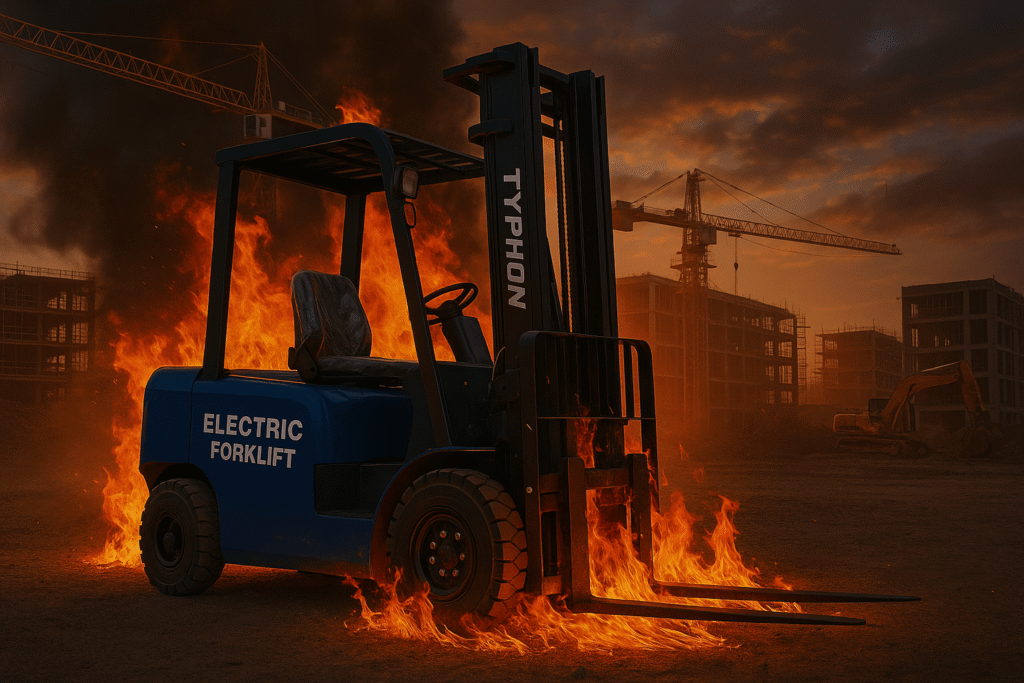

Fire Safety 101: Everything You Need to Know About Electric Forklift Fire Extinguishers

Electric forklift fire safety is a crucial matter. We know fire extinguishers are a standard precaution, but are they enough? What kind of electrical forklift fire extinguisher should you go with?

The most common and the best one is a Class C (ABC Dry Chemical or CO2) fire extinguisher made specially for electrical fires. Although no explicit requirement from OSHA exists, workplace safety calls for adequate fire protection measures. Here we will walk you through a step-by-step guide of what you should know about electric forklift fire extinguishers.

Regardless of whether you are a safety manager or a forklift operator, mastering these basics is important for keeping a safe workplace environment.

Key Takeaways:

- Class C is the fire extinguisher exclusive type (ABC Dry Chemical or CO2) for the electric forklift support.

- Safety compliance with fire extinguishers is a must in workplaces, despite OSHA regulations that don’t mention forklifts’ fire safety requirements. On the other hand, OSHA has not set specific regulations for fire extinguishers in forklifts. However, it is still indispensable to make fire prevention and fire protection measures a part of the general safety regulations which are applicable to workplaces.

- Maintenance on a regular basis, timely check-ups, and correct installation in easily reachable places are the things that keep the fire extinguisher in top condition

- Proper training for forklift operators is the only way to make the fire safety technology understandable to them so that they can respond correctly to emergencies

- Lithium-ion battery-powered forklifts are the ones that the management of the company should pay special attention to, caused by the fact that this type of trucks can create unusual fire threats if proper preventive measures are not taken

Types of Fire Extinguishers for Electric Forklifts

Class C Fire Extinguishers

For electric forklifts, the right choice of a fire extinguisher is a must for safety. It is a fact that the Class C fire extinguishers are very effective against electrical fires, and, therefore, are the only choice for electric forklift operations.

