How Loud is an Electric Forklift? A Silent Revolution in Warehouse Safety

Today, the operation of warehouses has shifted dramatically from shelves higher than the smoke and noise of internal combustion engines to a cleaner, more efficient, and much quieter future. For those in charge of running a warehouse used to the sound of the diesel or propane engines running, the change to electric material handling equipment brings a total change in the world of sound. The question we hear most often at American Forklifts is: How loud is an electric forklift vs. a traditional forklift?

The answer goes far beyond comfort. It forms a key part of safety, communication, and compliance with OSHA in a working environment.

The quietness of an electric forklift is frequently compared to stealth mode, aiding people talking to each other at normal volume. It still has enough power to perform heavy industrial work. IC forklifts depend on a fuel explosion to generate power, so they create noise, vibration, and exhaust, whereas electric forklifts have battery-powered electric motors that hardly make any noise at all.

Reduction in noise levels is not a mere indulgence; it is a well thought through business move which can not only reduce insurance risks and lowering operator fatigue but also help increase the long-term health of your workforce radically.

The Decibel Difference: Electric vs. Internal Combustion

We use decibels (dB) as the unit to measure the loudness of a sound. To get a full picture of just how quiet an electric forklift is, we need to see where it stands in relation to the sound level inside a factory and also to the sound level of a few other competing technologies.

During normal working, an internal combustion forklift (diesel or LPG) would be generating a noise level around 85 to 95 decibels (dBA), and the level can go even higher during heavy lifting or fast acceleration. An electric forklift, on the other hand, is usually producing a noise level of about 60 to 70 dBA, similar to the sound of two people talking in an office or that of an air conditioner.

The difference of 15-25 decibels comes with a logarithmic scale, which means, the perception of the loudness of the electric forklift accounts for more than just the hearing of a little difference; it is very far less to the human ear.

- Internal Combustion (IC) Forklifts: The use of such machinery results in lot of noise pollution since combustible fuel engines are there and exhaust is expelled and fan noise also gets added. If there is too much exposure, one may have to protect their ears by wearing ear muffs or plugs to avoid such levels of noise, according to health and safety norms.

- Electric Forklifts: The main noises that can be heard in the operation of electric forklifts are the sound of tires rolling on the floor and the high-pitch sound of the hydraulic pump when lifting the load. Because of the absence of engine idle noise, the sound of a stationary forklift is almost non-existent.

- Ambient Warehouse Noise: When old IC trucks are replaced with new ones, the overall noise level of a facility goes down drastically. The previously chaotic echo chamber becomes a controlled working space where verbal commands can be heard easily.

- Why “Quiet” Equals “Safe”: The Communication Factor People incorrectly assume that a noisy piece of equipment is a safe one because the people on foot can hear it from far away. However, when there are many IC motors running in a warehouse, the sound created by those engines becomes a “wall of noise” and this, in turn, leads to the workers experiencing sensory overload and other important alert signals getting drowned. With an electric forklift, the noise around the workers is decreased, and as a result, the workers get to dwell on specific, unique warning signals rather than on a continuous background noise that is loud and uninterrupted.

When the background noise is reduced, safety can be seen to be improving in several ways:

- Clearer Verbal Communication: Workers no longer need to shout to communicate their needs to one another. This helps in sharing of information related to the right placing of goods, the flow of the traffic inside the shop floor and how to stay safe from hazards, with minimal chances for error.

- Audibility of Alarms: Safety mechanisms like backup warning sounds, blue spot safety lights, and horns become more prominent and distinct when operating a quieter forklift. They don’t have to compete with the loud engine noise anymore, enabling them to be even more effective in alerting pedestrians.

- Reduced Operator Fatigue: Constant exposure to high noise levels causes physical and mental stress, known as “noise fatigue.” It’s no wonder then that operators in quieter electric cabs report more energy at the end of their shift, and higher levels of alertness during work, implying that fewer accidents occur because of tiredness.

