Implemented Electric forklifts in manufacturing plants, electric forklifts are a viable option for modern industry to go green and save costs with great efficiency. Nevertheless, the use of electric forklifts also brings certain challenges and maintenance needs to the operation. The right method of selection with productivity, worker safety, and logistical flows being at their maximum while hidden costs and downtime at their minimum, is the essence of the below in-depth blog.

Introduction: Electric Forklifts in Manufacturing

The growing use of electric forklifts has been a key trend in daily material handling at US manufacturing plants. The introduction of the electric forklifts has been a win-win for the indoor plants where air quality, operational noise, and maintenance costs have become major deciding factors for the change.

In fact, they are becoming the main choices for facility managers and their logistics teams due to their low emissions, reduced total cost of ownership, and suitability to sensitive goods like food and drugs. However, a step in the right direction is a well-balanced plan that guarantees the all-time productivity of the industries with heavy flow and variable shift schedules when talking about the initial investment, charging infrastructure, and load-specific restrictions.

The Pros of Electric Forklifts in Manufacturing Plants

Electric forklifts have various pros that may raise their claim to being the perfect match in the manufacturing departments, especially those which have the aspects of cleanliness, efficiency, and safety as their most valued.

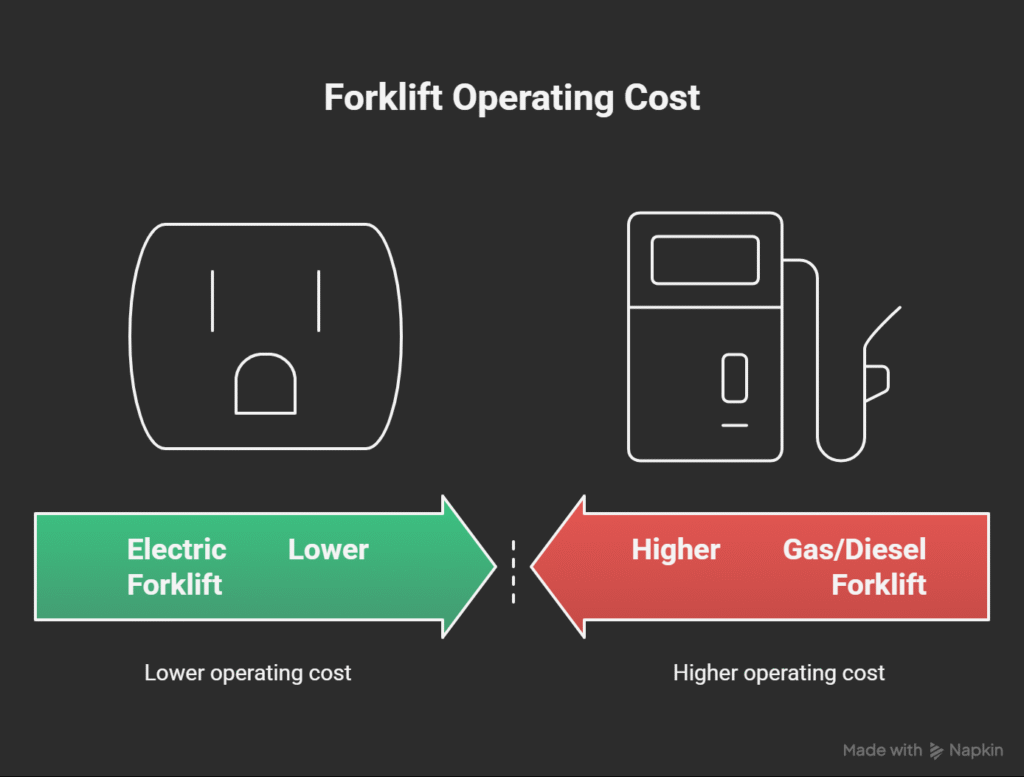

Lower Operating Costs and Energy Efficiency

The presence of electric forklifts in industrial venues is a move in a direction that will help save the factory long-term operational costs and also make the overall energy use more efficient.

- As a rule, one may expect power to be cheaper and much more stable in price compared to fuel types such as diesel, LPG, etc., that enable operators to recharge the machines during off-peak hours and so optimize their shift schedules.

- The conversion of internal combustion engines into battery-powered forces a drastic reduction in the needs for change of fluids and routine checkups hence it leads to fewer machines idle times as well as maintenance will be lower priced throughout their lifecycle.