Such extinguishers are usually filled with substances like dry chemical or dry powder that are not conductive. The non-conductive feature is essential, because a conductive substance used on an electrical fire may endanger the operator of the truck.

In case of electrical outbreaks, carbon dioxide is number one. It not only puts the fire out but also oxygen is displaced, and as a result, no trace is left behind. Moreover, it is a fact that the sensitive electrical parts are not damaged this way.

Multi-Purpose ABC Extinguishers

For all-round protection, a majority of plants prefer multi-purpose ABC extinguishers. These versatile units can manage various types of fires, such as:

- Class A fires (ordinary combustibles like wood and paper)

- Class B fires (flammable liquids)

- Class C fires (electrical equipment)

Normally in ABC extinguishers, a dry chemical agent consists of a mix of monoammonium phosphate and ammonium sulfate. This fusion creates a very efficient fire-fighting substance that:

- Form a barrier between oxygen and the fuel source

- Cut the chain reaction of the fire

- Provide the fast knock down of the flame

Should you wish to purchase a fire extinguisher for your electric forklift, the operating environment and potential fire hazards have to be considered. While Class C extinguishers are sufficient for electrical fires, an ABC unit can be used universally to fight different types of fires.

💡 Key Takeaway: Select either a dedicated Class C model extinguisher for your electric forklift electrical fires or a multipurpose model ABC fire extinguisher which contains dry chemical agents for total protection from fire, so that you are well prepared to fight different fire hazards that might arise in the various scenarios.

Regulatory Requirements and Standards

A variety of regulatory bodies and standards that provide a safe working environment and ensure that regulations are being adhered to govern the landscape of electric forklift safety.

OSHA Guidelines for Electric Forklifts

The approval of safety regulations by the Federal OSHA for electric forklifts is one source of safety guidance. The regulations stipulate that the highest level of safety for the electric forklift is the requirement of the employer and hence have to be in compliance with the determinants that the workplace is prone to based on the general hazard assessment.

It is important to bear in mind that in addition to federal OSHA standards, there will be other requirements enforced by jurisdictional authorities. These are the more stringent safety regulations for electric forklifts that local and state regulations may set in place.

The safety triple bottom line of the work protection agency comprises:

- Achieve the exact hazard assessment of the working place

- Carry out all the necessary fire preventive measures for the safety.

- The company must keep a good record of its safety protocols.

- Training and certification must be done to the operator.

- Adhere to the safety regulations of the manufacturer for the safety machine.

When the fire protection equipment is from the manufacturer, it is still the company’s responsibility to follow the standards set by OSHA for maintenance of this equipment. OSHA’s compliance with safety standards is the reason why any changes of these protective features must have the manufacturer agree.

Not only would local fire marshals but insurance providers bring in more demands than just the OSHA. These demands typically may vary according to the kind of industry, the size of the premises, and the various operational risks.

💡 Key Takeaway: Even though federal OSHA does not specify that electric forklifts are to have fire extinguishers, local laws in the comprehensive safety regulations still require the provision of the right fire prevention method according to the specific workplace hazards and likewise according to local jurisdictional requirements.

Operator Training Requirements

Fire Safety Training Protocols

A full-scale fire safety course is like the one the fire service uses that must be attended by each forklift driver who has to be certified. The function of this training is to ensure that the person will understand how to behave in the case of a fire and will also establish the safety of the place.

An effective training program should not only include theoretical knowledge but should also consist of hands-on practice. Employees achieve a good command on how to prevent fire in the workplace, know different types of fire, and exercise right skills to use an extinguisher at any moment.