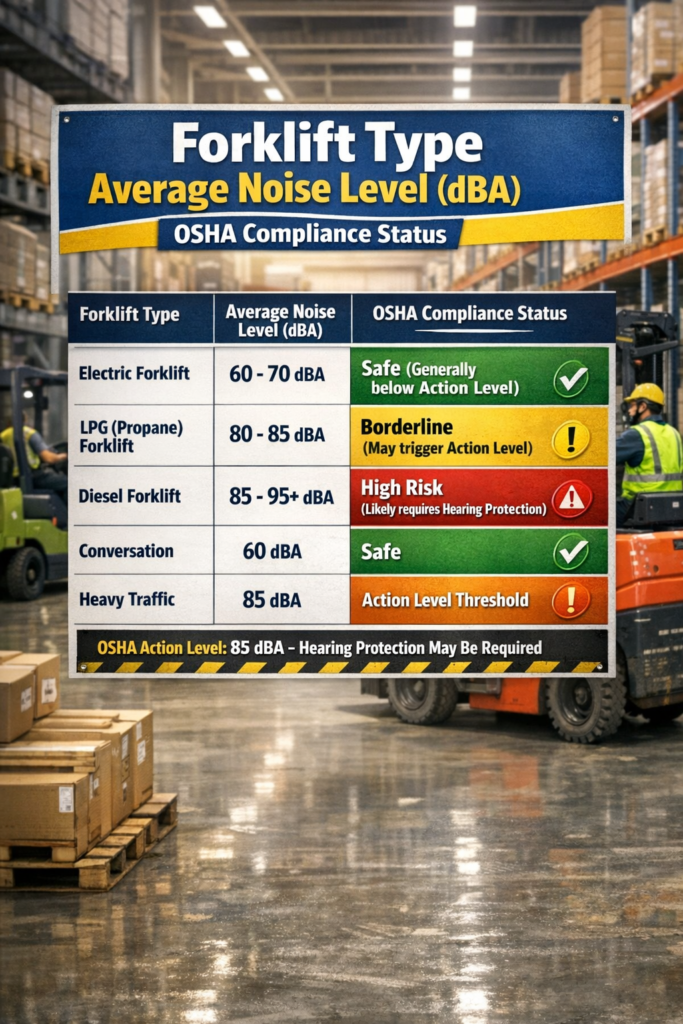

OSHA Regulations and Noise Exposure Compliance

The Occupational Safety and Health Administration (OSHA) has a strict limit on the noise levels to which workers are exposed so as to prevent hearing problems. 90 dBA is the Permissible Exposure Limit (PEL) for an 8-hour work shift. Further to this, 85 dBA is the “Action Level”, which signifies the threshold level at which the employer must start a hearing conservation program.

- Complying with rules becomes a problem for safety management if a company through its fleet of internal combustion forklifts operates right at the edge of these limits.

- Hearing Conservation Programs -By converting the fleet to electric, companies can often bring average noise levels well under 85 dBA, the OSHA Action Level, thus eliminating the extensive and costly hearing testing, audiograms, and the documentation of training programs demanded by the law.

- Foratery devices cultures PPE in the music of the game. Workers in an environment where high noise levels do not exist will be able to perform their tasks without using wearing bulky ear protection is less of a big deal and workers’ safety, comfort, and situational awareness will be greatly enhanced as they are less isolated from the surrounding environment by earplugs or muffs.

- Long-term liability reduction. Hearing loss claims are a profound industrial sector’s liability. One step ahead in noise reduction policy is to decrease the source of the noise-the forklift engine itself. This way, companies are less vulnerable to workers’ compensation claims arising from hearing damage in the future.

Forklift Type Average Noise Level (dBA) OSHA Compliance Status

| Forklift Type | Average Noise Level (dBA) | OSHA Compliance Status |

| Electric Forklift | 60 – 70 dBA | Safe (Generally below Action Level) |

| LPG (Propane) Forklift | 80 – 85 dBA | Borderline (May trigger Action Level) |

| Diesel Forklift | 85 – 95+ dBA | High Risk (Likely requires Hearing Protection) |

| Conversation | 60 dBA | Safe |

| Heavy Traffic | 85 dBA | Action Level Threshold |

Factors That Can Increase Electric Forklift Noise

Inherently, electric forklifts are super quiet, but they are not silent and they shouldn’t be either. Different mechanical and environmental factors can have an impact on the running volume.

Maintenance crews must be able to tell apart normal electric sounds from sounds that point to a problem. Even the quietest unit will turn into a noisy one if it is neglected or the wrong parts fitted.

Unarguably, the quietness that is associated with the term “stealth” can only be preserved if certain factors are carefully watched and controlled:

- Tire Selection and Condition: The noise made when the tire touches the floor is in most cases the loudest sound coming from the movement of an electric forklift. When a hard cushion tire is used on rough concrete, the sound produced will be louder than when a pneumatic tire is used on asphalt. In addition, small stones stuck in the tire or flat spots can cause rhythmic banging sounds thus increasing the level of decibels.

- Hydraulic Pump Whine: During the operation of lifting heavy load, hydraulic pump is by the electric motor driven which results in Pump gets a high-pitched “whine” or a hum sound. This is a normal occurrence but an increase in the volume of the whine can be one of the indicating signs of issues such as low hydraulic fluid, air in the lines, or even a pump that needs to be repaired.

- Safety Alarms and Horns: Unexpectedly, the overly quiet forklifts have caused many businesses to use louder-than-average backupproblems, “white noise” travel alarms so that pedestrians can get an easy visual cue of the presence of the vehicle. These are phenomenon noise sources introduced purposely in order to break through the silence and thus help the safety of people around.

The Role of Maintenance in Keeping Forklifts Quiet

In an electric system, silence is basically the sign of proper functioning while noise usually comes from worn parts. A regular maintenance plan is one of the most effective ways of keeping an electric forklift not only quiet but at a high-performance level.