- To mention only a few of the benefits of modern lithium-ion technology, the main one is getting the longest operational uptime, the fastest charging, and the highest battery lifetimes for most manufacturing needs.

Environmental and Workplace Benefits

Going electric may be just what it takes to have the company comply with regulations and at the same time enjoy the benefits of the change.

- Electric forklifts do not release any emissions while on-site, thus, operators are in a safer environment and the chances of the contamination of products are minimal – which is very important in the food or drug industries.

- Compared to the noisy internal combustion machines, electric models offer much quieter operations thus allowing for better communication as well as less relaxed operators fatigue from a busy worklist.

- Besides exhaust removal, it is also an option for plants to save on heating and cooling costs, and they are able to use their facility allocations in a more flexible way.

Improved Maneuverability and Safety

The maneuverability that today’s electric forklifts give to their users is nothing short of excellent, thus, they are almost a must-have in the tight space of manufacturing plants.

- Most agile turning radii allow you to easily travel through narrow aisle and crowded production lines, which by virtue of compact manufacturing layouts, become time-saving and efficiency-enhancing.

- Due to their lower center of gravity, the stability of electric forklifts is better than those of internal combustion engines, plus, improved rear visibility because the battery is used as the counterweight instead of the gas tank.

- Fully developed electronic surveillance systems guarantee safety while they work, e.g. they limit top speed, apply automatic braking, and give a continuous state of battery charge through the display.

The Cons of Electric Forklifts in Manufacturing Plants

The decision to install an electric forklift should not be taken lightly due to the existence of their shortcomings and difficulties. Nevertheless, electric forklifts continue to command an increasing portion of the market by their soft merits and a good fit with the operation.

Higher Initial Investment

The transition from gas to electric is most commonly hindered by the upfront capital outlay.

- Parts of the price tag variation that comes with electric still forks mostly depends on whether they use lithium-ion batteries or not that is why they are comparably costlier in full with respect to their traditional internal combustion tank releases.

- Charging facility reconversion-wise costs, which include setting up designated charging zones, electrical work costs, and safety upgrades, are among the costs that have to be considered to calculate the ROI for use of electric forklifts in factories.

- While unknown battery replacement may occur after some years of service, and on such times the battery should be replaced, the circumstances can be a significant issue when the battery reaches the end of its service life.

Load and Duty Cycle Limitations

- Electric forklifts in manufacturing are not the best option for every heavy load application in manufacturing, especially rest less 24h working, long-heavy-duty shifts, or outdoor where battery charging or changing is not possible.

- Notwithstanding the fact that electric forklifts are hard-pressed to dance the score of heavy-duty outdoor, rugged operations, and perhaps nothing of heavy lift, they are, nevertheless, fit for most industrial battery energy technologies or quick swap systems.

- Long continuous hours with only one set of batteries are not advised, modern cell systems are prepared to undertake a battery backup, as such, additional stock of power cells or quick-change stations/methods are a viable emergency solution.

Alternatively, machines designed to lift heavy-weight electric-powered are may not perform up to that of diesel or LPG-powered counterparts and, therefore, restrain their application in jacks or heavy manufacturing sectors.

Charging and Downtime Concerns

Deliberate battery management is the key to the avoidance of unexpected downtime situations.

- The charging operations have to be done with particularly increased caution – overcharging or undercharging may shorten the battery life and raise the cost of operations if not carefully supervised.

- Workers who assist in the charging process have to be very careful in following the safety rules so as not to allow arcing or battery leakage in the charging bay.

- It is noteworthy to add that if the battery happens to run out unexpectedly in the middle of a shift, then the production line will come to a sudden halt, therefore, a very good scheduling of work along with an alert system should be there to avoid such a predicament.

Best Practices: Maximizing Value of the Electric Forklifts in Manufacturing

Taking into account the safety, efficiency, and cost-effectiveness in the use of electric forklifts in manufacturing situation, it is best for a facility to have the combination of operational best practices and strategic planning in place.

Pre-Operational Safety and Maintenance Protocols

Regular checks and timely maintenance are the foundation for the provision of safety and the performance of the machine in question.

- The pre-shift inspections done by operators prior to the battery check, the hydraulic system check, and also all the major controls must be tested out to ensure their reliability in operation for every working day.

- The maintenance that is done at the intervals recommended by the manufacturer not only prolongs the lifetime of each forklift but also prevents the occurrence of an expensive, unexpected breakdown.

