Pneumatic Tire Forklifts Ranked: American Forklifts’ 2026 Inventory Breakdown

Looking ahead to 2026, the demand for durable, all-terrain material handling equipment is more important than ever. Leading this market change is the pneumatic tire forklift, a device not just for lifting but also for handling the rough surfaces at present-day construction sites, timber yards, and shipping terminals.

While the cushioned tire version may only be used on smooth concrete warehouse floors, the pneumatic tire forklifts are the rugged four-wheel-drive vehicles of the industrial world. American Forklifts has assembled a 2026 inventory that expresses a major change toward toughness, operator comfort, and high-capacity performance.

Top American Forklift 2026 Inventory

What Are Pneumatic Tire Forklifts?

Before dliving into the 2026 lineup ranking, one must first understand the difference between the pneumatic tire forklifts and the traditional warehouse lifts. These machines are, in a way, similar to a heavy-duty truck and they have tires that resemble those found on cars or construction equipment.

Hence, they give the operator elevated ground clearance and a broader stance that provide stability on loose gravel, dirt, and uneven asphalt. The American Forklifts stock somewhat distinguishes between two varieties of pneumatic tires: air-filled and solid pneumatic.

On the one hand, air-filled tires provide a comfort and a cushioning effect that helps both the load and the operator to be less affected by the varying terrain thus allowing for a long time of working on a bumpy surface.

On the other hand, the trend of 2026 indicates that solid pneumatic tires, which are simply made of solid, dense rubber, will be the way to go. These tires are practically mock puncture-proof. So, it is they who will not be the cause of any downtime due to flat tires in an environment full of debris such as a scrap or a construction yard.

- Air-Filled Pneumatics: Inflated with pressurized air in an inner tube, gives excellent shock absorption and smooth motion for delicate loads.

- Solid Pneumatics: Made from solid rubber or foam-filled, these tires impart 100% puncture resistance, and are extremely durable in tough industrial environments.

- Class V Designation: The majority of pneumatic forklifts are categorized as Class V (Internal Combustion Engine Trucks), which are known for their outdoor versatility and power.

2. Tier 1 Ranking: The Heavy-Duty Diesel Titans (20,000+ lbs Capacity)

Heavy-duty diesel pneumatic forklifts rank first in the American Forklifts 2026 inventory. These workhorses are indeed the lords of the yard, basically, they are the ones that can take the most brutal situations.

By purchasing different models of the likes of Kalmar or heavy-duty Toyotas, one is basically buying the equivalent of the machine that can lift shipping containers, huge concrete pipes, and steel beams. These forklifts benefit from massive diameter pneumatic tires that help to distribute the weight over uneven ground without the fork truck sinking.

Rather than trying to skip the fuel efficiency aspect when focusing only on getting maximum torque, the 2026 trend is towards the two combined. These giants come equipped with sophisticated diesel engines that comply with the most stringent emission regulations while, at the same time, delivering the raw power necessary for moving 36,000 lbs and beyond.

On these forklifts, the pneumatic tires are, typically, duals (double-width) on the drive axle for maximum traction and stability when the mast is at its highest point.

- Ultimate Load Stability: The broad area covered by the heavy-duty pneumatic tires helps to keep the forklift upright even if it carries a payload of over 30,000 lbs on a roughened surface.

- Strong Low-End Diesel Engines: The diesel engines provide the grunt at the lower end which is required for giving the pneumatic tires enough twisting force when going through different terrains such as mud, snow, and loose gravel.

- Operator Comfort: The working environment for drivers of Tier 1 trucks is very close to a luxe car as cabins are fully enclosed and suspended, in addition to this, the shock-absorbing effect of the pneumatic tires on the rough terrain helps isolate the driver from exterior vibrations.

3. Tier 2 Ranking: The Versatile LPG Yard Forklifts (5,000 – 10,000 lbs)

Below the top versatile models but way ahead in popularity are the mid-range Liquid Propane Gas (LPG) pneumatic tire forklifts that are roughly in the 5000 – 10000 lbs capacity range. The last point of sale for these machines is that they combine two qualities, which are outdoor and indoor, in a very unique way.

The reason for this is that to the extent that they are equipped with pneumatic tires they have the power to be used outdoors and, on the other hand, their low emissions allow for indoor use in well-ventilated locations at the very least. The 2026 collection has “air pneumatic” variants that have greater comfort on the asphalt and solid pneumatic” variants for the places with nails and metal shards.

Additionally, forklifts with these characteristics have a smaller turning radius than the diesel-powered huge machines but at the same time, they retain sufficient ground clearance to go ramps, dock plates that a cushion-tire lift would get hung up on.

- Double-Fuel Mode: This category’s 2026 models offer a big range of operations because they can switch between LPG and gasoline, so running out of one fuel source is no longer a concern.

- All-Terrain Feature: Pneumatic tires provide the capability of moving from a paved loading dock to a gravel laydown area in these lifts without any stoppage.

