, and has to be able to deposit and retrieve loads accurately at very high heights.

What kind of industrial vehicle is a Reach vehicle in the material handling business?

Electric Motor Narrow Aisle Trucks are the second class of trucks that reach trucks belong to. Depending on what powers them, counterbalance forklifts are in Class I (Electric), Class IV (Internal Combustion, Cushion Tires), or Class V (Internal Combustion, Pneumatic Tires).

Conclusion: Making the Smart Investment

When deciding between Reach Trucks vs. Counterbalance Forklifts, you need think about your company’s area, load, and surroundings. The Counterbalance is the best choice for your facility if it is large and contains outdoor yards, heavy goods, and varied kinds of terrain. You need a professional Reach Truck if your firm is in a modern, high-bay facility where generating money depends on making the most of vertical storage and navigating around narrow aisles.

Smart logistics planning usually includes a diversified fleet. Many places use powerful counterbalance forklifts at the loading dock to rapidly turn around cars and drive them outdoors. They also deploy electric reach trucks in the main warehouse area for high-density storage since they are accurate and can reach high areas.

You can be sure that your material handling solution is safe, effective, and in line with modern American logistics if you carefully compare your operational needs to the distinctive characteristics of Reach Trucks vs. Counterbalance Forklifts.