- Step by step checking of fork types, mast, tires, and safety devices in minimizing the risk of mechanical failure and regulatory citations – the reference guides such as the in-house .org one with checklists for detailed task dividing work are good examples.

Safe Operation and Training

Trained operators and safety-compliant infrastructure constitute the minimum that is required to have material flow without any kind of incidents in the area.

- Operators should be equipped with Personal Protective Equipment (PPE) that matches the plant they are working in i.e. safety shoes, high-visibility clothing, and gloves.

- The facilities can put the markings of traffic routes, use the barriers to separate the lanes for pedestrians and forklifts, and ensure that all the operators are trained in both general and electric forklift-specific protocols.

- Safety emphasis by way of enforced strict speed zone, safe operation such as never carrying passengers; refraining from lifting while moving, and promoting a safety-first culture is bound to lead to less injuries and downtime.

Battery Management and Charging Infrastructure

Good battery use, rotation, and safe charging, among other things, are the keys that open the door to successful shift-based manufacturing operations. Pick and mark locations for the charging bays, which should be locales that are well aerated, away from the main paths, and equipped with fire extinguishers and safety signs that would keep them safe.

- For the use of traditional lead-acid batteries, one should water the battery and use only the chargers approved by the manufacturer. Modern lithium-ion systems help cut the maintenance

- Supervisors are enabled by digital monitoring technologies to replacing batteries before entirely running out, letting them plan battery swaps thus avoiding equipment fails that are unplanned.

Table: Gas/Diesel vs Electric Forklifts for Manufacturing

| Feature | Electric Forklift | Gas/Diesel Forklift |

| Emissions | None | CO2, NOx, particulates |

| Operating Cost | Lower | Higher, volatile fuel price |

| Noise | Low | Higher |

| Maintenance | Less frequent, simpler | More frequent, prone to leaks |

| Maneuverability | Tighter radius | Standard |

| Initial Investment | Higher | Lower |

| Duty Cycle | Limited by battery | Continuous with refueling |

Hence: Powering Productivity Sustainably

Nowadays, electric forklifts are at the core of modern factories having been the perfect ecofriendly solution, offering savings as well as performance improvement if introduced and maintained correctly as per plant-specific parameters.

Along with solid safety, on-time service, and good battery management that guarantees the maximum spectrum of utility of these high-technology machines over a long period, the smart choice of electric forklifts is no longer just about hitting sustainability goals but a sustainable productivity, workers wellbeing, and regulatory peace of mind investment.

Electric Forklifts in Manufacturing – Frequently Asked Questions

How does an electric forklift differ from a gas or diesel forklift?

Electric forklifts are powered by batteries—usually lithium-ion or lead-acid—instead of internal combustion engines and thus are zero emitters, quieter, and simpler to maintain, although they may require more capital investments and a closer look at charging cycles.

Are electric forklifts suitable for heavy-duty manufacturing applications?

Electric forklifts that are updated can take most of the load in the factory but they may lose a lot of their capability if the work is rugged and performed outdoors with high capacity unless the latest high voltage battery or rapid swapping system is used.

What safety protocols should be followed when operating electric forklifts?

Some of the best practices are the pre-operational safety checks, the use of correct PPE, following the manufacturer’s maintenance schedules, only charging in safe places, and following the clear instructions for separation of pedestrians and forklifts.

What are the environmental benefits of using electric forklifts in manufacturing?

Since electric forklifts do not have on-site emissions, indoor air quality is improved and therefore factories that produce in sensitive zones will be able to meet regulatory standards for environmental sustainability.

How long does an electric forklift battery last?

Basically, a modern forklift battery will last for about 5-7 years if it is properly maintained, even though lithium-ion batteries will most likely have longer service intervals than conventional lead-acid ones.

What are best practices for charging and rotating electric forklift batteries?

We recommend that each battery is charged only at its designated location, that the rotation is done in a way that the batteries never get to be deeply discharged, and that maintenance is done according to the type(watering for lead-acid, monitoring cycles for lithium-ion) batteries with the use of digital alerts to avoid that the battery runs out without the operator noticing during critical manufacturing shifts.

What common mistakes can reduce the lifespan of electric forklifts in manufacturing?

By not doing the scheduled inspections, charging the battery improperly, not keeping the battery in good condition, and not training the operator while pretending to be the victim of premature parts failure and increased operating costs are some of the major reasons for shortened battery life.