- Cost-Efficient Maintenance: The combination of an LPG engine and durable solid pneumatic tires drastically cuts down the overall cost of ownership when compared to the diesel counterparts.

4. Tier 3 Ranking: The Emerging Outdoor Electrics (80V Pneumatic)

It was a surprise to many that the high-voltage electric wire pneumatic forklift managed to become one of the 2026 rankings. For a long time, electric forklifts were limited to indoor applications with cushion tires since battery technology was not up to the challenge of the outdoor power drain.

However, American Forklifts now carries 80-volt electric systems combined with aggressive pneumatic tires that match the performance of internal combustion engines. One of the reasons why the electric outdoor pneumatic tire lifts are getting more popular is that they have zero emissions thus making them very suitable for agriculture and food processing industries where the presence of diesel exhaust is considered pollution whilst at the same time having sturdy tires to go across a muddy farmyard.

The electric ones are equipped with pneumatic tires that are designed to reduce the amount of energy used thus increasing battery life while still providing enough grip for outdoor slopes.

- Green Power Outdoor Performing: It gives a business the opportunity to reach its sustainability targets whilst at the same time, carrying out heavy outdoor lifting tasks that used to be done by diesel trucks only.

- Immediate Torque: The electric motors deliver power instantly to the pneumatic wheels, thereby preventing the bogging down that can occur in soft soil.

- Lower Noise Levels: The combination of quiet electric motors and shock-absorbing pneumatic tires lead to a safer, quieter work environment that results in improved communication on the ground.

5. Upkeep and Safety: Protecting Your Pneumatic Forklift Inventory

The operation of a pneumatic tire forklift calls for a unique maintenance program that is different from that of the indoor warehouse lifts. Due to the fact that these machines are used in rough environments, it is the tires that become the foremost safety element.

For the air-filled pneumatic tires, one important thing about air pressure is that it is not only for fuel economy but it is also a factor that decides stability greatly. The reason for this is that unfair tire pressure will cause a change in the center of gravity and when you will be lifting a heavy load at a height, this can cause a tip-over.

According to American Forklifts, tire health monitoring is an enormous part of the 2026 inventory. “Chunking,” which happens when pieces of the tire rubber are torn off as a result of rough terrain, is one of the downsides of solid pneumatics that must be fixed straight away in order to prevent the vibration from getting too much.

Besides that, pneumatic forklifts’ wheel lug nuts are subject to great tension thus they should be re-torqued frequently, especially those on the drive axle.

- Pressure Checks: It is vital that air-filled tires are checked regularly to make sure that the forklift is not tilted which in turn could lead to mast tilt.

- Tread Pattern Check: It is outdoor surfaces that cause accelerated wear of tread patterns. When a pneumatic tire is bald, traction on wet ramps is lost, which causes slides.

- Rim and Lug Nut Tightlyness: The nature of outdoor work is such that it can loosen up wheel hardware; hence, it is necessary to perform a visual check of the rim condition during pre-shift inspections daily.

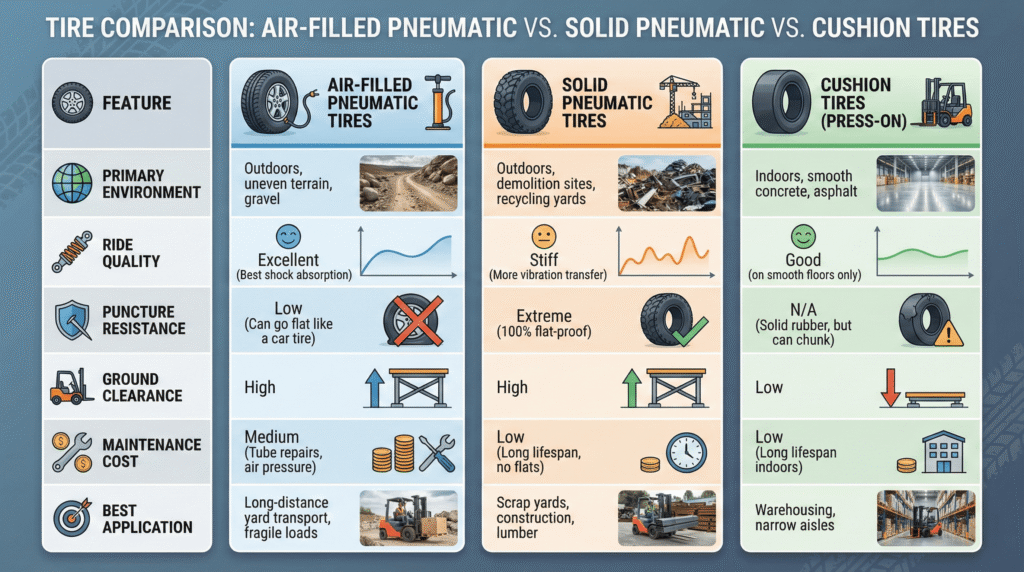

Comparison: Air Pneumatic vs. Solid Pneumatic Tires vs. Cushion Tires

To make it easier for the customers of 2026 to find their way through the American Forklifts inventory, the following chart displays the main differences between the different types of tires along with pneumatic tire forklifts. Knowing the characteristics of each will help you decide which is best for the terrain you have.