The contents of the training include:

- Recognition of fire warning signs

- Understanding electrical fire characteristics

- Proper evacuation procedures

- Emergency response protocols

- Fire extinguisher operation techniques

- Regular safety equipment inspections

Adequate training emphasizes the necessity of fast decision-making during an emergency. Employees have the required information to be able to quickly size a situation and decide on a necessary course of action, whether that is to try to put out a small fire or to start an evacuation.

Regular refresher training is essential for keeping safety at the workplace a priority. These training sessions allow employees to always be current with the newest security protocols and to enhance their emergency response skills. The training records must be saved and checked frequently to get confirmation that they are in line with the set standards.

The main areas of practical training consist of:

- Fire extinguisher deployment practice

- Emergency shutdown procedures

- Communication protocols during fire incidents

- Equipment inspection routines

- Evacuation route familiarization

Before a worker is allowed to drive a forklift, it is the employer’s duty to ensure that the employee is equipped with fire safety procedures who has a good competence. A typical manner of the verification is through both the written assessments and practical demonstrations.

💡 Key Takeaway: Extensive fire safety training is indispensable for forklift operators. It should pair theoretical knowledge with practical skills in order to ensure a prompt and efficient emergency response and workplace safety compliance.

Conclusion

Fire safety for electric forklifts is crucial for workplace safety and resilience, not simply compliance. From selecting the right Class C fire extinguisher to maintaining regular maintenance schedules and operator training programs, following this guidance will make your workplace safer.

Remember, fire safety requires knowledge and readiness. Maintain fire extinguishers by keeping them accessible, properly installed, and inspected regularly. Make sure your forklift operators are well-trained in fire extinguisher usage and workplace safety.

Compare your fire safety procedures to these criteria today. Conduct a safety audit, update your training, and check your fire extinguishers’ compliance. Your fire safety pledge will protect your employees and demonstrate your commitment to a safe and compliant workplace.

FAQs

How often should electric forklift operators receive fire safety training refresher courses?

An electric forklift driver should undergo fire safety training at least once a year as a refresher. However, it may be necessary to carry out additional training if there are any changes in the workplace, new equipment is introduced, or if an operator isn’t performing well. OSHA, in addition, recommends the conduction of regular operator performance evaluations as a standard procedure for the identification of the necessity for refresher training.

What signs are there that an electric forklift’s lithium-ion battery might be on the verge of catching fire?

A few of the telltale signs might be unusually hot/flaming battery compartments, strange smells, battery anatomy that has changed in terms of it being larger in size, different noises during charging as well as the low performance of the forklift. In case any of these signs are detected, the power should be cut immediately, the forklift should be isolated, and the maintenance personnel who are qualified should be called.

Is the use of a water-based fire extinguisher recommended in the event of an electric forklift fire?

Water-based extinguishers should never be used to stop running electric forklifts which have caught fire. Water is a good conductor of electricity and can increase the danger. Always use C-class dry chemical or carbon dioxide fire extinguishers especially designed for electrical fires.

What are the guidelines to follow for the disposal of expired fire extinguishers from electric forklifts?

Get in touch with a certified fire equipment company to dispose of it properly. This will be done by them who will either recharge the extinguisher if it is still usable or follow the regulations in the local area for its disposal. Never dispose of extinguishers in regular waste because they are pressurized vessels and can contain dangerous materials.

Where do multiple electric forklifts need to have backup fire extinguishers stored?

It is suggested to have additional fire extinguishers stored at various locations in the facility, especially near charging points and the key forklift operational sectors. Make sure they are easy to see, free of clutter, and follow OSHA height rules when they are mounted.

What kind of proof is recommended to be collected while checking the extinguishers of forklifts?

It is necessary to keep records of the monthly visual checks, yearly maintenance, and also of any issues that have been solved by replacements or by repairs. The file must have the dates of inspection, names of inspectors, serial numbers of the extinguisher, and the response. Save these files for at least one year or as long as the concerned authorities order.