At American Forklifts, we tell our customers that if you ever hear a loud noisy electric forklift around, it probably means that the machine needs some fixing.

Essentially, the soundproofing record of your maintenance activities should be checked against the following points:

- Lubricating Mast Chains and Carriage: Grinding, screeching, and other metal-on-metal friction sound are the most common ways through which a running machine can produce loud noises. When you thoroughly and regularly grease the chains, side shifters, and the channels of the mast, you can expect fastening and lowering operations to be carried out smoothly and quietly.

- Brake Assembly Checks: The regenerative braking system in most electric forklifts is very quiet. If the pads are worn out or if dust gets accumulated in the drums, then the service brake mechanism may produce squeaks and squeals. Dust in drums and pads can produce this sound. Thus, frequently cleaning brake assemblies and adjusting them prevents a high-pitched sound when stopping.

- Tightening Body Panels and Overhead Guards: Vibration may cause bolt loosening on body panels and overhead guards which in turn causes a rattling. This rattling effect does not only contribute to the noise floor but also leads to structural fatigue. Periodically, the bolts should be tightened back to ensure that the machine is solid both in feel and sound.

American Forklifts: Your Source for Quiet Power

We at American Forklifts realize that the today’s warehouse not only requires equipment that is powerful but also less obtrusive. We carry the very newest of lead-acid and lithium-ion electric forklifts that give you the torque of a diesel without all the noise and hassle of it. We are committed to assisting businesses move effortlessly into the quieter and cleaner world of logistics.

Whether you plan on buying or renting, our range of different models offer you the following benefits:

- Top-Tier Electric Models: We carry well-renowned brands that are recognized for their soundproofing features and ergonomic designs. The motors of these machines are insulated and they operate with helical gears which are smoother and thus quieter than the old technologies.

- Custom Safety Add-Ons: Since our forklifts generate very little noise, we can add our specialized pedestrian-awareness lighting to ensure visual safety and thus reduce the need for the incessant use of horns.

- Expert Maintenance Support: Our service team is very knowledge regarding tuning an electric to keep it running at it speak stealth performance level. From to tire replacement, hydraulic fluid top-offs we make sure your fleet stays as loud as the day you bought it.

FAQs – Electric Forklifts:

Are electric forklifts safer because they are quieter?

Generally, forklifts that are quiet are safer as they lower the fatigue level of operators and make workers’ communication easier. However, due to their extremely quiet operation, the pedestrians may not hear them coming. In order to help the warehouse staff know of their presence, the electric forklifts must hence be equipped with backup alarms, horns, and visual safety lights (like blue spotlights, etc.).

Do electric forklifts have engines?

No, electric forklifts don’t come with internal combustion engines. They are entirely dependent on the large batteries that power electric motors. Most likely, it would not be a surprise if such electric forklifts run very quietly as significantly less parts, such as pistons, spark plugs, and exhaust manifolds, that are responsible for combustion noise are missing in them.

Can I use electric forklifts outdoors?

Yes, electric forklifts nowadays not only function indoors but have outdoor capabilities as well. However, it is always primarily an indoor vehicle, so if the newer model which runs at higher voltages (80V) and has pneumatic tires is going to be taken out on the street, one would have to be prepared for the slight increase of noise that is caused by rough outdoor surfaces in contrast with smooth indoors concrete. Still, it is possible with electric forklifts today.

How much do electric forklifts reduce warehouse noise pollution?

One great advantage of swapping a diesel truck fleet with an electric truck fleet is the drastic reduction of the ambient noise in the parking area by 10-15 decibels or even more. Most of the time, this reduces the noise from the level of the OSHA Action Level of 85 dBA to a point where hearing protection is no longer required, and the working environment is way more comfortable.

What is the average lifespan of an electric forklift battery?

The typical lead-acid battery used in a forklift will last for about 1,500 charging cycles (roughly 5 years if the battery is being charged once daily). Lithium-ion batteries are more durable and can last for 2,000 to 3,000 cycles or more, besides they do not require maintenance and “cool down” time that lead-acid batteries do. Both types of batteries are silent during operation.

Why is my electric forklift making a whining noise?

Typically, the hydraulic pump is the source of whining noise from an electric forklift. The pump is activated when the lift or tilt function is being operated, which is visibly supported by the operator. When some hydraulic fluid leaks occur along with a pump that is not working properly, a filter is clogged; the result is a high-pitched sound that intensifies and becomes unpleasant. The operator should have the motor checked immediately if he hears a very loud noise from the pump.

Are electric forklifts more expensive than gas forklifts?

In most cases buying an electric forklift along with a battery will cost a little bit more than a propane or diesel model. Total cost of ownership will be quite lower eventually in the case of electric trucks due to significantly lower spendings on fuel that is cheaper and also getting less wear and tear from the machine parts replaced less often because the device has fewer moving components.