| Feature | Air-Filled Pneumatic Tires | Solid Pneumatic Tire Forklifts | Cushion Tires (Press-On) |

| Primary Environment | Outdoors, uneven terrain, gravel | Outdoors, demolition sites, recycling yards | Indoors, smooth concrete, asphalt |

| Ride Quality | Excellent (Best shock absorption) | Stiff (More vibration transfer) | Good (on smooth floors only) |

| Puncture Resistance | Low (Can go flat like a car tire) | Extreme (100% flat-proof) | N/A (Solid rubber, but can chunk) |

| Ground Clearance | High | High | Low |

| Maintenance Cost | Medium (Tube repairs, air pressure) | Low (Long lifespan, no flats) | Low (Long lifespan indoors) |

| Best Application | Long-distance yard transport, fragile loads | Scrap yards, construction, lumber | Warehousing, narrow aisles |

FAQs on Pneumatic Tire Forklifts

Can I put pneumatic tires on a cushion tire forklift?

Simply no. Changing the tires on a forklift made for cushion tires with pneumatic tires is not a viable option for several reasons. The two types of forklifts have different frames and axles; cushion tire forklifts have smaller wheel wells and different bolt patterns. Besides, the turning radius and ground clearance are designed for that particular tire type. Doing this swapping may result in the loss of stability and safety of the machine.

Do solid pneumatic tires ride rougher than air-filled ones?

The short answer is yes. Solid pneumatic tires provide a less comfortable ride when compared to air-filled ones. This is one of the cons of this type of tire as the solid rubber-only tires transfer more vibration in both the vehicle and operator, from the ground, than air-filled pneumatics. Nevertheless, this is frequently a necessary compromise to get rid of the problem of puncture resistance when working in an environment full of sharp objects like nails, metal scraps, or jagged rocks.

Are pneumatic tire forklifts suitable for indoor use?

Pneumatic tire forklifts can be used indoors but are not very suitable for warehouses as they tend to be less efficient due to their Flipping to using cushion tire forklifts would give you a better return in terms of the working space you can fit. The reason for the less efficiency lies in the fact that pneumatic tire forklifts have a larger turning radius and therefore take up more space while operating. At the same time, they have a bigger chassis than the cushion ones however if there are large open spaces in your facility or the forklift has to make regular trips from an indoor to an outdoor location (like a loading dock), the pneumatic tire forklift is the best all-around solution.

How long do solid pneumatic forklift tires last?

They generally wear out at a rate that is half or even one-third the rate at which air-filled pneumatic tires lose their tread. Because these tires are produced from dense, very wear-resistant rubber and also cannot be flat, they are very tough. The overall durability of the tire will, to a great extent, depend on the number of usage hours, and the type of abrasive material over which it is used, but normally in the long term solid pneumatics prove to be the most cost-effective alternative for heavy-duty applications.

Can I fill my air pneumatic tires with foam?

What you say is right, foam-filling has become a widely used treatment for air pneumatic tires. The method of doing this is by injecting a liquid polyurethane polymer into the tire, which then hardens to form a solid core that is very similar to rubber. In doing so, the tire that was previously air-filled is now more like a solid one and it would be nearly impossible for it to get punctured, thus saving you a lot of frustration and money if you are working in an environment that makes constant use of forklifts. It also adds extra weight to the tire which sometimes can increase stability.

What is the difference between Class IV and Class V forklifts?

The major difference has to do with the tires as well as the intended environment for use. Class IV forklifts (internal combustion, cushion tires) are mainly designed to be used indoors on smooth, dry surfaces. Class V forklifts (internal combustion, pneumatic tires) are outdoor vehicles intended for use on rough, uneven, or wet surfaces. The pneumatic range offered by American Forklifts is mostly Class V.

Why are pneumatic tires better for gravel?

This is because pneumatic tires are bigger and have deeper treads that provide more traction. In contrast, a cushion tire has both a small contact area and is made of a smooth rubber; therefore, on gravel, a cushion tire will simply sink and spin resulting in the forklift becoming stuck very quickly. Pneumatic tires behave more like hiking boots on loose ground, they “float” over the surface and use their cleats to grip the ground similar to tractor tires.

Conclusion – Pneumatic Tire Forklifts

American Forklifts 2026 inventory breakdown presents a very clear signal about the direction of the material handling industry: machines that can handle any kind of terrain will be in high demand for pneumatic tire forklifts. Regardless of whether you are thinking about the enormous lifting power of diesel heavy-duty titans, the adaptable functionality of LPG yard trucks, or the top-notch efficiency of 80V electrics, what these have in common basically is the pneumatic tire. These tires are the enabling factor of outdoor productivity. They are the connecting link between the warehouse and the work site. Businesses can take full advantage of the benefits of air-filled and solid pneumatically catered machines if they know well which one is which.